Engine Manual 4

III. Before Operation

PRE-OPERATION CHECKS

For your safety, and to maximize the service life of your equipment, it is very important

to take a few moments before you operate the engine to check its condition. Be sure to

take care of any problem you nd, or have your servicing dealer correct it, before you

operate the engine.

WARNING

Improperly maintaining this engine or failing to correct a problem before operation,

could cause a malfunction in which you could be seriously injured. Always perform

a pre-operation inspection before each operation and correct any problem.

Before beginning your pre-operation checks, be sure the engine is level and the ignition

switch is in the OFF position (per equipment manufacturers specication).

A. Check Oil Level

To avoid engine damage, it is important to:

• Check oil level before each use and every 5 operating hours when engine is warm.

Check oil level more frequently during engine break-in.

• Keep oil level between “FULL” and “ADD” marks on the oil dipstick.

• Be sure oil dipstick is inserted securely.

Notes

• DO NOT overfill. Doing so may result in oil carry-over to the air cleaner and

equipment and cause malfunction or damage.

• DO NOT allow oil level to fall below the “ADD” mark on oil dipstick. Doing so may

result in equipment malfunction or damage.

B. Filling Oil Sump

1. Be sure engine is level.

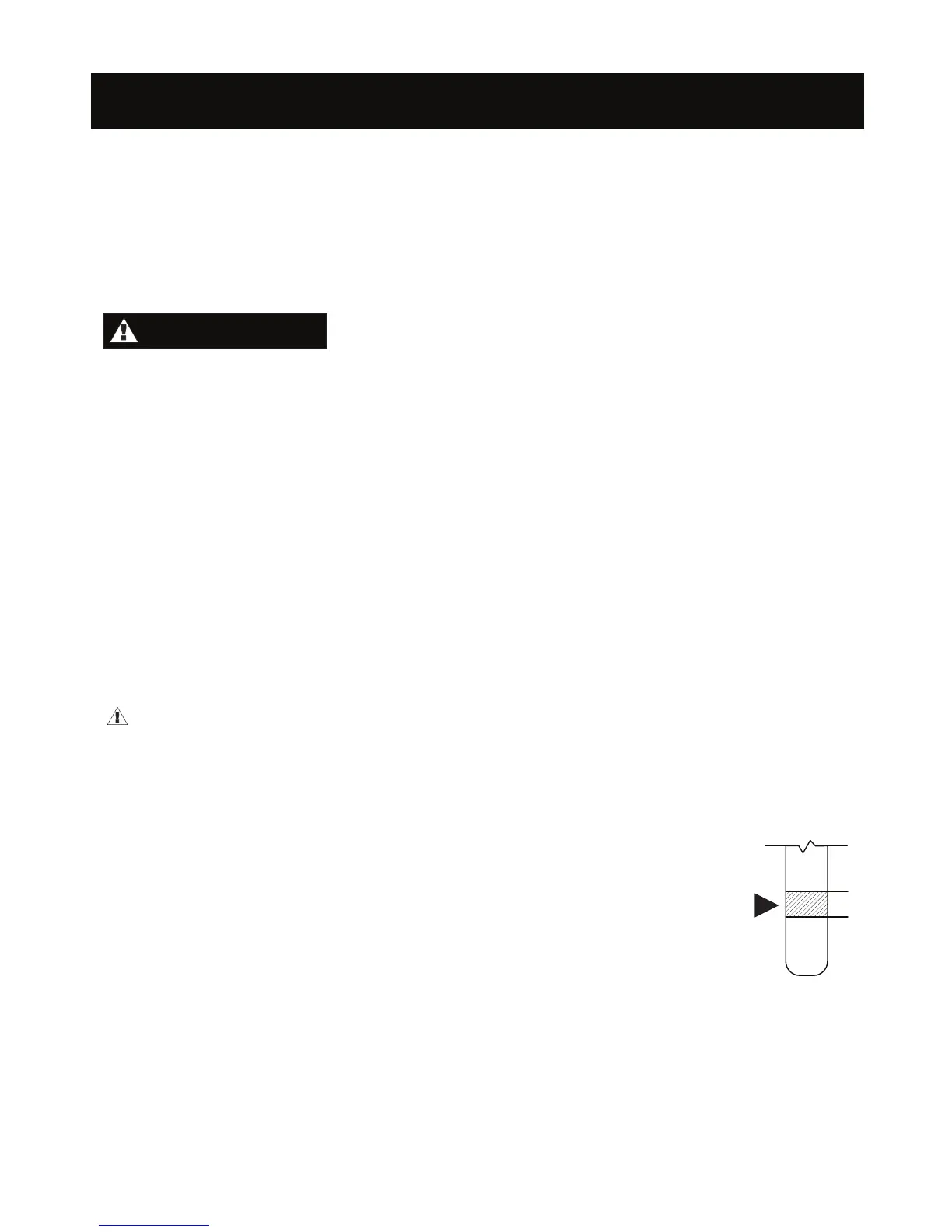

2. Remove oil dipstick from oil ller tube and wipe

dipstick clean. See Figure 2, page 5.

3. Insert dipstick back into oil ller tube securely.

4. Remove oil dipstick from oil ller tube. Note oil level. If oil reading

on dipstick is below “ADD” mark, slowly add oil to reach “FULL” level.

5. Insert oil dipstick back into oil ller tube securely.

6. Wipe away any spilled oil on or around the engine.

FULL

OK

ADD

Fill between

“Full” and “Add”

FIG. 1

Loading...

Loading...