Universal Single Width Fans 17

®

Recommended Bearing Lubrication Schedule

Relubrication Schedule in Months

Standard Grease

Fan

RPM

Bearing Bore (inches)

1/2 -1 1

1

⁄8 - 1

1

⁄2 1

5

⁄8 - 1

7

⁄8 1

15

⁄16 - 2

3

⁄16 2

7

⁄16 - 3

To 250 12 12 12 12 12

500 12 12 11 10 8

750 12 9 8 7 6

1000 12 7 6 5 4

1250 12 6 5 4 3

1500 12 5 4 3 2

2000 12 3 3 2 1

2500 12 2 2 1 0.5

3000 12 2 1 0.5 0.25

3500 12 1 0.5 0.25 x

4000 12 0.5 0.25 x x

5000 12 0.25 x x x

Number

of Shots

4 8 8 10 16

Bearing Lubrication Schedule

Shaft bearings are the most critical moving part of a fan. Therefore, special attention should be given to keeping

the bearings clean and well lubricated. Proper lubrication provides for reduction in friction and wear, transmission

and dissipation of heat, extended bearing life, and prevention of rust.

In order for a lubricant to fulfill these tasks, the proper grease applied at regular intervals is required. See the

recommended bearing lubrication schedule below.

If unusual conditions exist (temperatures below 32°F or above 200°F), moisture or contaminants - more frequent

lubrication is required.

• Lubrication interval is based on 12 hour per day operation

and maximum 160°F housing temperature. For 24 hour per

day operation, the interval should be cut in half.

• Lubricant should be added with the shaft rotating and

until clean grease is seen purging from the bearing. The

lubrication interval may be modified based on the condition

of the purged grease. If bearing is not visible to observe

purged grease, lubricate with number of shots indicated in

chart for bore size.

• For conditions including high temperatures, moisture, dirt

or excessive vibration, consult the factory for a specific

lubrication interval for your application.

• Lubricant should be a high quality lithium complex grease

conforming to NLGI Grade 2. Factory recommends Mobilux

EP-2.

• The use of synthetic lubricants will increase lubrication

intervals by approximately 3 times.

In addition to lubricating the bearings at specified

intervals, set screws in the bearing collars should be

checked for tightness. A bearing collar which has

loosened will cause premature failure of the fan shaft.

Fasteners attaching the bearings to the drive frame

should also be checked.

Wheel and Fastener Maintenance

Wheels require very little attention when exhausting clean air, however, air heavily laden with grease or dirt

will tend to accumulate on the wheel causing unbalance. Wheels exhausting dirty or grease-laden air require

frequent cleaning to assure smooth and safe operation.

All fasteners, including set screws in the bearing collars, should be checked for tightness each time maintenance

checks are performed.

A proper maintenance program will help preserve the performance and reliability designed into the fan.

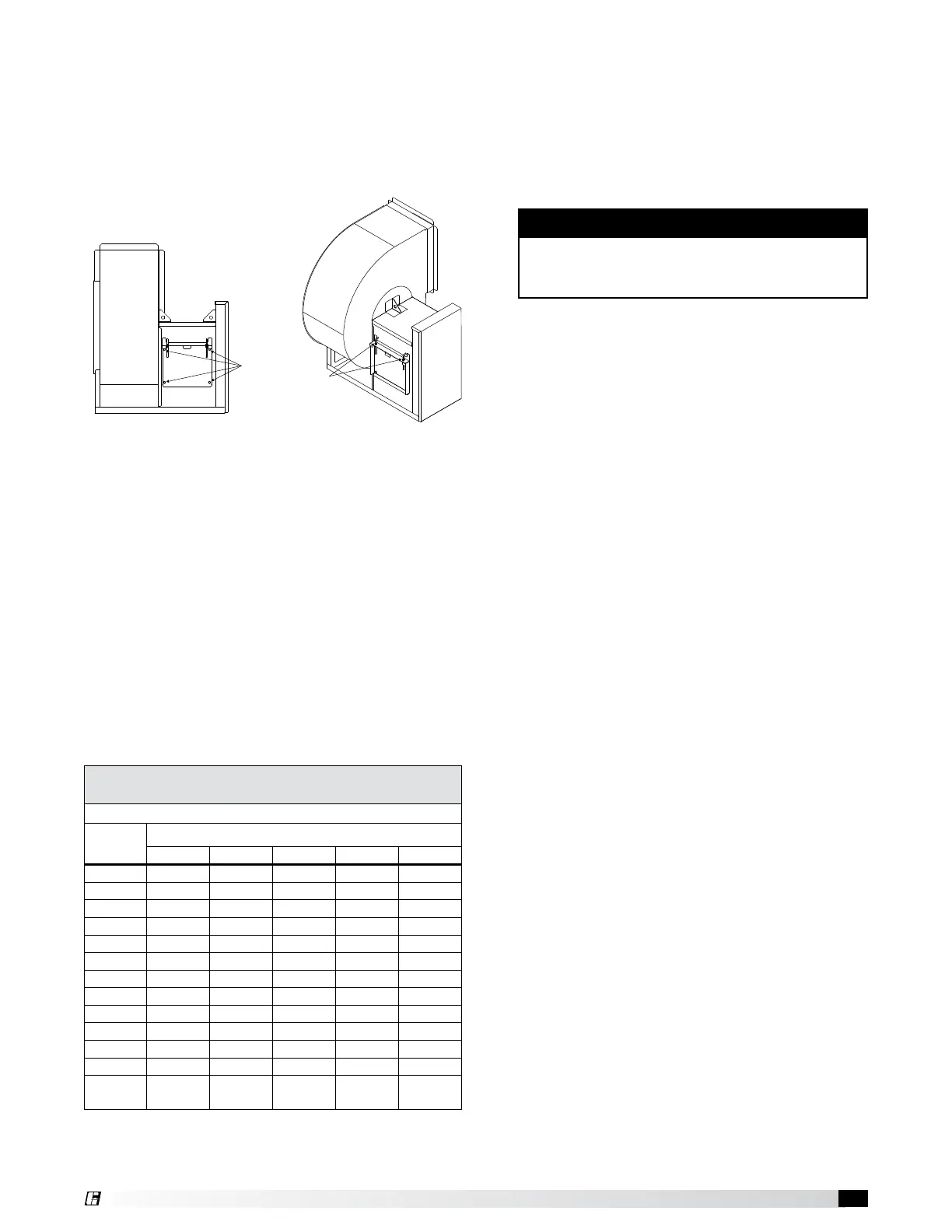

Model USF Series 100, Belt Drive – Belt Adjustment

Belts on the USF series 100 are adjusted from the exterior of the fan. The end cover must be removed so that

the belt(s) can be inspected and checked for proper tension.

1. Loosen, but DO NOT remove the four corner bolts on the adjustment plate.

2. Loosen, then adjust L-bolts on adjustment plate to tighten or loosen belt(s) as needed.

3. Tighten L-adjustment bolts and the four corner bolts to lock motor in place after proper tension is reached.

NOTE

Loosen the corner bolts as minimal as possible

to allow the plate to move, but so the plate has

minimal movement when bolts are re-tightened.

L-Adjustment

Bolts

Corner

Bolts

Loading...

Loading...