24

Grant Vortex Oil Boilers

4 - GENERAL BOILER INFORMATION

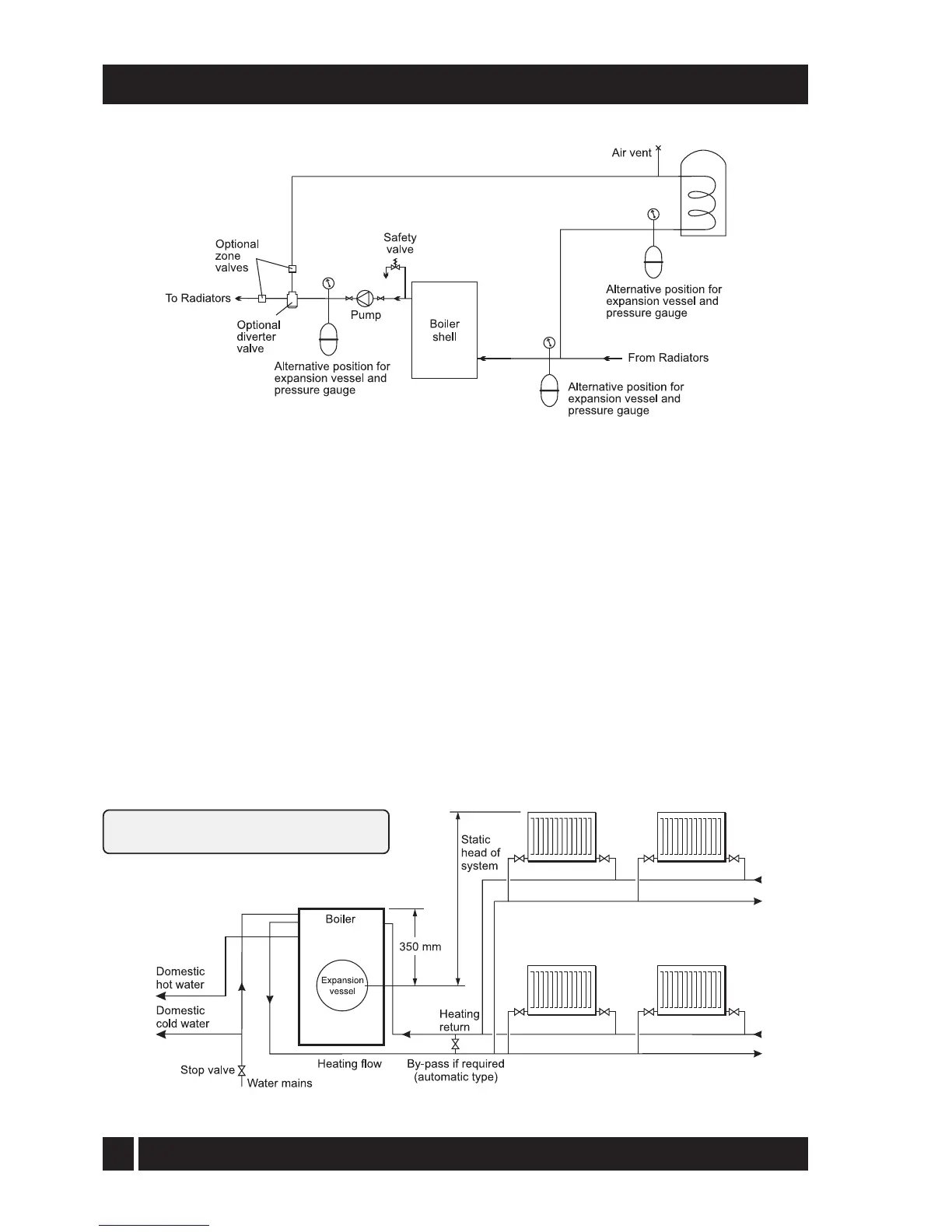

Fig. 13 - Sealed system

6 Provision should be made to replace water lost

from the system. This can be done manually (where

allowed by the local water undertaking) using an

approved filling loop arrangement incorporating a

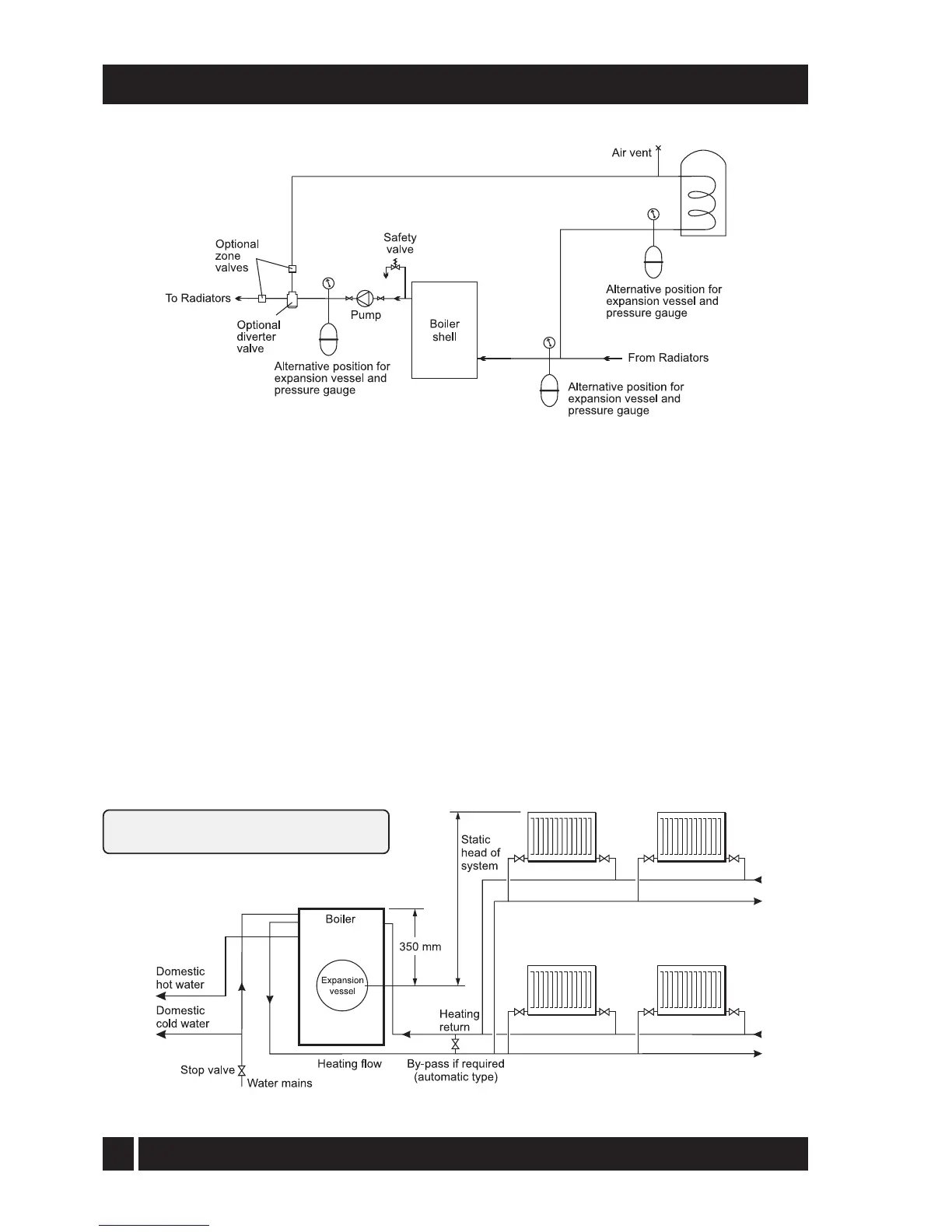

double check valve assembly (as supplied fitted on

System models).

7 An automatic air vent should be fitted to the

highest point of the system.

8 The system design pressure (cold) should be between

0.5 and 1.0 bar. This pressure is equivalent to the

maximum static head (see Fig. 14) in bar + 0.3 (1 bar

= 10.2 metres of water).

9 If thermostatic radiator valves are fitted to all

radiators, a system by-pass must be fitted. The by-

pass must be an automatic type.

Fig. 14 - Sealed system boilers

If thermostatic radiator valves are fitted, the

system must incorporate an adequate by-pass.

10 Filling of the system must be carried out in a

manner approved by the local Water Undertaking.

Where allowed, the system may be filled via the

filling loop supplied (the loop arrangement

includes a double check valve assembly).

11 All fittings used in the system must be able to

withstand pressures up to 3 bar.

12 Radiator valves must comply with the requirements

of BS 2767(10):1972.

13 One or more drain taps (to BS 2879) must be used

to allow the system to be completely drained.

14 The expansion vessel is connected via a flexible

hose to allow it to be moved to gain access to the

baffle cleaning cover. When replacing the vessel,

care should be taken to ensure that the flexible

connecting hose is not twisted.

Loading...

Loading...