96

Installation and Maintenance

Service Manual

(1) After tightening the screw, pull the power cord slightly to check

if it is rm.

(2) Never cut the power connection wire to prolong or shorten the

distance.

Note:

can't raise

upwards.

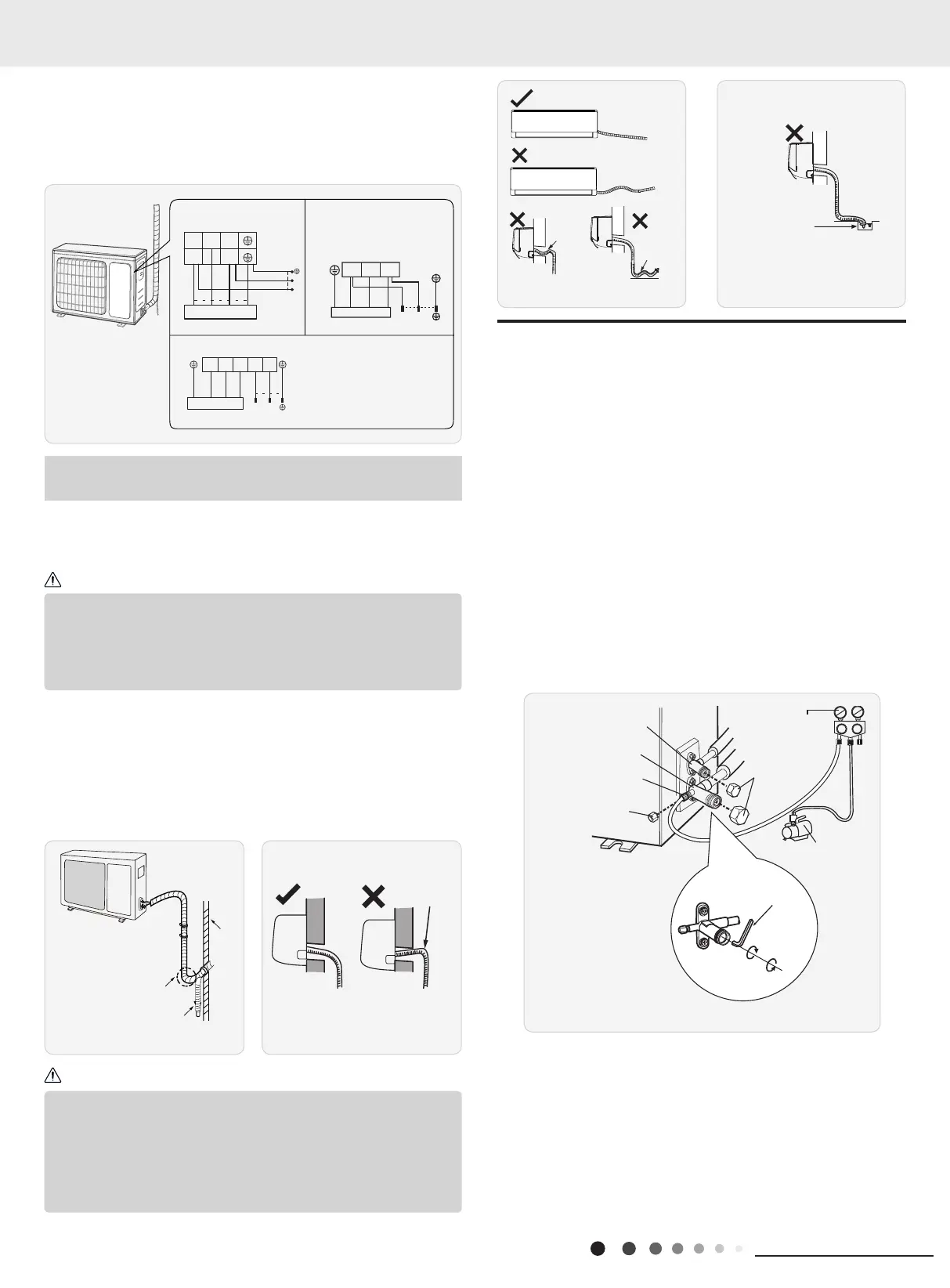

5. Connect Outdoor Electric Wire

(1) Remove the wire clip; connect the power connection wire and

signal control wire (only for cooling and heating unit) to the wiring

terminal according to the color; x them with screws.(As show in

Fig.23)

6. Neaten the Pipes

(1) The pipes should be placed along the wall, bent reasonably and

hidden possibly. Min. semidiameter of bending the pipe is 10cm.

(2) If the outdoor unit is higher than the wall hole, you must set

a U-shaped curve in the pipe before pipe goes into the room, in

order to prevent rain from getting into the room.(As show in Fig.24)

(2) Fix the power connection wire and signal control wire with wire

clip (only for cooling and heating unit).

Fig.23

Fig.24 Fig.25

Indoor unit connection

LN

N(1) 23

L

N

POWER

blue

blue

brown

brown(black)

black

yellow-

green

yellow-green

yellow-

green

N(1)

blue

POWER

2

N

Indoor unit connection

black (black)

L(3)

brown

brown

L

blue

yellow-

green

GWH09AFC-K6DNA2F/O

GWH12AFC-K6DNA2F/O

GWH18AFD-K6DNA2I/O

GWH18ALD-K6DNA1A/O

GWH24ALD-K6DNA1B/O

GWH24AFE-K6DNA2I/O

GWH07QA-K6DNC4A/O

GWH09AGA-K6DNA1A/O

GWH12AGB-K6DNA1A/O

LN

Indoor unit connection

GWH18QD-K6DNA1D/O

GWH24QE-K6DNA1E/O

LN

POWER

N(1)2 3

blue

brown

brown

(black)

blue

yellow-

green

black

yellow-

green

Note: the wiring connect is for reference only,please refer to the

actual one.

U-shaped curve

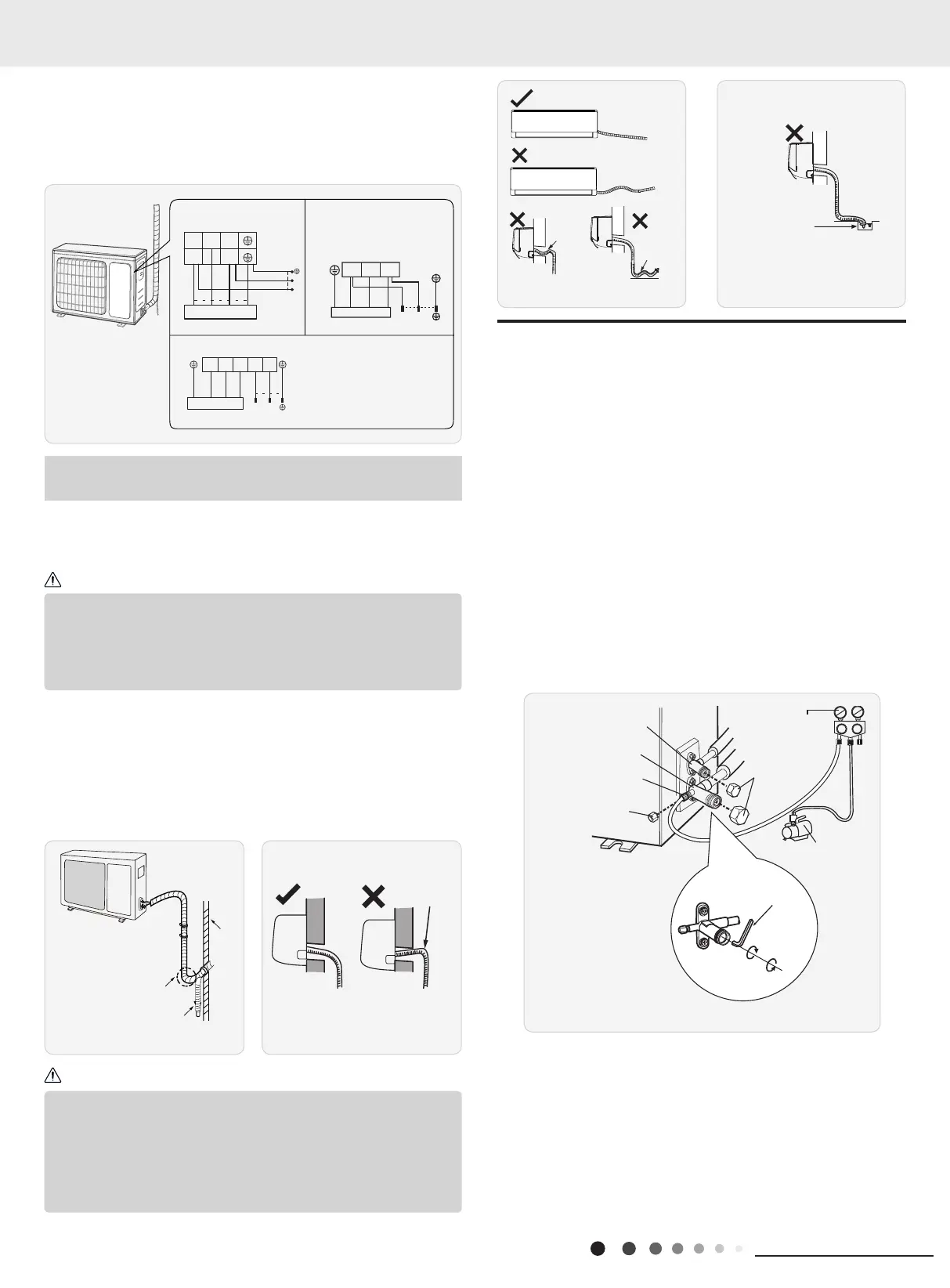

(1) The through-wall height of drain hose shouldnt be higher than

the outlet pipe hole of indoor unit.(As show in Fig.25)

(2) Slant the drain hose slightly downwards. The drain hose cant

be curved, raised and uctuant, etc.(As show in Fig.26)

(3) The water outlet cant be placed in water in order to drain

smoothly.(As show in Fig.27)

Note:

Liquid valve

Gas valve

Refrigerant charging

vent

Nut of refrigerant

Charging vent

Vacuum pump

Piezometer

Valve cap

Lo Hi

Inner hexagon

spanner

Open

Close

The drain hose can't be fluctuant

The drain

hose can't

be fluctuant

The water

outlet can't

The water outlet

can't be placed

in water

1. Use Vacuum Pump

(1) Remove the valve caps on the liquid valve and gas valve and

the nut of refrigerant charging vent.

(2) Connect the charging hose of piezometer to the refrigerant

charging vent of gas valve and then connect the other charging

hose to the vacuum pump.

(3) Open the piezometer completely and operate for 10-15min to

check if the pressure of piezometer remains in -0.1MPa.

(4) Close the vacuum pump and maintain this status for 1-2min

to check if the pressure of piezometer remains in -0.1MPa. If the

pressure decreases, there may be leakage.

(5) Remove the piezometer, open the valve core of liquid valve

and gas valve completely with inner hexagon spanner.

(6) Tighten the screw caps of valves and refrigerant charging

vent.(As show in Fig.28)

8.7 Vacuum Pumping and Leak Detection

Fig.26 Fig.27

Fig.28

2. Leakage Detection

(1) With leakage detector:

Check if there is leakage with leakage detector.

(2) With soap water:

If leakage detector is not available, please use soap water for

leakage detection. Apply soap water at the suspected position and

keep the soap water for more than 3min. If there are air bubbles

coming out of this position, there's a leakage.

Loading...

Loading...