13

Fire Shuer Mechanism

RELEASE ARM FUSIBLE LINKAGE TYPES

There are three basic forms of fusible linkages, heat, voltage, and heat and voltage. These systems may be connected in

series with a cable.

FUSIBLE LINKAGE CONNECTION

The fusible linkage should be connected in series with a spring so that it engages the release arm. The end of the linkage not

connected to the release arm should be fastened to a secure xed point. The linkage must be arranged so that the force

provided to engage the release arm is in a direcon close to parallel to the axis of the output sha.

RELEASE ARM SPRING TENSION

When the release arm is in the engaged posion, the spring should be stretched to be at least 250mm in length.

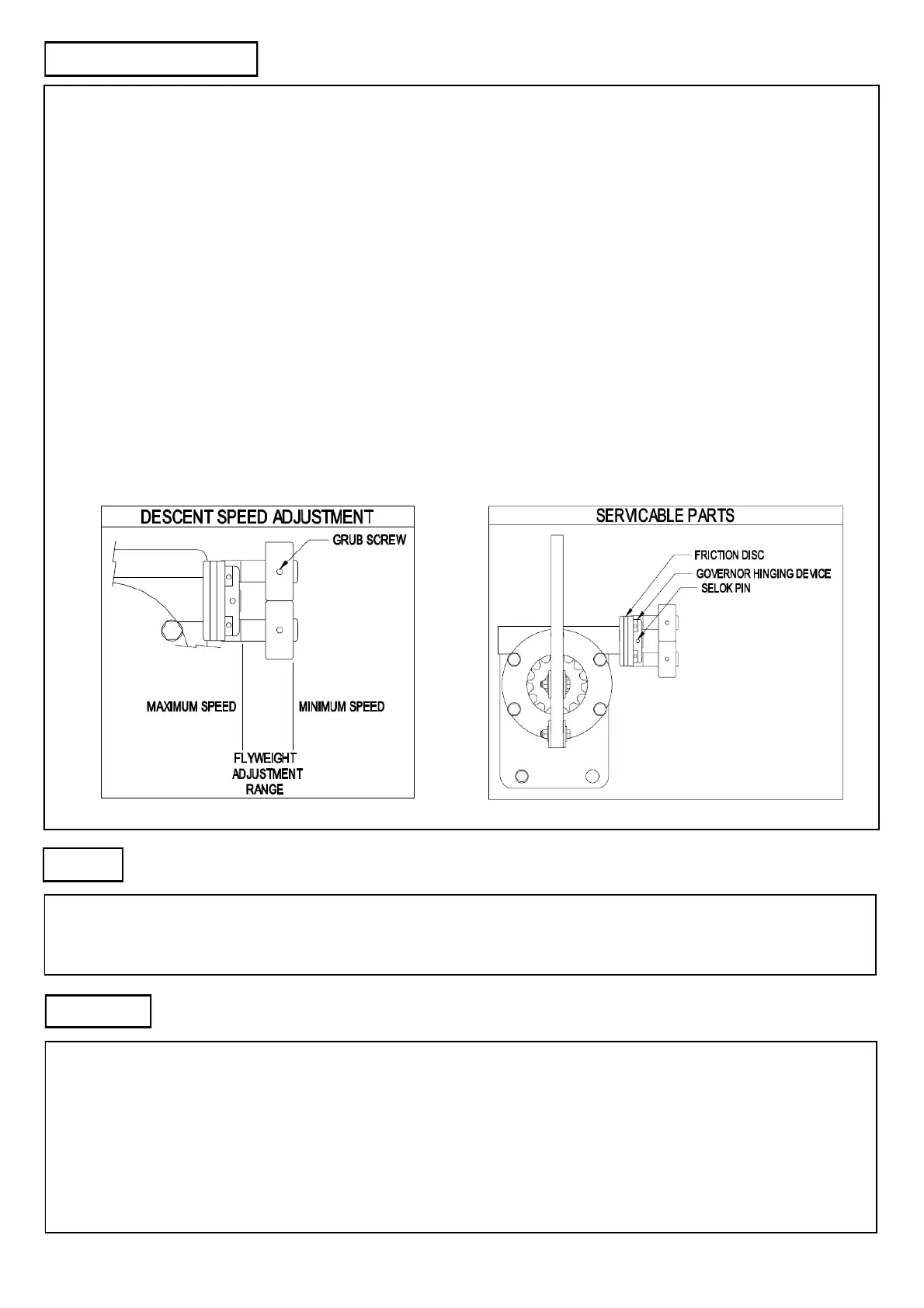

ADJUSTING THE CONTROLLED DESCENT SPEED

The speed at which the shuer falls during controlled descent can be adjusted by moving the governor yweights. If the

yweights are at their outermost points on their shas, descent speed will be at its lowest. If they are on their innermost

points the descent speed will be at its highest. To move the yweights, loosen their grub screws with an allen key and slide

them into the desired posion on their shas. Tighten the grub screws with the allen key.

SETUP AND ADJUSTMENT

To test the system, engage the release arm and li the shuer 500mm with the hand chain. Then disengage the release arm.

The shuer should fall steadily to the ground.

TESTING

OPERATION

If the operator is ed to the shuer and has a spring assisted fusible link causing the release arm to engage or be waing to

engage, it is ready for operaon. The shuer may now be operated manually or electrically.

If the fusible link breaks due to re or re alarm signal, the shuer will undergo controlled descent to the ground. The release

arm is now disengaged.

To operate the shuer aer controlled descent, the release arm must be re-engaged with a new fusible link.

Loading...

Loading...