4 Boiler Installation Information

12

Boiler Installation

Information

4.1 Introduction

The boiler is supplied already fully

assembled with the flue terminal guard

supplied loose inside the boiler.

4.2 Boiler Location

1. The External Combi boiler must

stand on a solid, level surface

capable of supporting the weight of

the boiler when full of water, e.g. a

prepared concrete standing, paving

slabs bedded down on sand /

cement, or similar.

2. The Module can be installed either

against the building or ‘free standing’

some distance away from the

building.

3. The Module must be positioned

such that the required clearances

from the low level flue outlet, as

shown in Figure 9-1, are achieved.

4. Adequate clearance must be left

around the boiler for servicing. In

particular, a minimum clearance of

600mm above the boiler for removal

of the top panel and 600mm at

each end allow for access to the

burner and condensate trap.

4.3 Preparation for Installation

1. Carefully remove the packaging

from the boiler and remove it from

the transit pallet.

2. Remove the case top panel and also

the front and rear panels, as required.

3. The flue may exit the boiler from

the left, right or rear of the casing.

Carefully press out the pre-cut

section on the side or end casing

panel to provide the opening in the

required position for the flue to pass

through the casing.

Fit the cover panel (with the round

flue exit hole) over the square flue

opening in the casing. Fit the circular

rubber sealing grommet provided

into the hole in the cover panel

before fitting the flue terminal section.

4. Slacken the wing nuts holding the

flue elbow and rotate the elbow to

the required direction for the flue to

exit the casing.

5. Push the end of the flue terminal

section with the red seal through the

seal in the casing. The terminal has

been factory lubricated. Take care not

to dislodge or damage the red seals.

6. Carefully insert the terminal into the

flue elbow until the bend of the

terminal contacts the outer casing,

then, pull the terminal forward

approximately 25mm and rotate the

bend so that the outlet is horizontal.

Rear Exit - The flue must discharge

away from the building.

Side Exit - The flue should discharge

towards the rear of the casing to

prevent flue gases reentering the

boiler casing through the air inlet

vents on the casing front door.

The flue terminal must be fitted

horizontally to prevent dripping from

the end of the terminal.

7. Tighten the wing nuts holding the flue

elbow and fit the stainless steel flue

guard using the two screws provided.

8. The top panel of the casing has

been designed so that it may be

fitted to create a slight slope away

from the side positioned against the

wall. To tilt the top panel, loosen the

four top panel casing screws, one at

each corner and push down on the

side furthest from the wall. Tighten

the screws. See Figure 4-1.

4.4 Installing the Boiler

1. If the boiler is to be fitted against the

wall, prepare the wall to accept the

heating system pipework. To mark

the wall for drilling, refer to Figure

2-1 for the positions of the pipework

openings in the enclosure sides.

Pipework should be insulated where

it passes through the wall into the

boiler enclosure.

2. A painted steel wall flashing strip is

supplied with the boiler to cover the

gap between the wall and the boiler

casing. It should be secured to the

wall leaving a gap of 30mm

between the bottom edge and the

top of the casing top panel, to allow

removal of the top panel for

servicing.

3. If the boiler is to be installed ‘free

standing’ (that is, away from a wall)

and the pipework run underground,

push out the ‘knock-outs’ to open

the required pipe openings in the

base of the boiler enclosure.

Using a sharp knife, cut through the

polystyrene in the base, around the

edge of the holes, to allow the flow

and return pipes to enter the

enclosure.

A spare blanking plate with a 112mm

diameter hole is supplied with the

Outdoor Vortex Combi boilers. This is

intended to provide an opening into

the boiler if a 110mm soil pipe is

used as a pipe duct through the wall.

!

NOTE

!

NOTE

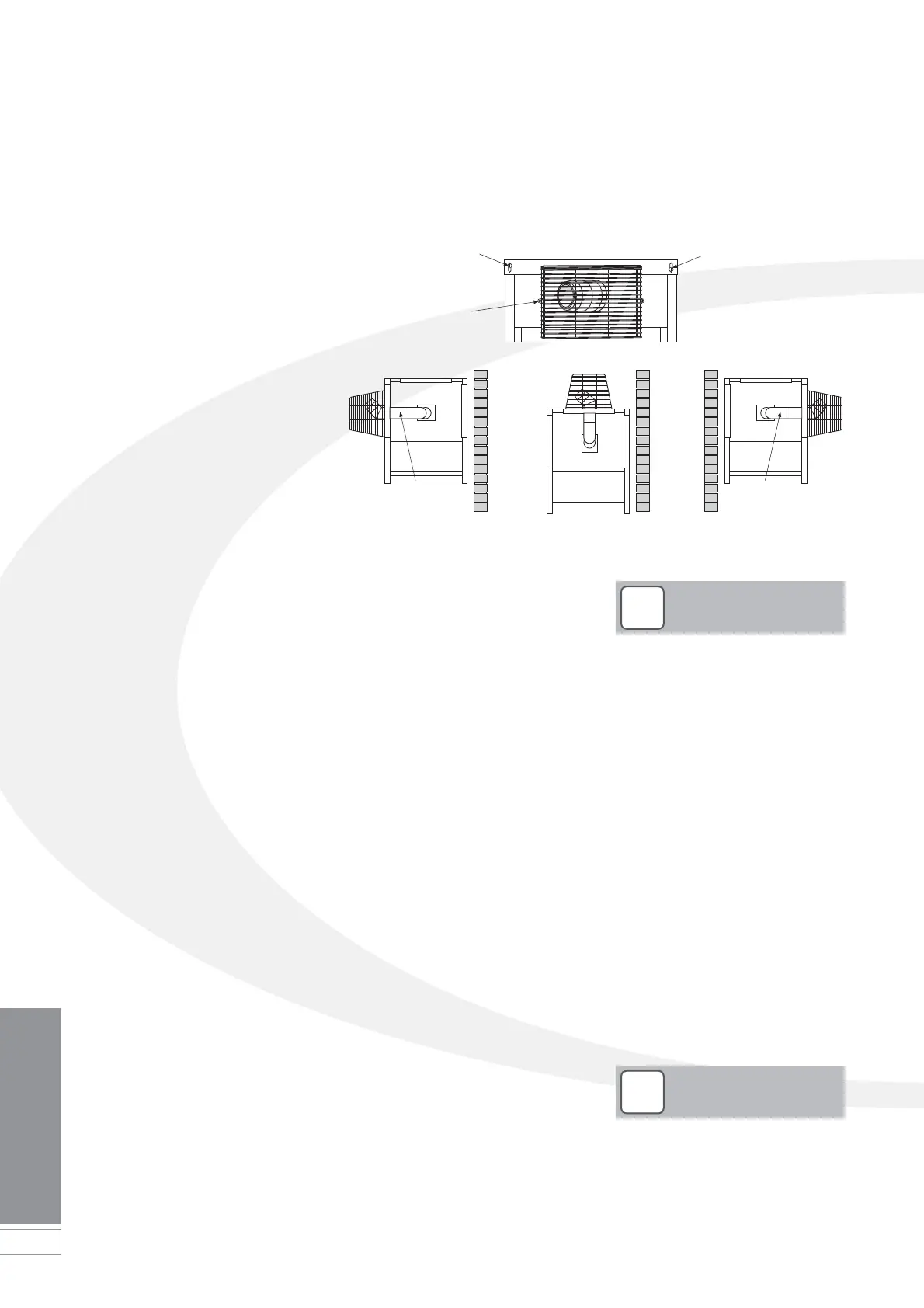

Figure 4-1: Standard supplied flue

Top panel

fixing screw

Top panel

fixing screw

Top panel

fixing screw

Angle top panel to

slope away from wall

using slots provided

Terminal guard

fixing screw

(one each side)

End of terminal

with red seal

Flue elbow

Rear Exit Right ExitLeft Exit

Loading...

Loading...