psi

bar

MPa

16 309255

Pressure Control Repair

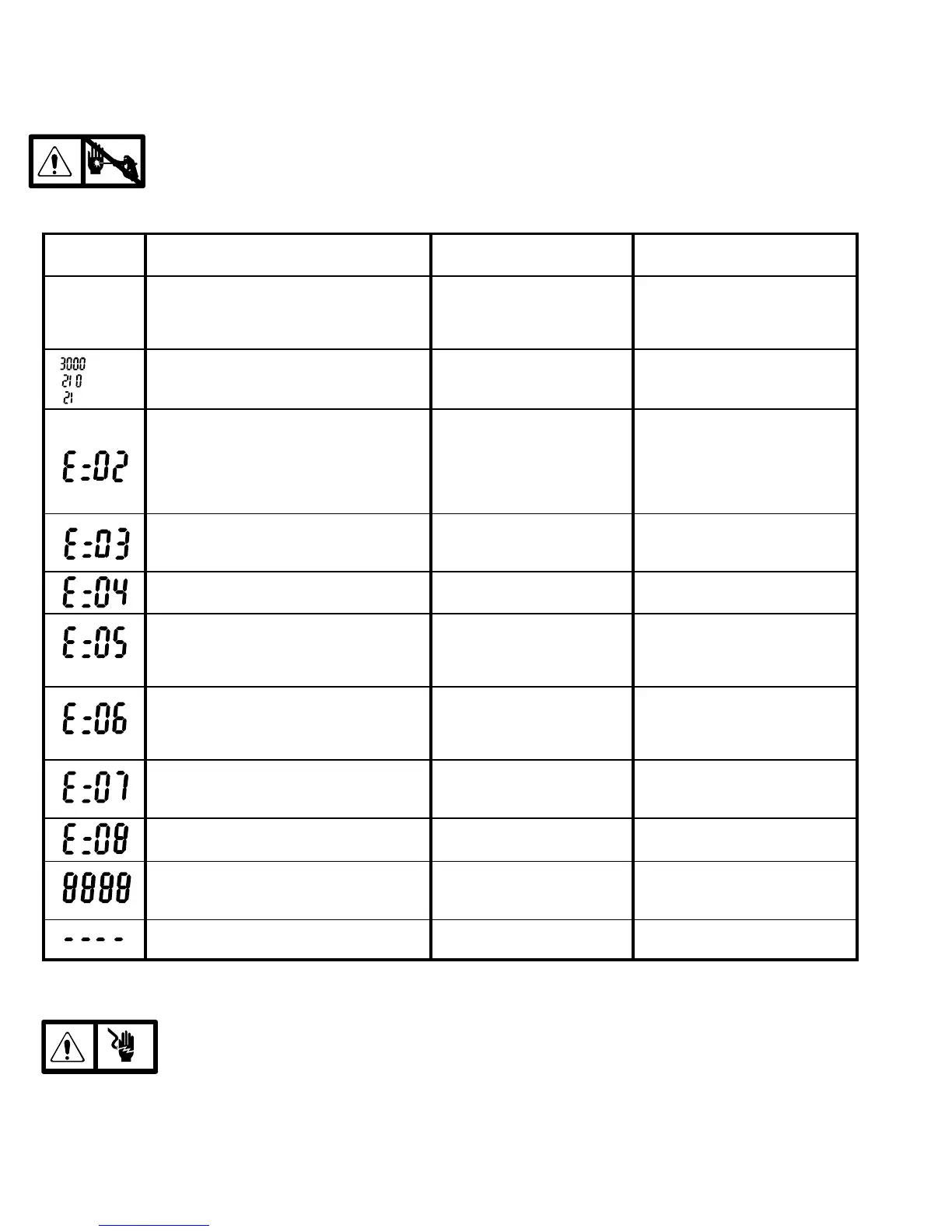

Digital Display Messages (Not available on all sprayers)

No display does not mean that sprayer is not pressurized. Relieve pressure before repair; page 4.

DISPLAY* SPRAYER

OPERATION

INDICATION ACTION

No Display Sprayer may be pressurized. Loss of power or display not

connected

Check power source. Relieve

pressure before repair or disas-

sembly. Verify display is con-

nected.

Sprayer is pressurized. Power is applied.

(Pressure varies with tip size and pressure

control setting.)

Normal operation Spray

1. Sprayer stops. Power is applied.

2. Sprayer stops. Power is applied.

3. Sprayer continues to run

1. Exceeded pressure limit of

4500 psi. Sprayer is pres-

surized.

2. Sprayer is not pressurized

3. Pressure rise nears 4500 psi

1. Remove any filter clogs or flow

obstructions. Lock gun trigger

open if using AutoClean valve.

2. Replace transducer

3. Replace control board

Sprayer stops. Power is applied. Pressure transducer faulty,

bad connection or broken

wire.

Check transducer connections

and wire. Replace transducer or

control board, if necessary.

Sprayer stops. Power is applied. Line voltage too high Check for voltage supply problem

Sprayer stops. Power is applied. Too much motor current Check for locked rotor, pump ob-

struction, damaged drive train,

shorted wiring or motor. Repair or

replace failed parts.

Sprayer stops. Power is applied. No operation, motor over

heated or unplugged

Allow sprayer to cool. Correct

cause of overheating. Verify mo-

tor is plugged into motor control

board

Sprayer stops. Power is applied. Pressure greater than

2000 psi (138 bar, 14 MPa)

while in Flush Timer Mode

Make sure spray gun is triggered

and prime valve is open when us-

ing AutoClean

Sprayer stops. Power is applied. Low line voltage Check for voltage supply problem

Power is applied. Digital display switches are

not set

Set switches on back of digital

display to appropriate settings.

Fig. 12, page 15.

Sprayer may be pressurized. Pressure less than

200 psi (14 bar, 1.4 MPa)

Increase pressure as needed

*Error codes also appear on control board as a blink-

ing red LED. LED is an alternate to display.

Electric shock hazard; page 4.

1. Remove four screws (60) and cover (49).

2. Turn sprayer ON. Count LED blinks. Blink count is

the same as error code (E=0X) in preceding

Digital Display Messages table.

3. Follow instructions in table.

After a fault, do following steps to restart sprayer:

1. Correct fault condition

2. Turn sprayer OFF

3. Turn sprayer ON

Loading...

Loading...