Universal Single Width Fans 7

®

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

POOR

POOR

GOOD

POORGOOD

Three fan wheel diameters

GOOD

Three fan wheel diameters

3/4 to one

fan

inlet

diameter

3/4 to

one fan

wheel

diameter

One fan

diameter

3/4 to

one fan

wheel

diameter

SYSTEM EFFECT FACTORS CURVES

STATIC PRESSURE LOSS

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 5 10 15 20 25 30 35 40 45

FPM X 100

OUTLET VELOCITY

CURVE 1

CURVE 2

CURVE 3

CURVE 4

3/4 to one

fan

inlet

diameter

Non-Ducted Installations

Inlet Clearance - Installation of a fan with an

open inlet too close to a wall or bulkhead will cause

reduced fan performance. It is desirable to have

a minimum of three-fourths of a wheel diameter

between the fan inlet and the wall.

Free Discharge - Free or abrupt discharge into a plenum results

in a reduction in fan performance. The effect of discharge static

regain is not realized.

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Turning

Vanes

Turning

Vanes

POOR

POOR

GOOD

POORGOOD

Length of Straight Duct

GOOD

1 Fan

Wheel

Diameter

3/4 to one

fan

wheel

diameter

3/4 to one

fan

wheel

diameter

3/4 to one

fan

wheel

diameter

3/4 to one

fan

wheel

diameter

One fan

diameter

3/4 to one

fan

wheel

diameter

SYSTEM EFFECT FACTORS CURVES

STATIC PRESSURE LOSS

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 5 10 15 20 25 30 35 40 45

FPM X 100

OUTLET VELOCITY

CURVE 1

CURVE 2

CURVE 3

CURVE 4

Single Fan Installation

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

POOR

GOOD

POORGOOD

Three fan wheel diameters

GOOD

Three fan wheel diameters

3/4 to one

fan

inlet

diameter

3/4 to

one fan

wheel

diameter

One fan

diameter

3/4 to

one fan

wheel

diameter

SYSTEM EFFECT FACTORS CURVES

STATIC PRESSURE LOSS

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 5 10 15 20 25 30 35 40 45

FPM X 100

OUTLET VELOCITY

CURVE 1

CURVE 2

CURVE 3

CURVE 4

3/4 to one

fan

inlet

diameter

Check local codes for proper disposal of drain water

which has been in contact with the exhaust air.

Fans used for grease exhaust need to be equipped

with a separate grease collector.

Inlet Spin - Inlet spin is a frequent cause of reduced fan

performance. The change in fan performance is a function

of the intensity of spin and not easily defined. The best

solution is proper duct design and airflow patterns.

Turning vanes reduce the effects of inlet spin.

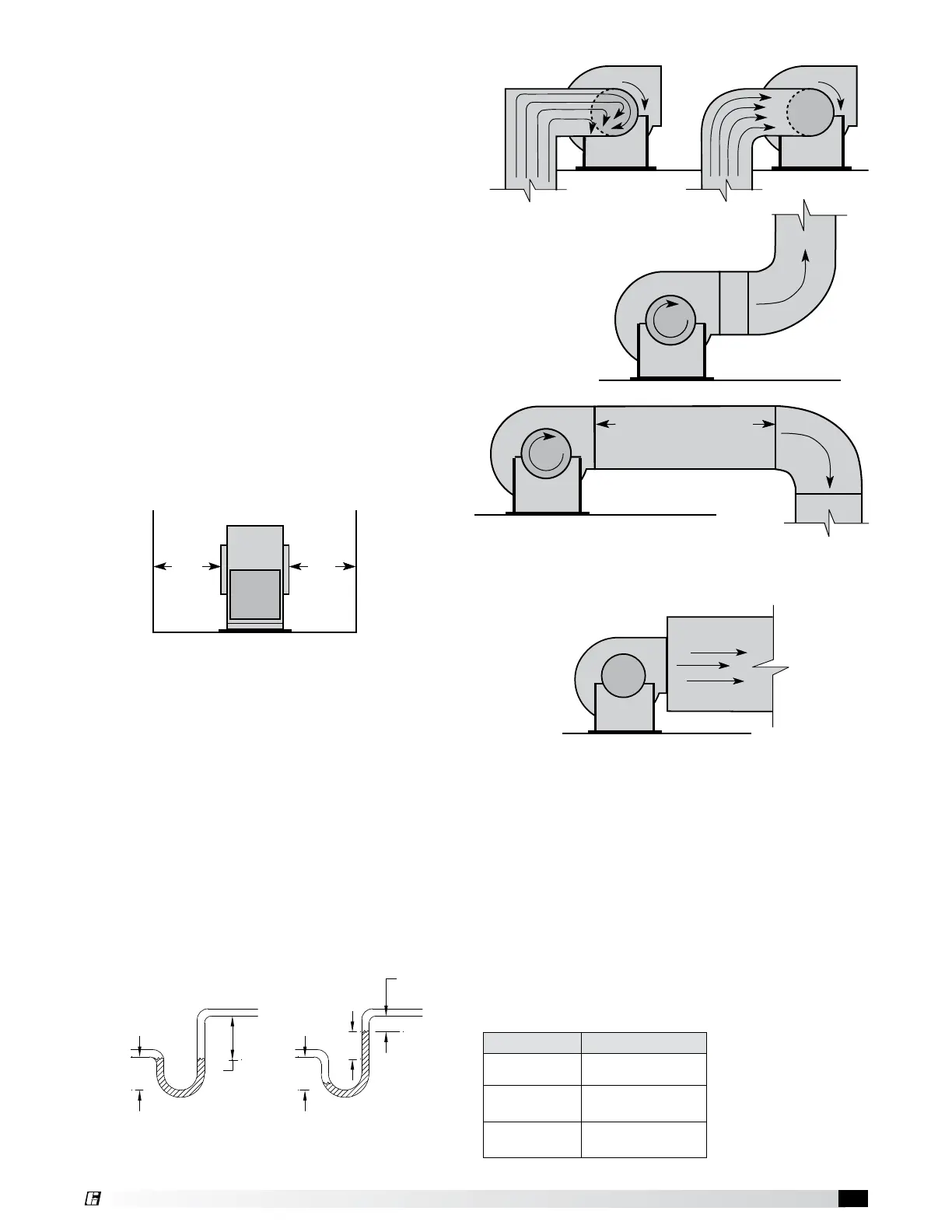

Series Drain Options

100 Drain only *

300

No drain

Drain with plug

500

No drain

Drain with plug

* 1 inch (25.4 mm) non-threaded drain hole

Fan Drainage Piping and Trap Detail (by others)

Fans may have been supplied with an optional drain. Drains are located at the underside of the scroll housing.

The drain may need to be connected to a drainage system to ensure proper disposal of any water or condensate

that may occur.

• Drain connections with a plug are 1 inch (25.4mm) MNPT.

• Installed piping to have a downward angle to allow for drainage.

• Fill traps to recommended level before start-up.

Note: A conservative method of trap design is to set N = total static pressure.

Positive Pressure Trap

RECOMMENDED DRAIN TRAP DESIGN

(TRAP BY OTHERS)

FAN BYPASS

AIR PLENUM

ENERGY RECOVERY

PLENUM

SUBFLOOR

SUBFLOOR

1.25 NPT

.75 NPT

*BASED ON STANDARD

VEKTOR ERS CURB HEIGHTS

*

*

ROOF

CURB

ROOF

CURB

P.O.BOX 410 SCHOFIELD, WISCONSIN 54476-0410

TITLE

DRAWN BY

ECO

B

ENG. REF.

DATE

SUPERSEDES

SCALE

CAD DRAWING NO.

FAUST

06/29/2009

1/8

VK-ERS

N = Negative fan pressure (inches W.C.)

H = N - 0.5 inches minimum

Note: A conservation method of trap design is to set

N = TSP and P = TSP (TSP = Total Static Pressure)

H/2

H/2

H

1.25 inch minimum

N

FAN ON

FAN OFF

NEGATIVE PRESSURE TRAP

14.750

14.000

NOTE: INSULATION OR OTHER MEANS

OF FREEZE PROTECTION MAY BE

REQUIRED IN CERTAIN CLIMATES

RECOMMENDED DRAIN TRAP DESIGN

(TRAP BY OTHERS)

N = Negative fan pressure (inches W.C.)

H = N - 0.5 inches minimum

NOTE: A conservative method of trap design is to set

N = Total Static Pressure and P = Total Static Pressure

H/2 H/2

H

1.25 inch

minimum

N

FAN ONFAN OFF

Connect

this end

to fan drain.

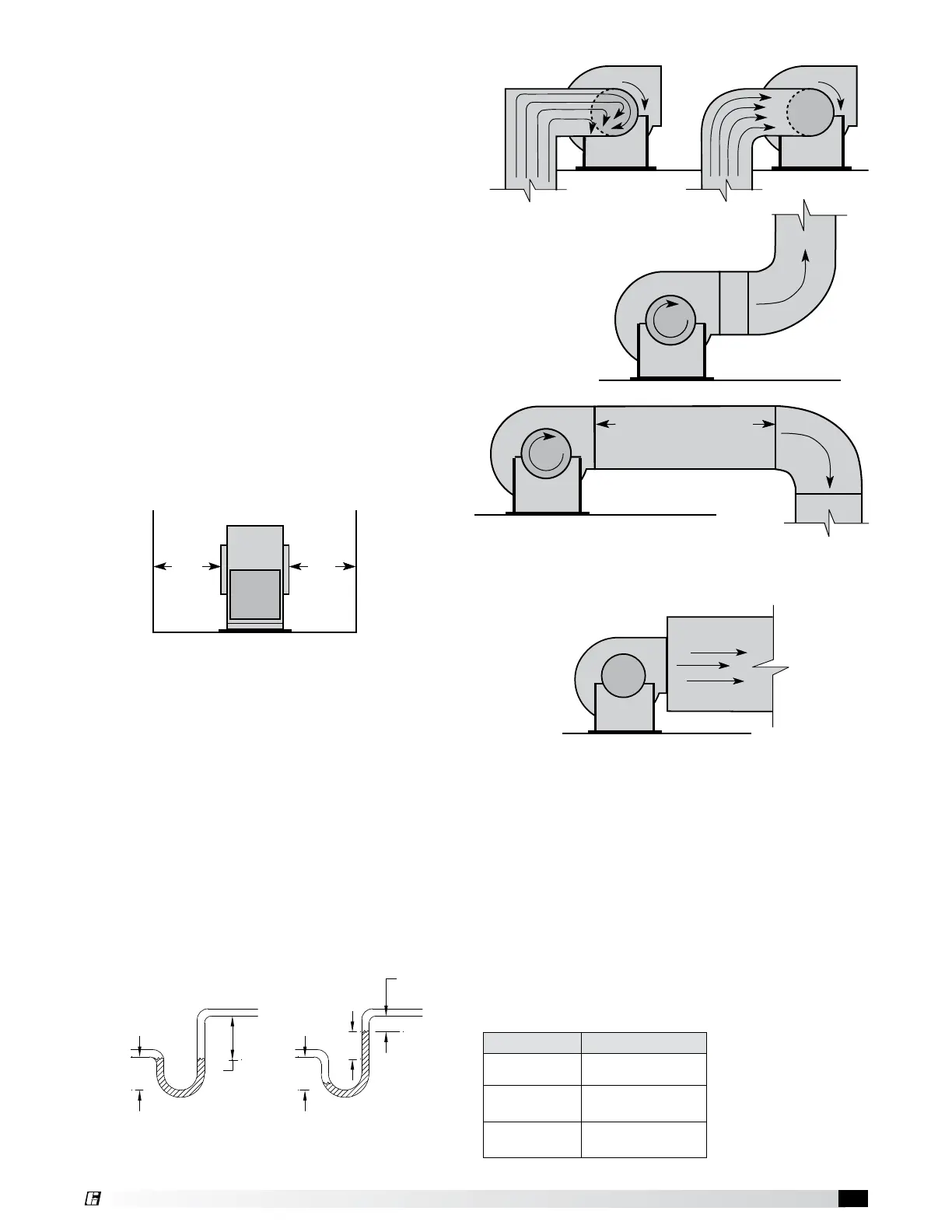

Ducted Outlet Installations

Discharge Duct Turns - Duct turns located near the fan discharge should

always be in the direction of the fan rotation.

Fan performance is reduced when duct turns are made immediately off the

fan discharge. To achieve cataloged fan performance there should be at

least three equivalent duct diameters of straight ductwork between the fan

discharge and any duct turns.

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

POOR

POOR

GOOD

POORGOOD

Three fan wheel diameters

GOOD

Three fan wheel diameters

3/4 to one

fan

inlet

diameter

3/4 to

one fan

wheel

diameter

One fan

diameter

3/4 to

one fan

wheel

diameter

SYSTEM EFFECT FACTORS CURVES

STATIC PRESSURE LOSS

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 5 10 15 20 25 30 35 40 45

FPM X 100

OUTLET VELOCITY

CURVE 1

CURVE 2

CURVE 3

CURVE 4

3/4 to one

fan

inlet

diameter

Loading...

Loading...