‘ROBLEM

1 CAUSE

[ SOLUTION

AI. Not enough paint pressure (See Pro-

1. Pressure setting too low

1. Increase.

blem III also.)

2. Spray tip too big or worn

2. Change tip; see manual 307321.

3. Motor brushes worn

3. Replace. See page 14.

4. Pressure control or motor

4. Return for repair.

damaged

‘Ill. Poor spray pattern

1. Clogged spray tip

2. Pressure setting too low

3. Outlet filter or hose partially

clogged

4. Spray tip too big or worn

5. Paint supply low or pail empty

6. Paint too thick

1. Clean. See manual 307321.

2. Increase.

3. Clean; see manual 367-273.

4. Change tip; see manual 307-321.

5. Fill; reprime to remove air.

6. Thin per paint manufacturer’s

recommendations.

IX. Spitting from spray gun

X. Static sparking from gun

1. Paint supply low or pail empty

2. Sprayer sucking air or gun

needle not seating

1. Sprayer or work not grounded

1. Fill, reprime to remove air.

2. Tighten fittings; repair gun; see

manual 307-614.

1. Check hose continuity and elec-

trical ground connection.

(a) Engage gun safety latch, Depress manual reset button on top of pressure control. If the sprayer continues to shut

off,

reduce

spraying pressure. If the problem isn’t corrected, return for repair.

(b) Freezing results from failure to replace water-base paint or flushing water with mineral spirits at shutdown.

(cl Overpressurization results from (1) using less than 50 ft (15.2 m) of nylon spray hose; (2) using wire braid hose: (3) adding a

shutoff device between filter and main hose; (4) plugging the main fluid outlet of the filter and using drain valve as a shutoff; and

(51 a clogged or incorrectly assembled filter.

(d) EIIesr;z to keep packing nut l/3 full of Throat Seal Liquid to help prevent premature wear of throat packings and paint drying on

DISPLACEMENT PUMP REPAIR

Tools Needed:

Heavy duty vise

718” open end wrench

2’ open end wrench

Plastic mallet

Small screwdriver

Before doing this

procedure, follow the Pressure

Lh:yNG-i

Relief Procedure Warning on page 14 to reduce

the risk of an injection injury, injury from moving

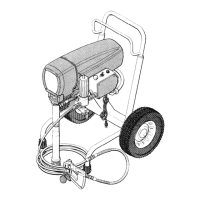

Removina the Puma

(Refer to Fia 8.1

1.

2.

3.

4.

5.

Flush the pump,‘if possible, &d relieve pressure

again. Stop the pump with the piston rod (223) in

its lowest position.

Unscrew the suction tube (42) from the pump. Hold

the

wrench on the pump intake valve (222) to keep

the pump from loosening.

Unscrew the hose (47) from the nipple (48) on the

pump outlet and remove the hose.

Use a screwdriver to push the retaining spring (35)

aside and push out the pin (20).

Loosen the locknut (38) and unscrew the pump

from the bearing housing (27).

Fig 8

307-643 15

Loading...

Loading...