GB - 27

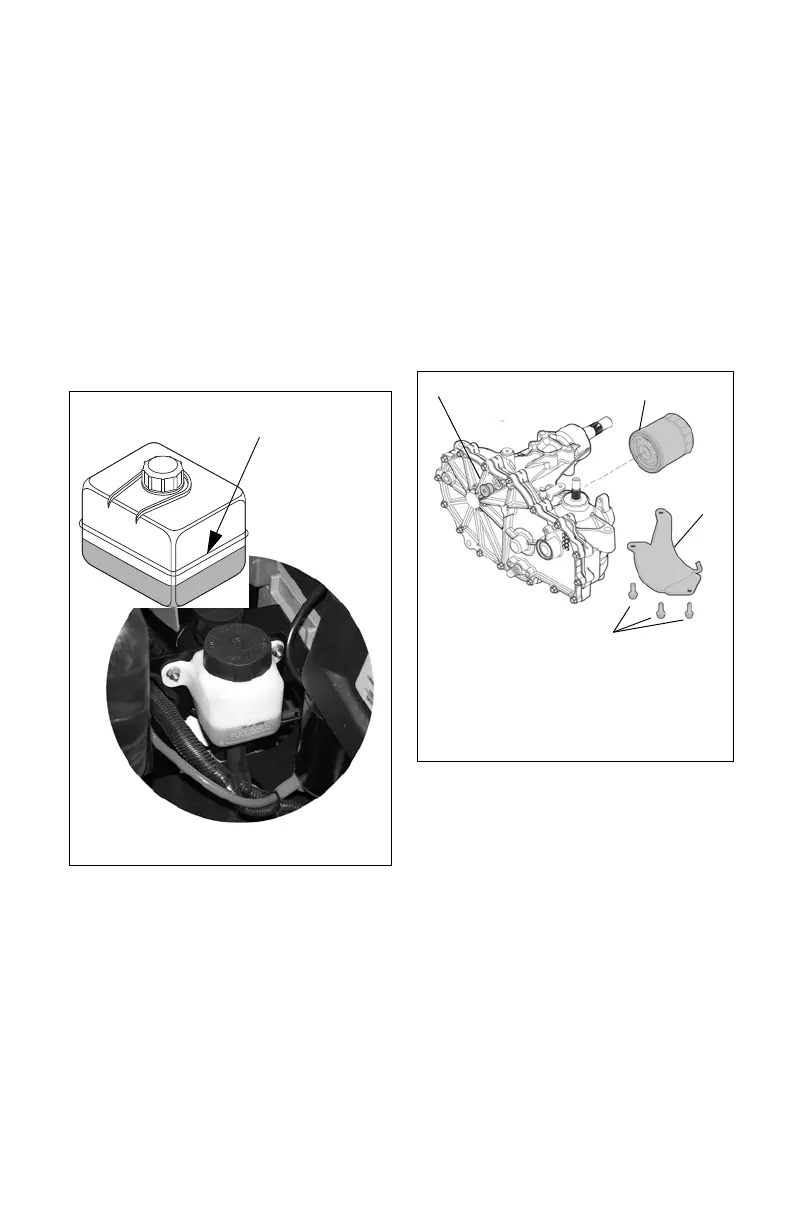

Check Hydraulic Fluid Level

(Figure 25)

Check the system with the unit cold and

p

arked on a flat, level surface.

Then run the unit for about one minute and

recheck th

e levels.

To Add Hydraulic Fluid:

(Figure 25)

1. Remove the cap from the expansion

t

ank.

2. Fill the expansion tank with 20W-50

engine oil

with an SL API classification

until oil level reaches the cold fill line on

the tank.

3. Install the expansion tank cap and then

pur

ge the system. See “Purging the

Hydraulic System” on page 28.

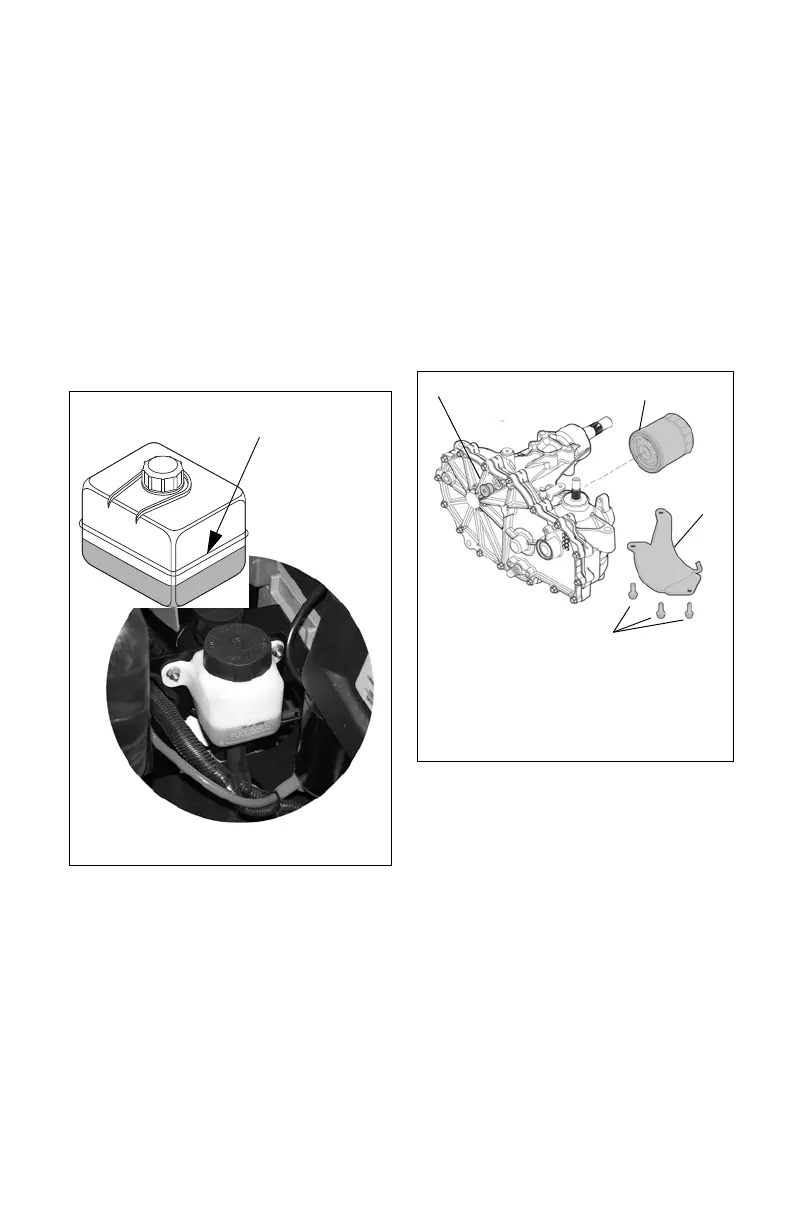

Change Hydraulic Fluid and Filter

(Figure 26)

NOTE: C

hange hydraulic fluid and filter after

the first 75 hours of operation and then every

400 hours. Use 20W-50 engine oil with an SL

API classification.

1. Place container under oil filter to catch

oil.

2. Remove the filter guard and oil filter from

the tr

ans axle.

3. Remove the oil drain plug or fitting from

the inlet port

and allow the trans axle to

drain completely.

4. Clean the filter mounting surface and

then

lubricate rubber gasket on new oil

filter with clean hydraulic oil.

5. Spin new oil filter onto filter housing until

it makes cont

act. Tighten oil filter

another 3/4 turn.

6. Install the filter guards removed in

step 2. Tighten the mounting screws to

5.38 lbf-ft (7.3 N•m).

7. Fill with 20W-50 engine oil with an SL

API classification

until oil appears at the

bottom of the drain plug (about 2 quarts

per trans axle). Install the drain plug and

tighten it to 14.97 lbf-ft (20.3 N•m).

8. Repeat steps 1 – 7 for the other trans

axle.

9. Follow the instructions in “To Add

Hydraulic Fluid:” on page 27.

Figure 25

The hydraulic fluid should be at the cold

fill line of the expansion tank.

Figure 26

1. Drain Plug

2. Oil Filter

3. Filter Guard

4. Mounting Hardware

1

4

3

2

Loading...

Loading...