Repair manual GRAMMER seat suspension MSG95EAC – November 2012

Material no. 1 277 338

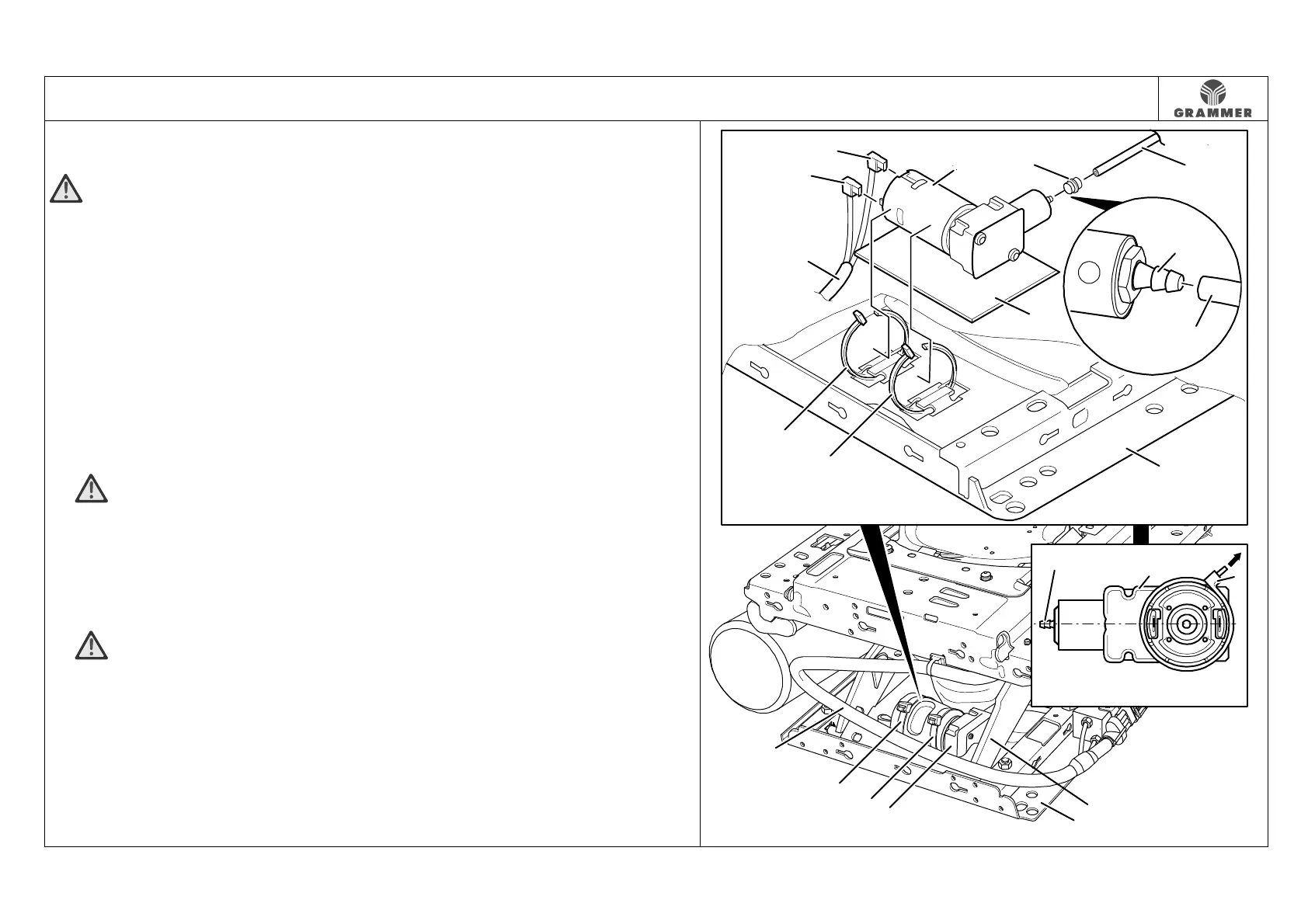

3.8 Compressor – removal and installation

Page 1 of 2

Removal and installation

ATTENTION Leak test!

Perform a hydrostatic test of the seat

suspension upon installation of the

compressor (1). To do this, apply a 60 kg

load to the seat suspension for 24 hours.

The lowering within this time must not

exceed 15 mm.

1 Remove the seat (see Chapter 3.1).

2 Remove the bellows at the lower

suspension part (see Chapter 3.3),

push it upwards and fix it in this

position.

3 WARNING Risk of crushing!

Move the seat suspension to the

highest position and secure at the back

between the swinging structure and the

lower suspension part by means of

suitable spacers.

4 WARNING The pressure in the

pneumatic system may cause injury!

Vent the pneumatic system before

removing the compressor (1).

5 Mark and remove two right-angle plugs

(8).

Installation notes:

• Reconnect the electrical connection

according to the marking.

• When establishing the electrical

connection, the cable output of the

compressor cable (7) at the right-angle

plug (8) must point downwards.

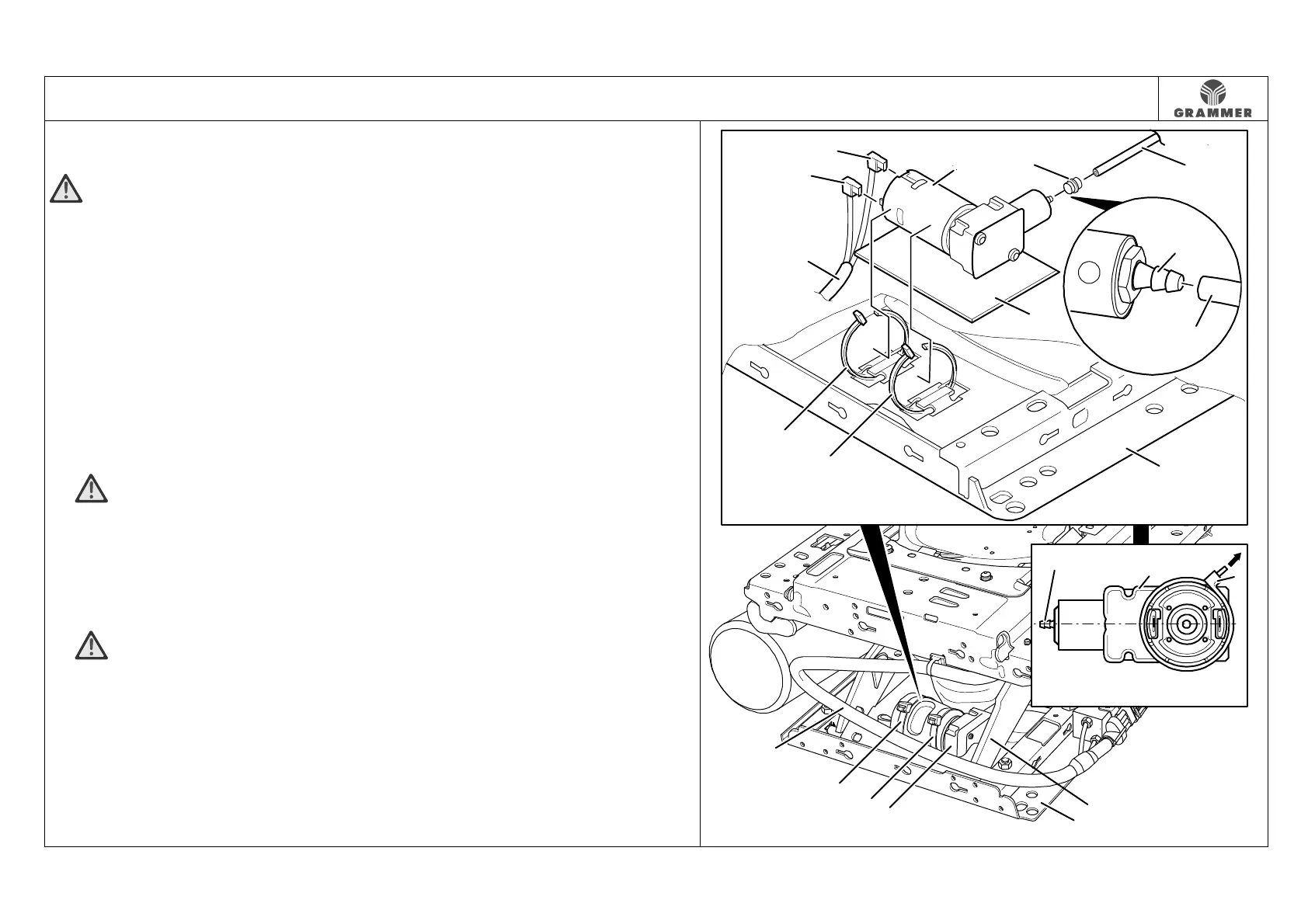

6 Mark the points where the compressor

(1) is secured to the lower suspension

part (5) with two cable ties (6) and

remove the cable ties (6).

Installation notes:

• Run the cable ties (6) through the

corresponding cut-outs in the lower

part of the suspension (5) in such a

way that the locking head of the cable

ties (6) points forwards (arrow).

• Loosely close the cable ties (6) in

such a way that the compressor (1)

can still be moved.

• Align the compressor (1) so a

collision with the swinging structure (9)

is avoided and then use pliers to

tighten the locking head of the cable

ties (6) to 360 ± 30 N in the tensile

direction.

2864

1

8

6

6

4

7

5

8

2

3

3

1

2

1

6

1

5

6

6

7

9

1

10

10

Loading...

Loading...