Universal Single Width Fans6

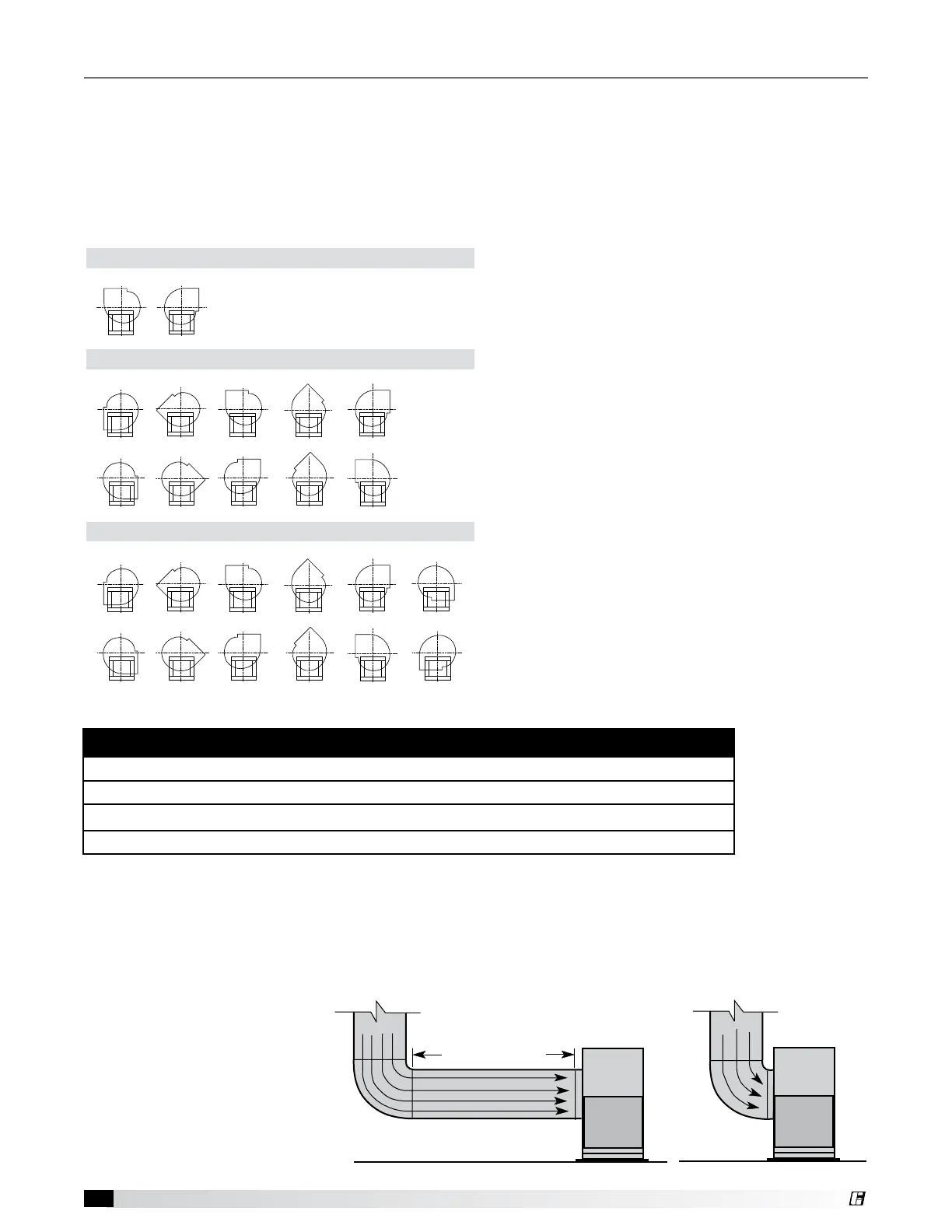

Ducted Inlet Installations

Inlet Duct Turns - Installation

of a duct turn or elbow too

close to the fan inlet reduces

fan performance because air

is loaded unevenly into the

fan wheel. To achieve full fan

performance, there should be at

least three fan wheel diameters

between the turn or elbow and

the fan inlet.

Move the fan to the desired location. Check and tighten fasteners throughout the unit and then fasten securely

through mounting holes provided in the base angles. The unit must be set level (shimming may be necessary).

Flexible duct connections and vibration isolators should be used where noise is a factor.

The motor voltage and ampere rating must be checked for compatibility with the electrical supply prior to

final electrical connection. Supply wiring to the fan must be properly fused, and conform to local and national

electrical codes.

Series 300

Series 500

CW BH

CCW BH

CW BAU

CCW BAU

CW UB

CCW UB

CCW TH

CW TH

CW DB

CCW DB

CW TAU

CCW TAU

CW BH

CCW BH

CW BAU

CCW BAU

CW UB

CCW UB

CCW TH

CW TH

CW TAU

CCW TAU

XUEF-300 and XUEF-400

CW BH

CCW BH

CW BAU

CCW BAU

CW UB

CCW UB

CCW TH

CW TH

CW TAU

CCW TAU

VUSF-300 and VUSF-400

VCSW

CW BH

CCW BH

CW BAU

CCW BAU

CW UB

CCW UB

CCW TH

CW TH

CW DB

CCW DB

CW TAU

CCW TAU

CW BH

CCW BH

CW BAU

CCW BAU

CW UB

CCW UB

CCW TH

CW TH

CW TAU

CCW TAU

Series 100

CW UB CW TH

VUSFD-100 and VUSF-100

CW UB CW TH

XUEFD-100 and XUEF-100

CW UB CW TH

Discharge Positions

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

POOR

POOR

GOOD

POOR

GOOD

Three fan wheel diameters

GOOD

Three fan wheel diameters

3/4 to one

fan

inlet

diameter

3/4 to

one fan

wheel

diameter

One fan

diameter

3/4 to

one fan

wheel

diameter

SYSTEM EFFECT FACTORS CURVES

STATIC PRESSURE LOSS

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 5 10 15 20 25 30 35 40 45

FPM X 100

OUTLET VELOCITY

CURVE 1

CURVE 2

CURVE 3

CURVE 4

3/4 to one

fan

inlet

diameter

Installation

The discharge is factory set as specified by customer

order, however, certain sizes can be rotated to other

discharge positions in the field, if necessary. If rotating

the fan housing, accommodations may need to be

made for the fan to drain properly.

USF Series 100 - Rotatable housings are standard.

Removal of the housing bolts, inlet cone and wheel

allows the discharge to be rotated to the clockwise

positions shown to the left. For models with EC

motors, the motor nuts on the inside of the scroll

will also need to be removed. Fan rotation is always

specified from the drive side of the housing.

USF Series 300 - Rotatable housings are standard

on sizes 49 and less. Removal of the housing bolts,

inlet cone and wheel allows the discharge to be

rotated to the positions shown to the left. Fan rotation

is always specified from the drive side of the housing.

USF Series 500 - Rotatable housings are standard

on sizes 30 and less, arrangements 1, 9 and 10, and

Class 0, I and II. Sizes 33-73, as well as fan classes III

and IV are not field rotatable. Removal of the housing

bolts, inlet cone and wheel allows the discharge to

be rotated to the positions shown to the left. For

downblast (DB) discharge position, a portion of the

frame angle must be removed. Fan rotation is always

specified from the drive side of the housing.

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

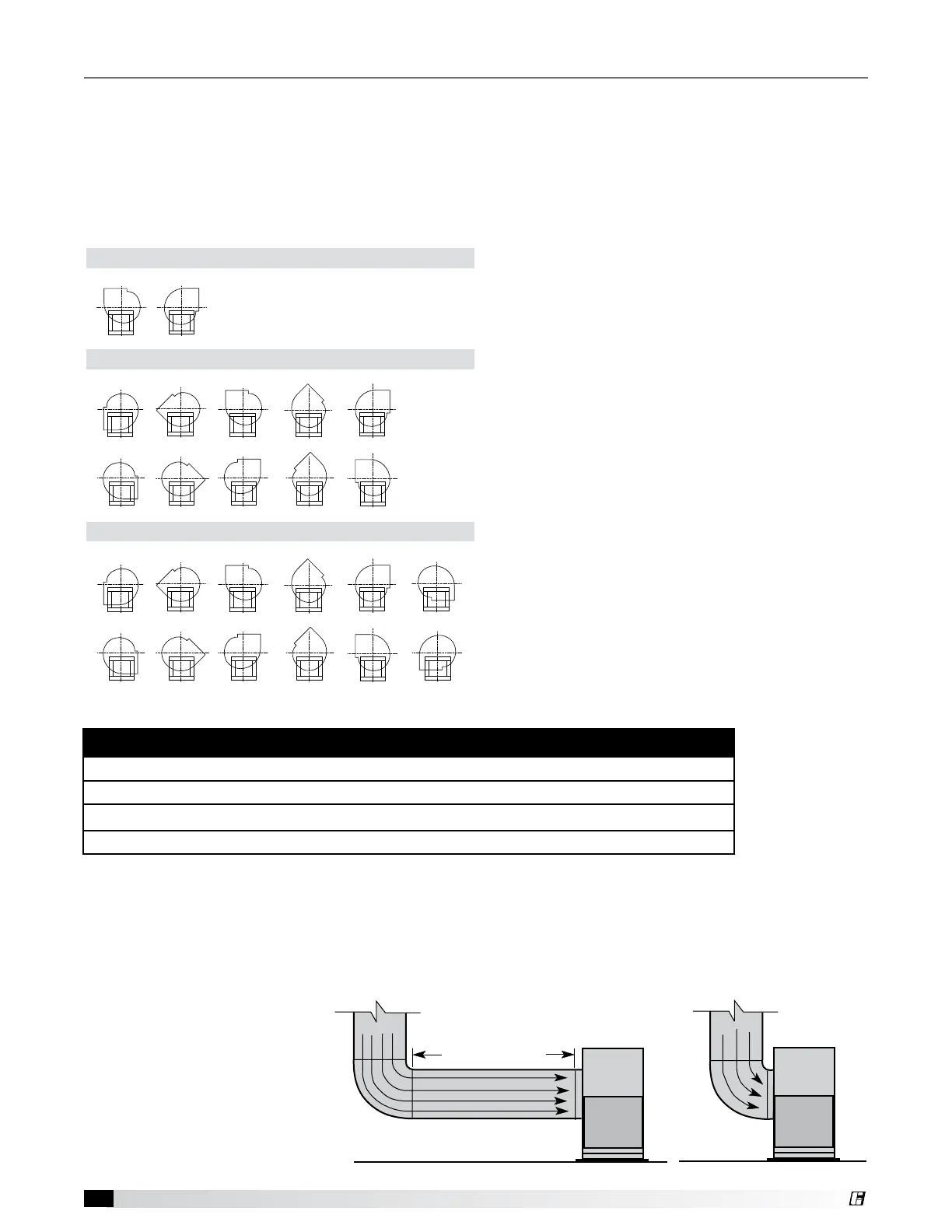

POOR

POOR

GOOD

POOR

GOOD

Three fan wheel diameters

GOOD

Three fan wheel diameters

3/4 to one

fan

inlet

diameter

3/4 to

one fan

wheel

diameter

One fan

diameter

3/4 to

one fan

wheel

diameter

SYSTEM EFFECT FACTORS CURVES

STATIC PRESSURE LOSS

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 5 10 15 20 25 30 35 40 45

FPM X 100

OUTLET VELOCITY

CURVE 1

CURVE 2

CURVE 3

CURVE 4

3/4 to one

fan

inlet

diameter

NOTE

Existing holes will need to be plugged with self-threading fasteners.

Some field housing rotations will require drilling into the fan housing.

All grease fan applications will require the relocation of access door and drain connection.

Trim balance is recommended on the USF series 500.

Installations with inlet or discharge configurations that deviate from this manual may result in reduced fan

performance. Restricted or unstable flow at the fan inlet can cause pre-rotation of incoming air or uneven loading

of the fan wheel yielding large system losses and increased sound levels. Free discharge or turbulent flow in the

discharge ductwork will also result in system effect losses. Refer to the following diagrams for the most efficient

installation conditions.

Loading...

Loading...