40

MAINTENANCE

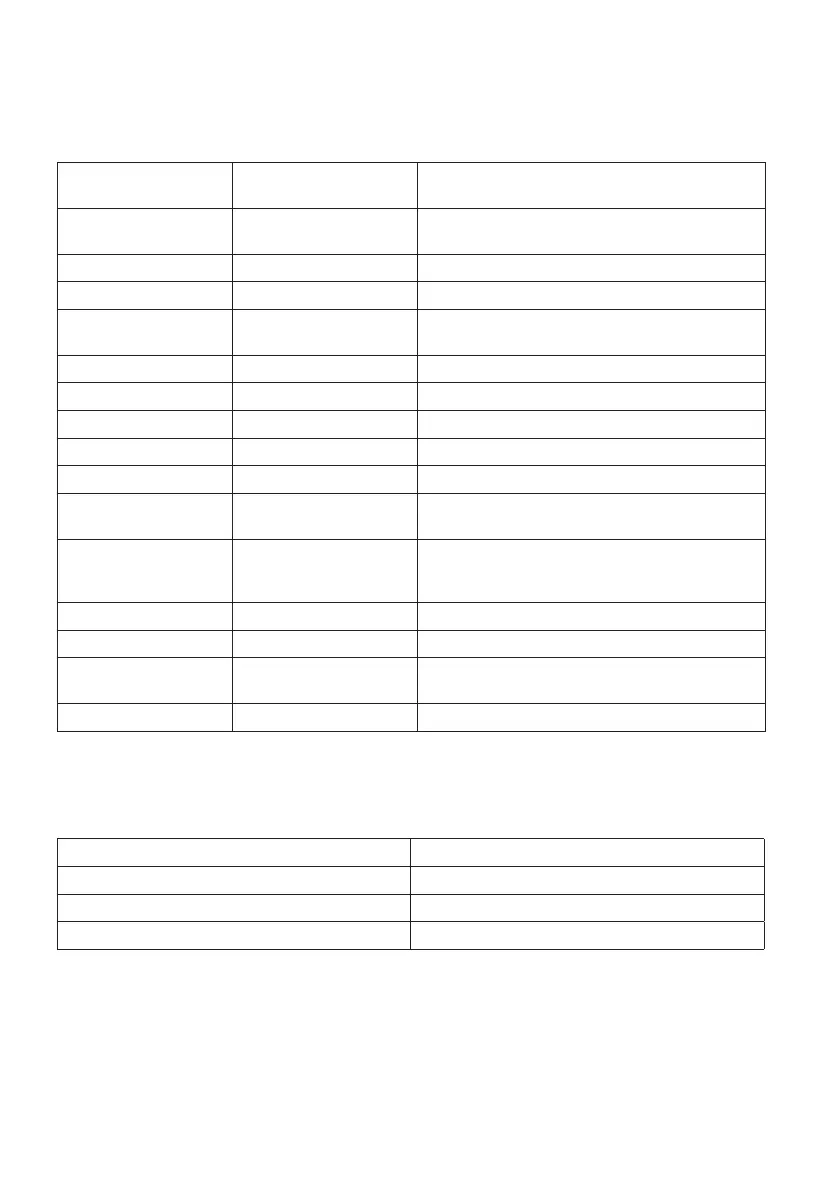

Periodic Maintenance Chart

Perform all services at whichever maintenance interval is reached rst.

Item Maintenance Interval

(whichever comes rst)

Remarks

Headlamp/tail lamp Daily Check operation; apply dielectric grease if

replacing

Brake pad wear Monthly Inspect periodically

Front gear case oil 1 M Perform a break-in oil level check

Main gear case oil

(Transaxle)

1 M Perform a break-in oil level check

General lubrication 3 M Lubricate all ttings, pivots, cables, etc.

Steering 6 M Lubricate

Front Suspension 6 M Lubricate

Rear Suspension 6 M Lubricate

Front gear case oil 12 M Perform a break-in oil level check

Main gear case oil

(Transaxle)

12 M Perform a break-in oil level check

Wiring 12 M Inspect for wear, routing, security; apply

dielectric grease to connectors subjected to

water, mud, etc.

Front wheel bearings 12 M Inspect; replace as needed

Brake uid 24 M Change every two years

Toe adjustment - Inspect periodically; adjust when parts are

replaced

Headlight aim - Adjust as needed

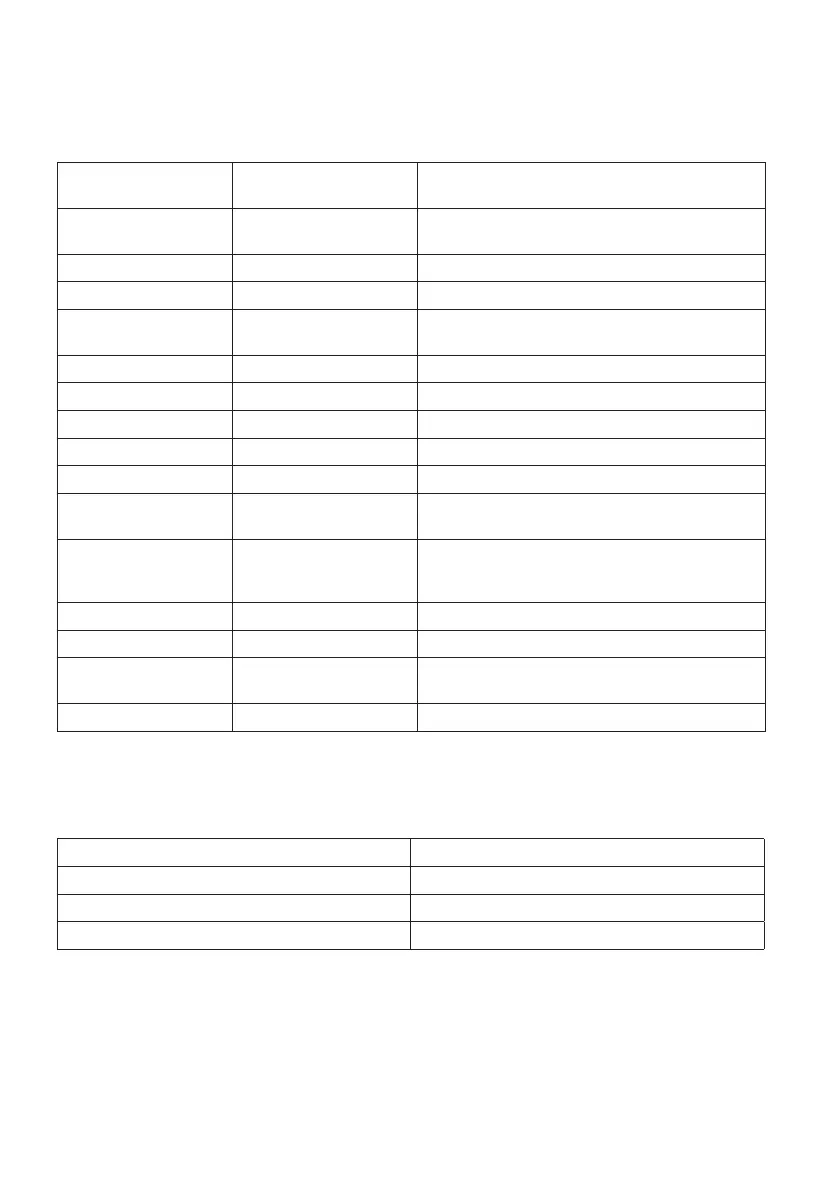

Lubrication Recommendations

Check and lubricate all components at the intervals outlined in the Periodic Maintenance Chart, or

more often under severe use, such as wet or dusty conditions.

Items not listed in the chart should be lubricated at the general lubrication interval.

Item Lube

Brake Fluid DOT 4 Brake Fluid

Main Gear case Oil (Transaxle) SAE80 API GL-4 Hypoid gear oil

Front Gear case Oil SAE80 API GL-5 Hypoid gear oil

Loading...

Loading...