Repair manual GRAMMER seat suspension MSG95EAC – November 2012

Material no. 1 277 338

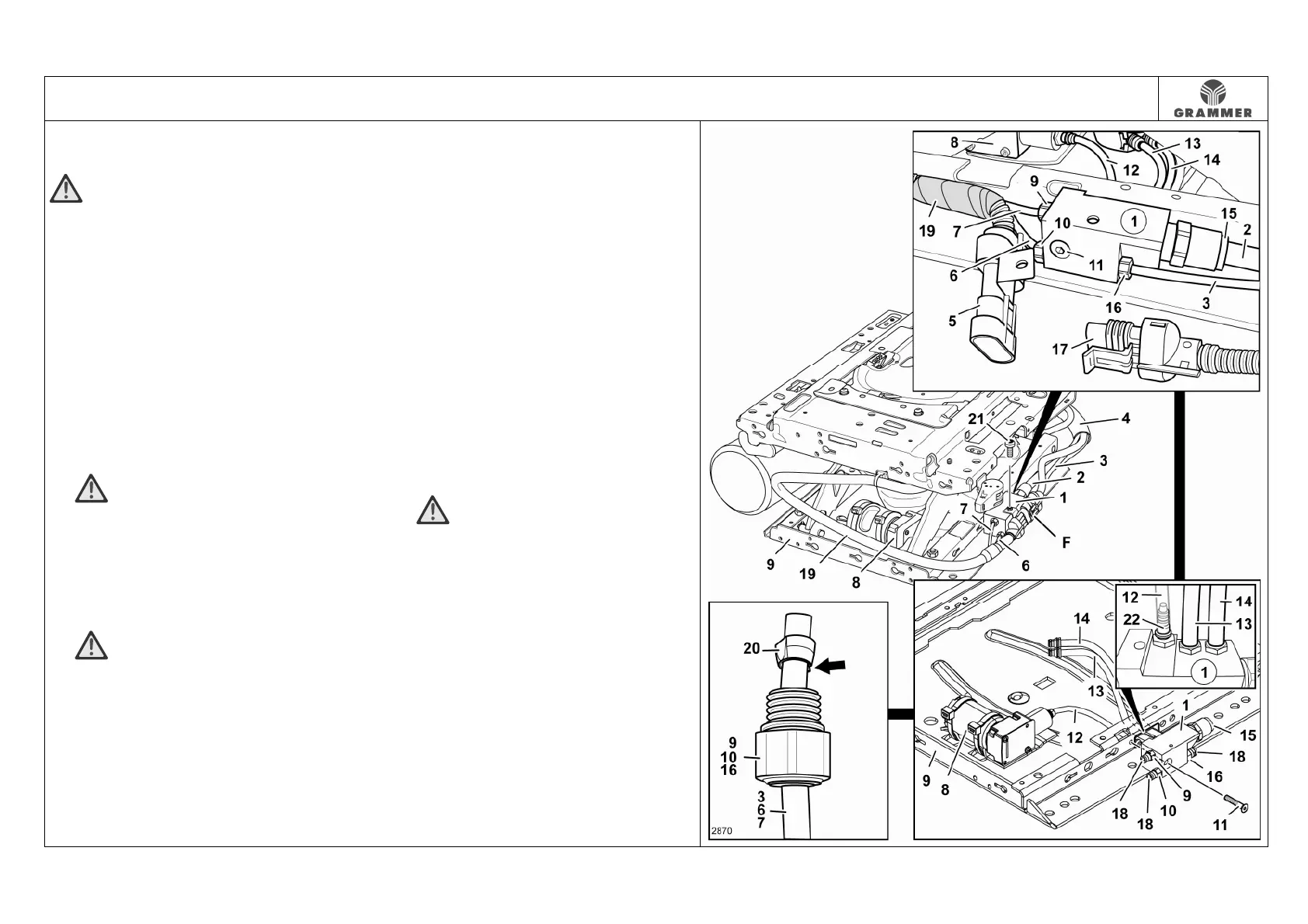

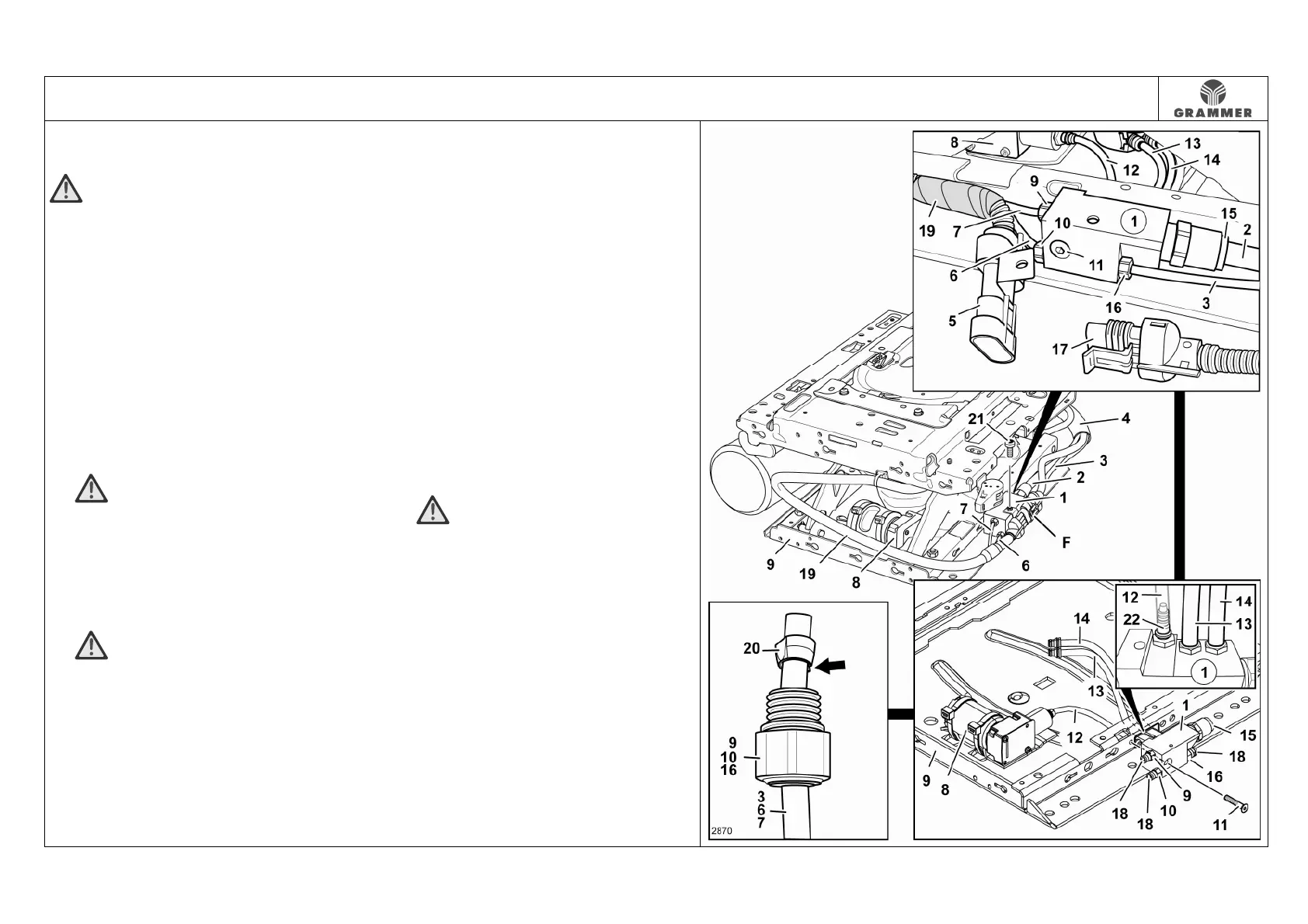

3.14 Air distributor – removal and installation

Page 1 of 2

Removal and installation

ATTENTION Leak test!

Perform a hydraulic test of the seat

suspension upon installation of the air

distributor (1). To do this, apply a 60 kg

load to the seat suspension for 24 hours.

The lowering within this time must not

exceed 15 mm.

1 Remove the seat (see Chapter 3.1).

2 Remove the bellows at the lower

suspension part (see Chapter 3.3),

push it upwards and fix it in this

position.

3 WARNING Risk of crushing!

Move the seat suspension to the

highest position and secure at the back

between the swinging structure and the

lower suspension part by means of

suitable spacers.

4 WARNING The pressure in the

pneumatic system may cause injury!

Vent the pneumatic system before

removing the air distributor (1).

5 Remove the air hose (12) from the

compressor (8) (see Chapter 3.8).

6 Remove the air hoses (13 and 14) from

the air spring (see Chapter 3.10).

7 Disconnect the electrical connection

between socket (17) and plug (5).

8 Remove the screw (21) from the air

distributor (1) and remove the plug (5)

from the air distributor (1).

Installation note:

Screws (20), 3.5 ± 0.5 Nm

9 Unscrew countersunk screw (11).

Installation note:

Countersunk screw (13), 10 ± 2 Nm

10 Mark three quick-release fastener

screws (9, 10, 16) and unscrew them

from the air distributor (1).

11 ATTENTION Damage!

Take care not to damage the air

hoses (3, 6, 7).

Bend open the retaining ring (20) at

the opening (arrow) and pull it off the

air hoses (3, 6, 7).

Loading...

Loading...