AC3OperaonandMaintenance

Pumping Units

Installaon

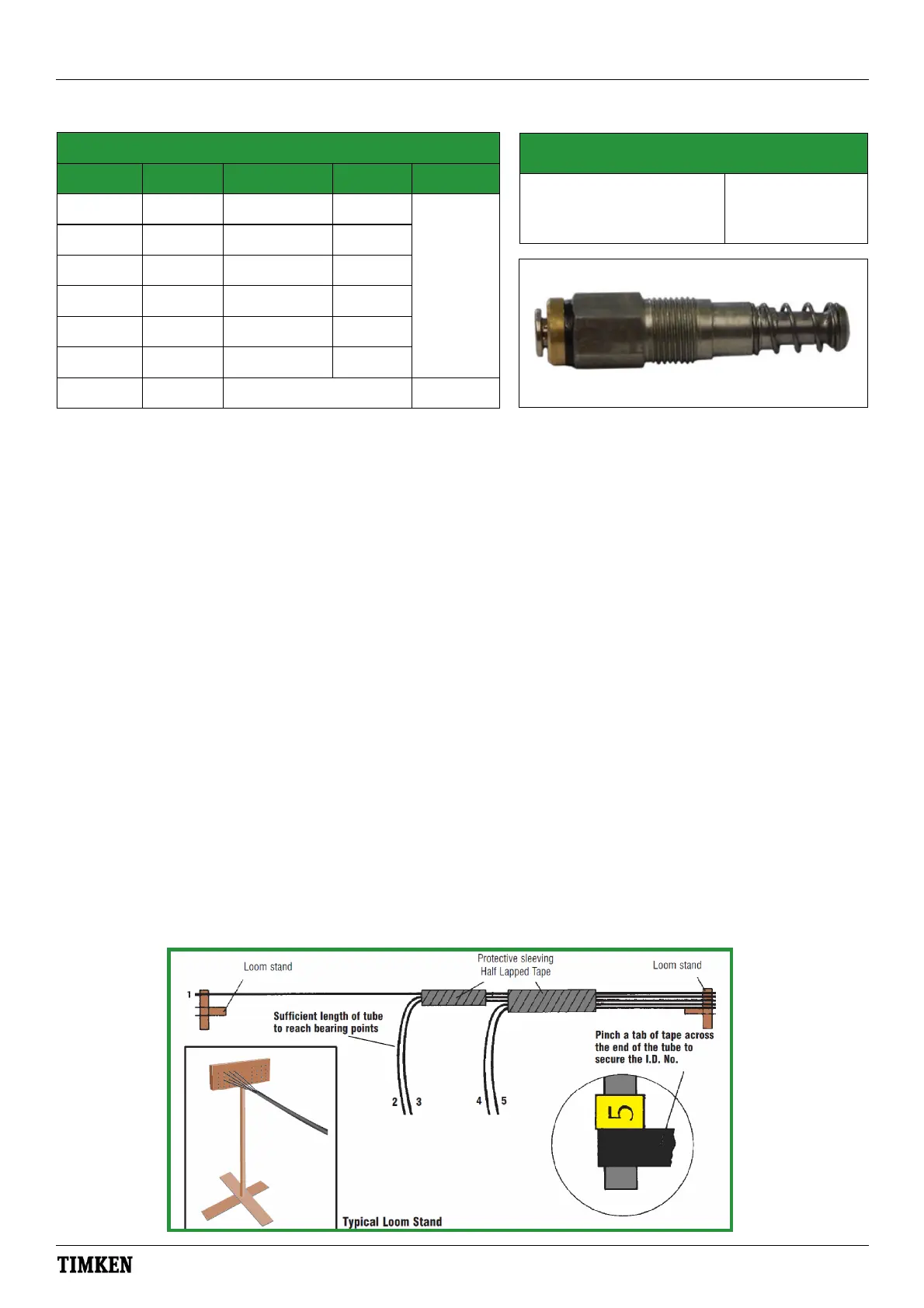

Standard Pumping Units for AC3 Pumps.

Part No. ‘F’ No. Output/stoke Color Outlet Size

78033‐PL F800091 0.010cc Red

Ø4mmOD

PushType

78034‐PL F800092 0.015cc Green

78035‐PL F800093 0.025cc Yellow

78036‐PL F800094 0.040cc Blue

78037‐PL F800095 0.060cc Grey

78038‐PL F800096 0.100cc Black

34237‐402 F800108

N/ABlankingPlug

MaximumOutputpressure

fromeachPumpingUnit

1740PSI/120Bar

Output pressure

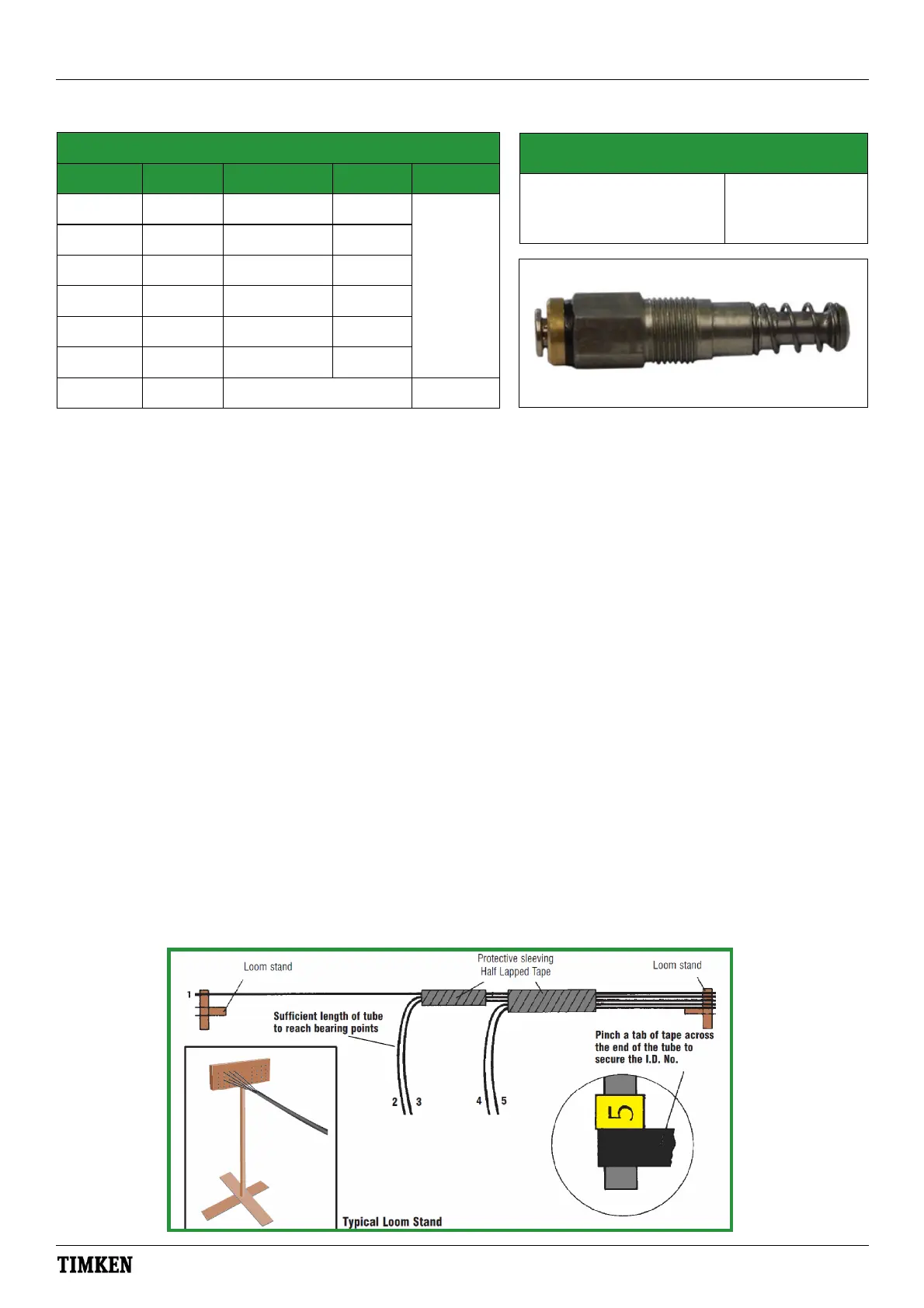

Making the Looms

ThislubricantdistribuonlinesshouldbemadeupofGroeneveldØ4mm,semi‐rigid,nylontubing.Itisrecommendedthatthe—

tubingispre‐filledwithgreasetosaveontherequirementtoprimethesystemonceinstalled.

Fromthepumpposionestablishthemostconvenientrouteforthelubricaonlines.Itmaybepreferredtogroupthelinesinto

loomsdependingonpumplocaonandquantyandposioningofthegreasepoints.Ifgroupingthelines,intolooms,allow‐

sufficientlengthforconnecontothebulkheadoutletconnectorsandthebearings,makinganallowanceformovementonthe

machinery.Inconjunconwiththe‘Installaon Record’sheet(seepage16),fitthenumberidenficaonsleevestothelinesatthe

pumpandbearingends.Theloomshouldbeprotectedalongitslengthwiththeconduit/spiralbinding/sleevingand/ortape(for

partnumberssee‘Accessories’ onpage13).

Installaon:

Workingfromthefurthestpointfromthepump,feedthelubricaonlinesthroughthemachinefollowingexisngmachineservices,

wherepossible.Ensurethatthelubricaonlinesareposionedtofitthebearingfings.Whereabearingisonamovingpart,‐

ensurethatthelineissufficienttoallowforfullmovement.Toavoidrubbingorfriconwithmovingparts,grommetsorprotecve

sleevingshouldbeused.Also,dependingontheseverityofmovement,compressionfingsmaybepreferredatthebearingpoints.

Connecng the lines:

Cuteachlubricaonlinetolengthensuringaclean,squarecutisachieved.Connecttothebearingusingpushfitorcompression

connectors.ENSURE TUBING IS PUSHED FIRMLY INTO CONNECTOR. TEST ASSEMBLY BY PULLING FIRMLY ON THE LINE AFTER

INSTALLATION.UsingtheSystemSpecificaonSheetconnecttheloomtocorrespondingnumberedpumpingunits.When‐

runningthetubingintothepumpingunits,togivetheloomstrengthandrigidity,thetubesshouldbeclippedtogethertoforman

arrangementwithanoffsetfromthepumpof50to60mm(2”‐2‐1/2”).Thestarngpointfortheloomcanbeasrequired.

Starngwiththeboomrowofoutletsandpumpingunit“1”,theloomshouldthenrunaroundthepump,thenontoconnect

withthenextrowofpumpingunitssothattheloomtakestheformofaspiral,andsoonunlallpumpingunitsareconnected.

Tubesshouldbekepttogetherwithe‐clipsatintervalsofevery6pumpingunits.Theloom,orlooms,canthenberoutedonto

thechassisasrequired.

Note:Alldamagedpipeworkshouldbereplacedusinggenuinespareparts,failuretodosocancausesystemmalfunconsand

safetyissues.

2

Loading...

Loading...