5

PLANNING

Idenfy the type and dimensions of your commercial door. A survey of the applicaon is recommended to see if any of the

requirements below are not applicable with your installaon.

Based on “standard shuer”:

The shuer is correctly spring balanced

The shuer has ≤ 1.0mm x ≥ 100mm slats

The shuer has no wind-locks

A ≥4:1 sprocket rao is used

If any condions above are not met, some consideraon should be given to increasing the sprocket rao, or opener size. The

opener should be installed on the correct side of the commercial door. Consider an In-board mounng kit

(P.No IBMK) if there is insucient side room. Select the side that meets the requirements listed below.

Must have minimum distance of 15mm between mounng plate and door drum sprocket

Must have minimum distance of 200mm between limit housing and imposing structure

Must have minimum clearance of 200mm from the terminal box

Before installing the opener, check that the commercial door is in good mechanical condion, correctly balanced and open

& closes properly.

BOTTOM RAIL WEIGHT AND/OR REVERSE SPRINGING

To provide the shuer with a greater inial closing force, parcularly when fully open, the boom rail should be made heavier.

This can be achieved by aaching approximately 5kg of steel at bar to the upper side of the boom rail. An alternave or

addional method to ensure the shuer will descend when released is to slightly reverse spring the shuer at its fully open

posion. This will give the shuer a bias towards closing when it is in its fully open posion.

NOTE: The shuer must have radial ball or roller bearings on the shuer axle.

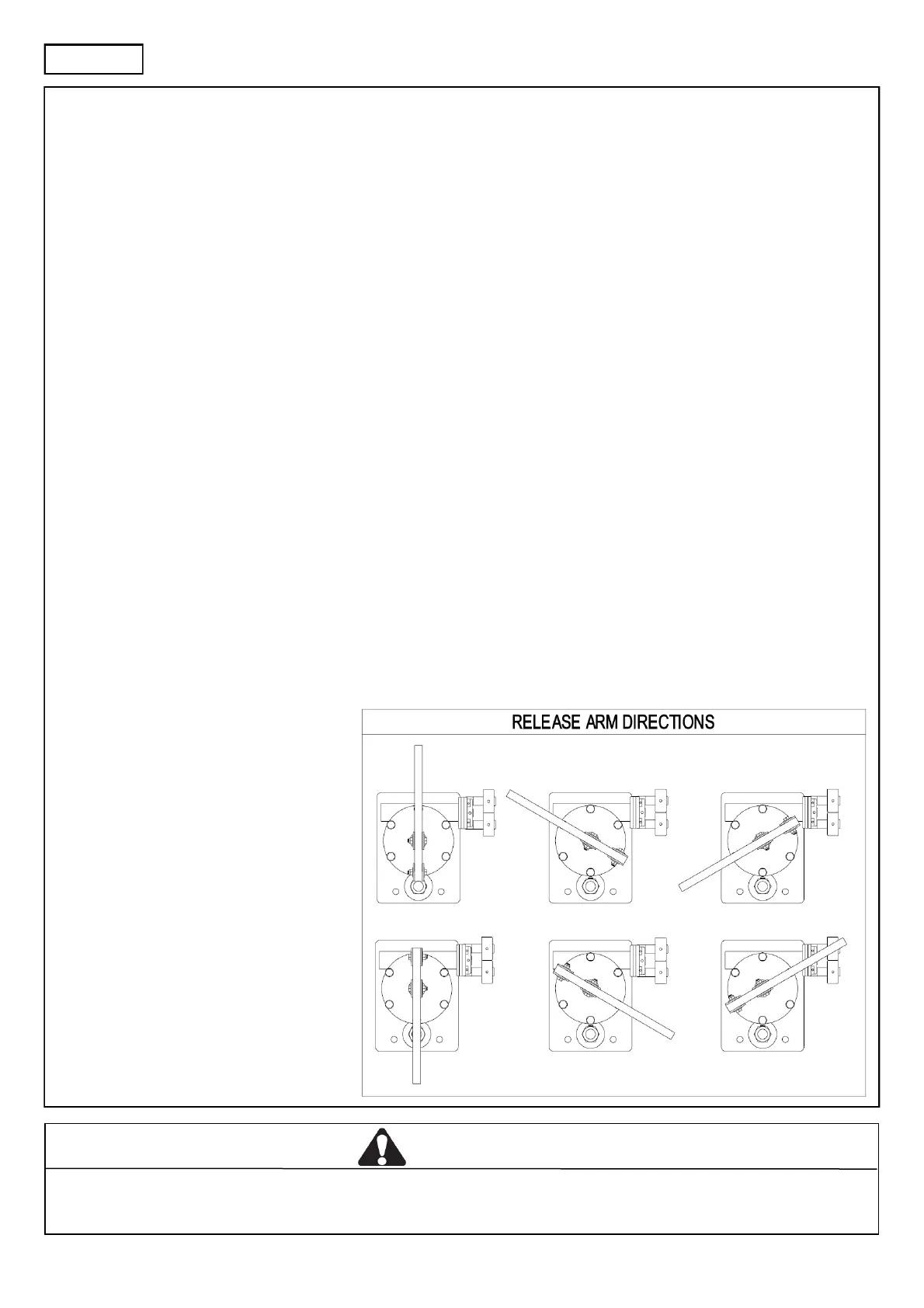

THE RELEASE ARM

The release arm may point in one of the six

direcons allowed by the six bolts on the

plate upon which it is mounted. This is to

allow the fusible linkage to be aached in

the arrangement most convenient to you.

To change the direcon of the arm, remove

the bolt that aaches the boom end of the

arm to the u-bracket. Tilt the arm about the

u-bracket that is connected to the output

sha this will allow access to the boom u-

bracket. The xed u-bracket may be

removed using a spanner on its outside.

Remove the bolt from the plate in the

posion that you wish to t the u-bracket,

screw the u-bracket into this hole. Fit the

spare bolt to the hole where the u-bracket

was. Ret the arm into the u-bracket using

the nut, bolt and washers that were

previously removed.

CAUTION

The roller shuer guides must be ed with mechanical stops that prevent the boom rail from passing through in the opening

direcon. The opener should stall if driving into the mechanical stops.

Loading...

Loading...