Universal Single Width Fans8

The adjustable motor pulley is set at the factory for the fan RPM specified by the customer. Fan RPM can be

increased by closing or decreased by opening the adjustable motor pulley. Multigroove variable pitch pulleys

must be adjusted an equal number of turns open or closed. Any increase in fan speed represents a substantial

increase in load on the motor.

To avoid motor overheating and possible burnout, motor load amperes should always be checked and compared

to nameplate rating when fan speed is increased.

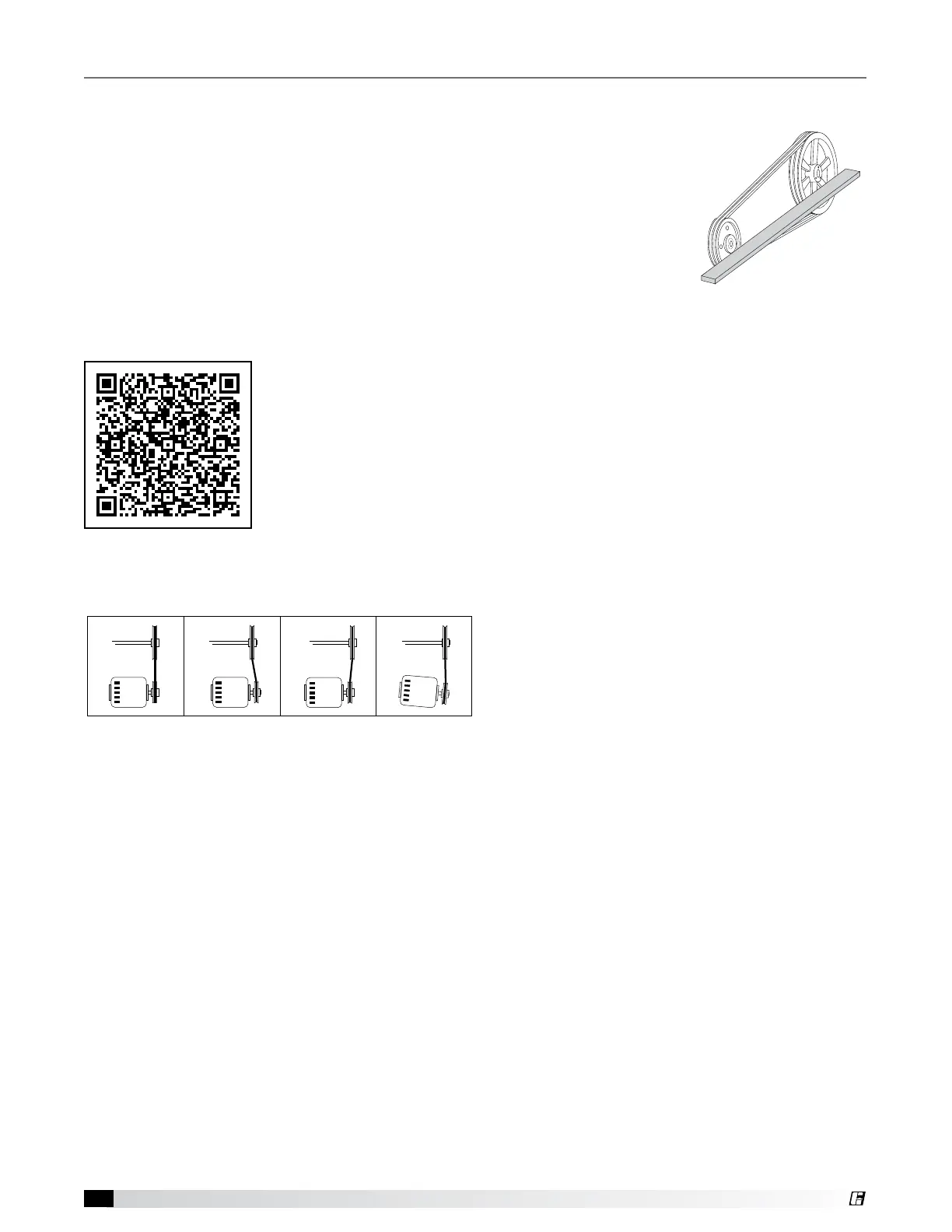

Alignment of Pulleys and Belts

Check pulleys and belts for proper alignment to avoid unnecessary belt wear, noise, vibration and power loss.

Motor and drive shafts must be parallel and pulleys in line as shown in Figure 1.

Do not force belt(s). Forcing the

belt(s) will break the cords and

cause belt failure

Deflection =

Belt Span

64

Slack

Side

Belt

Span

CORRECT WRONG

WRONG WRONG

CORRECT WRONG WRONG WRONG

Figure 1

V-Belt Drives

V-Belt Drive Installation

1. Remove the protective coating from the end of the fan shaft using mineral spirits or another

similar solvent. Check to ensure that the shaft is free of nicks and burrs.

2. Slide sheaves on shafts. Do not drive sheaves on as this may result in bearing damage.

3. Align fan and motor sheaves with a straight edge or string and tighten.

4. Place belts over sheaves. Do not pry or force belts, as this could result in damage

to the cords in the belts.

5. Adjust the tension until the belts appear snug. Run the unit for a few minutes and

allow the belts to “set” properly.

6. With the fan off and disconnect locked out, adjust the belt tension by moving the

motor pivot plate. When in operation, the tight side of the belts should be in

a straight line from sheave to sheave with a slight bow on the slack side.

Aligning Sheaves with

a Straight Edge

Measuring Belt Tension (FA/127-11)

www.greenheck.com/resources/library/application-articles

Loading...

Loading...