GMV5 DC INVERTER VRF UNITS SERVICE MANUAL

61

There must be a secure distance between pipes. Pipes in different types must be fixed separately.

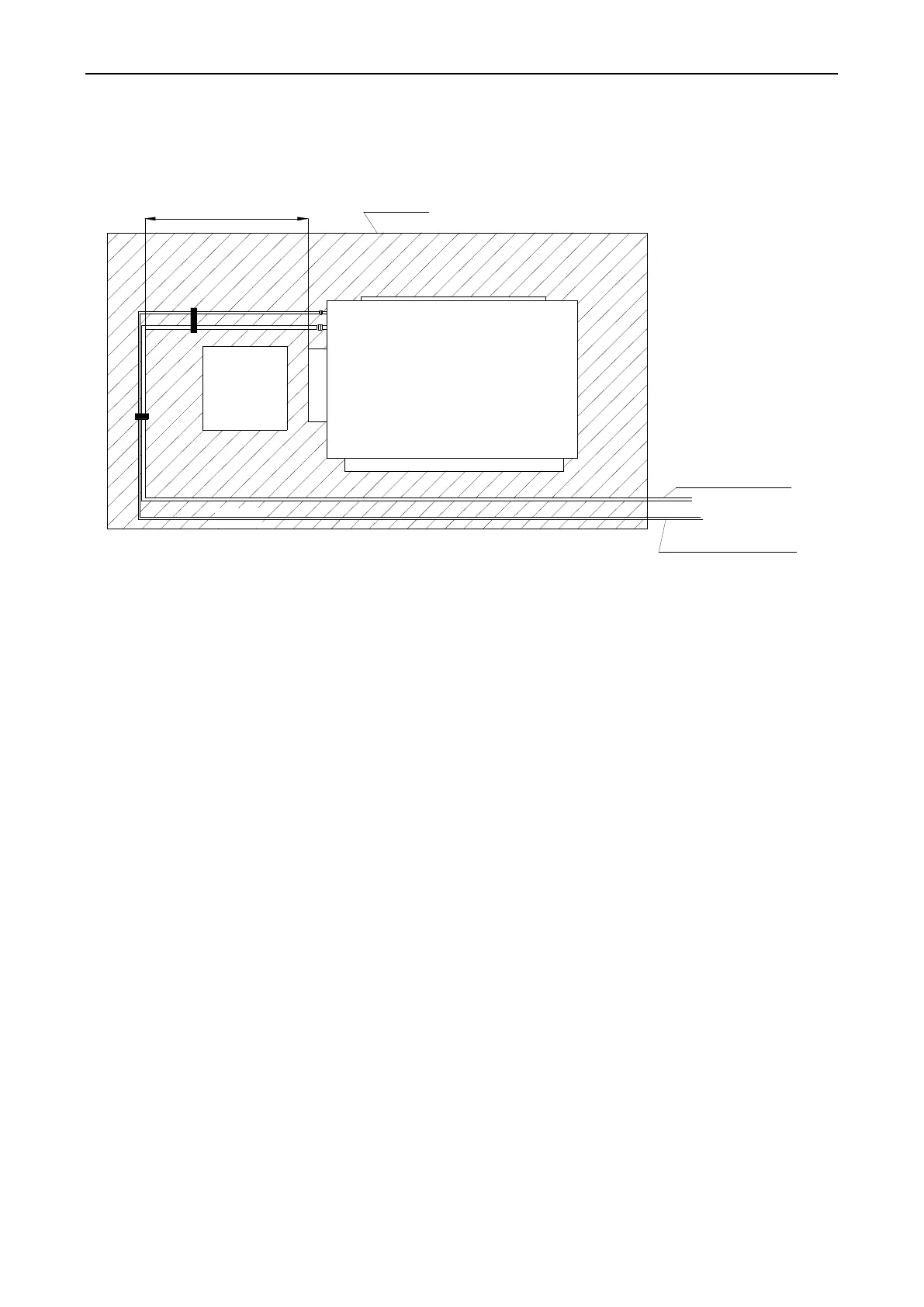

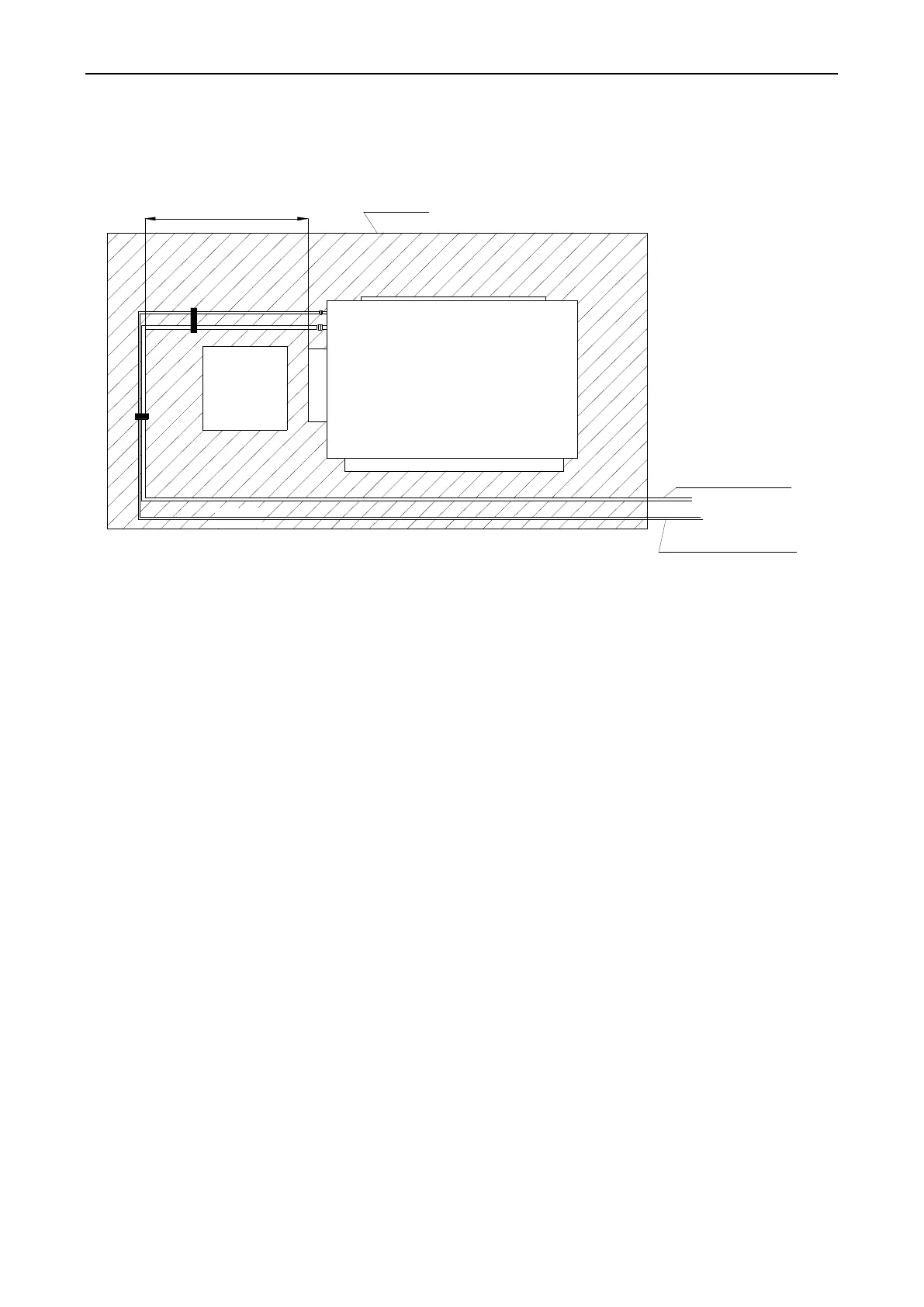

3.8 During refrigerant pipe installation, ensure a distance above 500 mm between the pipe and the

electric box of the unit for maintenance. In a case when the space is not enough, the final piping way

must be determined by the technical personnel.

The distance cannot

be less than 500 mm.

Ceiling

Manhole

Air pipe indoor unit

Gas pipe

Liquid pipe

3.9 Filter and Drier Installation for the ODU

As the piping for the VRF system is complex, it is recommended that a filter is installed for the gas

pipe and a drier is installed for the liquid pipe during construction. This ensures aridity and cleanness of

the piping system and further improves the operation stability of the system.

The procedure is as follows:

First, weld a stop valve with the corresponding caliber to the gas pipe and liquid pipe at the position

relatively close to the ODU and easy for operation.

Second, install a filter (100 mesh/ft2) between the added stop valve outside the gas pipe and the

stop valve of the ODU. Then install a drier filter between the added stop valve outside the liquid pipe and

the stop valve of the ODU.

Lastly, after the test run is complete,

To remove the filter from the gas pipe after starting all IDUs and keeping them running cooling mode

for 24 hours: (1) Power off all units. (2) Turn off the two stop valves of the gas pipe. (3) Remove the filter.

(4) Short connect with a copper pipe with the same caliber and vacuumize the pipe. (5) Open the two

stop valves and keep normal running.

To remove the drier filter from the liquid pipe after starting all IDUs and keeping them running in

heating mode for 24 hours: (1) Power off all units. (2) Turn off the two stop valves of the liquid pipe. (3)

Remove the drier filter. (4) Short connect with a copper pipe with the same caliber and vacuumize the

pipe. (5) Turn on the two stop valves and keep normal running.

Loading...

Loading...