31

Grant Vortex Oil Boilers

Expansion vessel pressure - System models

5.6

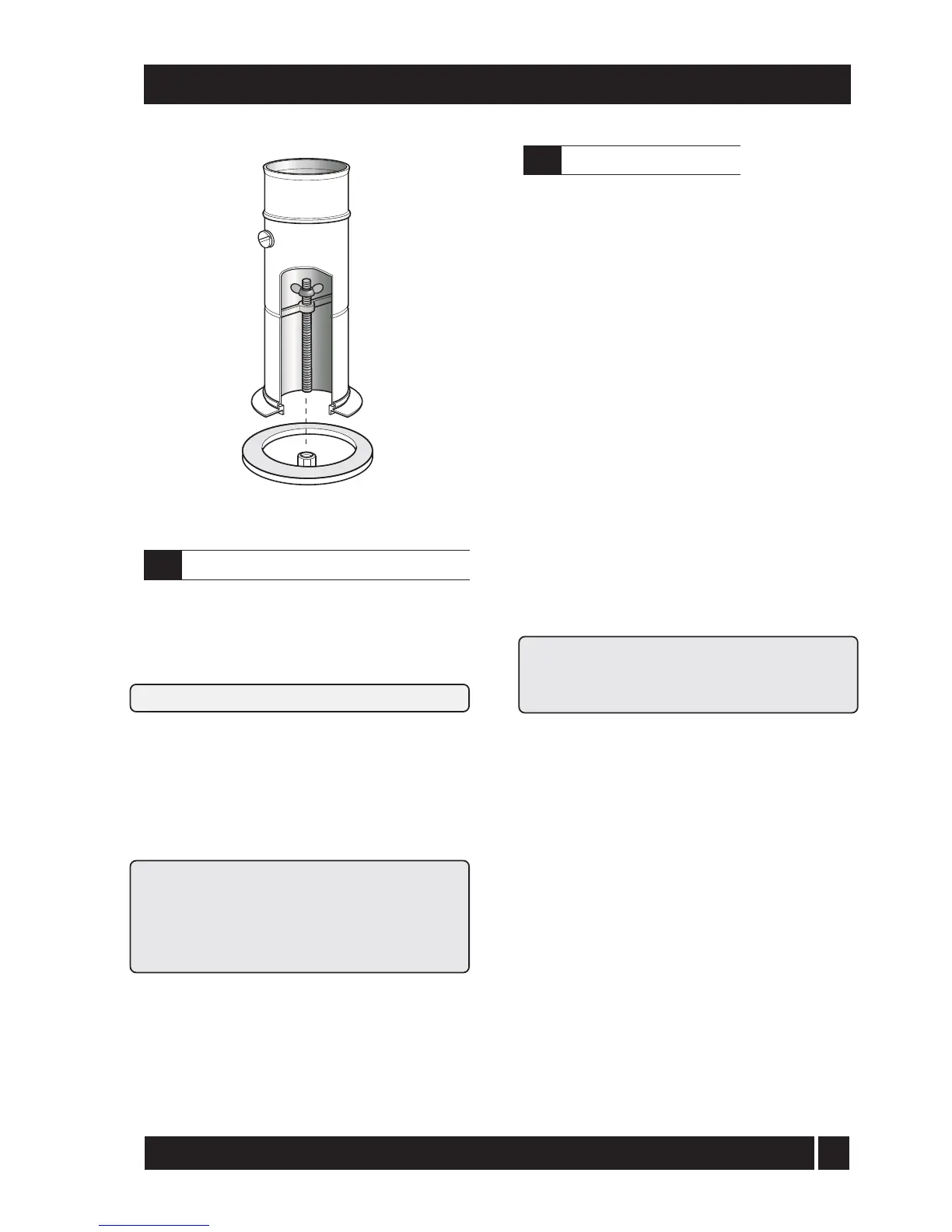

Fig. 21 - Boiler flue connector

5 - BOILER INSTALLATION

The expansion vessel fitted, is supplied with a charge

pressure of 1.0 bar (equivalent to a max. static head of

10.2 metres). The charge pressure must not be less

than the actual static head at the point of connection.

Do not pressurise the vessel above 1.5 bar.

The air pressure in the vessel must be checked annually.

The central heating system volume, using the expansion

vessel as supplied, must not exceed the recommended

volumes. If the system volume is greater, an extra

expansion vessel (complying with BS 4841) must be

fitted as close as possible to the central heating return

connection on the boiler. The charge pressure of the extra

vessel must be the same as the vessel fitted in the boiler.

Refer to BS 7074:1 for further guidance.

The air charge pressure may be checked using a tyre

pressure gauge on the expansion vessel Schraeder

valve. The vessel may be re-pressurised using a

suitable pump. When checking the air pressure the

water in the heating system must be cold and the

system pressure reduced to zero.

It is recommend that the boiler should be connected to

a switched mains power supply from a programmer or

control system. If a Grant plug-in programmer is used,

a permanent 240 V mains supply (fused at 5 Amp)

must be taken to the boiler. A three core cable is

required to connect the boiler terminal block to the

live supply. Refer to Sections 9.5 and 9.6 for typical

control system wiring diagrams.

1 Lift off the boiler case top panel, if it has not

already been removed.

2 Remove the top of the control panel (Utility

models) or the wiring cover (on Kitchen models)

and open the cable clamp. Route the supply cable

through the hole in the rear panel (using the

grommet supplied) up to the control panel, pass it

through the cable clamp and connect to the boiler

terminal block (refer to Section 9) as follows:-

Brown to live (terminal 1)

Blue to mains neutral (terminal 2)

Green/Yellow to mains earth (terminal 3)

Kitchen and Kitchen System models - If the plug-in

programmer is not fitted, ensure that the RED wire

link, between terminals 1 and 8 (1 and 10 on System

model) on the boiler terminal block is fitted.

Note: Ensure that the route and length of the cable

is such that the boiler front cover plate can be

easily removed without disconnecting the supply

cable from the terminal block.

3 If the optional plug-in electronic programmer is to

be fitted, follow the fitting instructions given in

Section 5.8 at this point.

4 Secure the cable in the cable clamp.

5 Place the wiring cover in position over the terminal

block, taking care not to trap any wires and secure

in position with the two M4 screws provided.

6 Ensure that all external wiring is adequately supported.

Do not switch on the electricity supply at this stage.

Connect the power supply

5.7

Loading...

Loading...