SAFETY WARNING

Electrical Work

All electrical work should be performed by a qualified electrician in

accordance with the latest edition of the National Electrical Code,

local codes and regulations.

Shock Hazard

A faulty motor or wiring can cause electrical shock that could be fatal,

whether touched directly or conducted through standing water. For this

reason, proper grounding of the pump to the power supply's grounding

terminal is required for safe installation and operation.

In all installations, the above-ground metal plumbing should be

connected to the power supply ground as described in Article 250-80

of the National Electrical Code.

Codes

Example

Pump version

A *Basic version pump

U *NEMA version pump

B Oversize motor,

one flange size bigger

F CR pump for high

temperatures (Cool-Top™)

H Horizontal version

HS High pressure pump with over-

synchronous speed and

reversed direction of rotation

I Different pressure rating

K Low NPSH

M Magnetic drive

P Undersize motor

R Horizontal version with

bearing bracket

SF High pressure pump with

reversed chamber stack and

direction of rotation

T Oversize motor,

two flange sizes bigger

X **Special version

Pipe connection

A Oval flange

B NPT thread

C Clamp coupling

CA FlexiClamp

CX TriClamp

F

DIN flange

G ANSI flange

J JIS flange

N Changed diameter of ports

O Externally threaded, union

P PJE coupling

X Special version

Materials

A Basic version

D Carbon-graphite filled PTFE

(bearings)

G Stainless steel parts of 316 SS

GI Base plate and flanges of

316 SS

I Stainless steel parts of 304 SS

II Base plate and flange of 304 SS

K Bronze (bearings)

S SiC bearing ring + PTFE neck

ring (only CR, CRN 32 to 90)

T Titanium

X Special version

Code for rubber parts

E EPDM

F FXM (Flouraz®)

K FFKM (Kalrez®)

V FKM (Viton®)

Shaft seal

A O-ring seal with fixed driver

B Rubber bellows seal

D O-ring seal, balanced

E Cartridge seal with O-ring

H Balanced cartridge seal with O-ring

K Cartridge shaft seal with

metal bellows

O Double seal, back to back

P Double seal, tandem

R O-ring seal with reduced face

X Special version

B Carbon, synthetic

resin-impregnated

H Cemented tungsten carbide,

embedded hybrid

Q Silicon carbide

U Cemented tungsten carbide

E EPDM

F FXM (Flouraz®)

K FFKM (Kalrez®)

V FKM (Viton®)

* In August 2003 the NEMA pump code was discontinued for all material

numbers created by GRUNDFOS manufacturing companies in North America.

The NEMA version pump code will still remain in effect for existing material

numbers. NEMA version pumps built in North America after this change will

have either an A or U as the pump version code depending on the date the

material number was created.

** If a pump incorporates more than two pump versions, the code for the pump

version is X. X also indicates special pump versions not listed above.

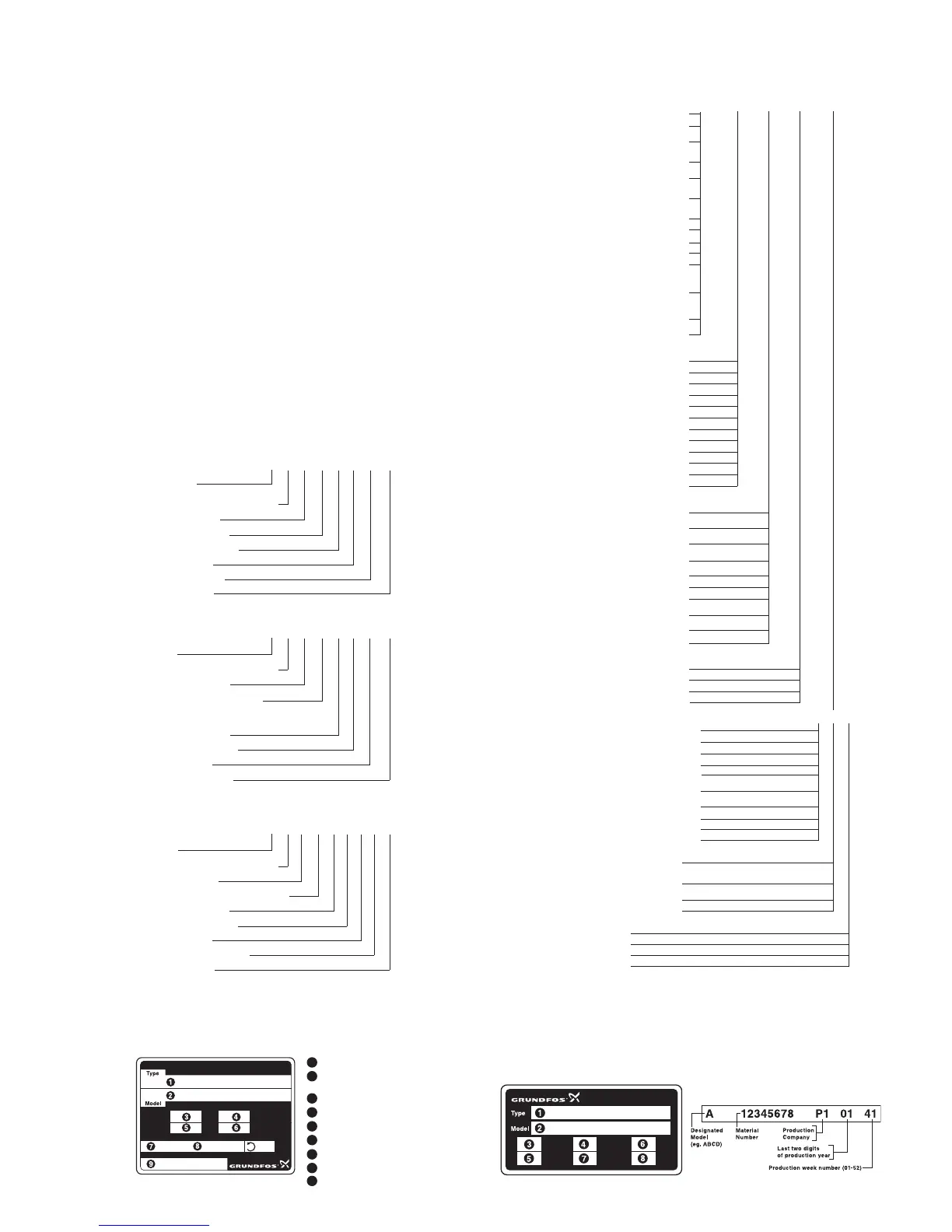

CR, CRX, CRN 8 and 16

Example

Type range:

CR, CRN

Rated flow rate in [m³/h] (x 5=GPM)

Number of stages x 10

Number of impellers (used only

if the pump has fewer impellers

than stages)

Code for pump version

Code for pipe connection

Code for materials

Code for shaft seal and

rubber parts

Type key

CR, CRI, CRN 1s, 1, 3, 5, 10, 15, and 20

Example

Type range:

CR, CRI, CRN

Rated flow rate in [m³/h] (x 5=GPM)

Number of impellers

Code for pump version

Code for pipe connection

Code for materials

Code for rubber parts

Code for shaft seal

HQQE

2

Model Key

QH

P

PSI max ˚F max

N

GPM FEET

HP RPM

QH

P

N

GPM FEET

HP

PSI ˚F max

RPM

CR 3 -10 A FGJ A HQQE

UFGJ HQQEAE

E

CR 16 /2 U G AUUEA

CR, CRN 32, 45, 64, AND 90

Example

Type range:

CR, CRN

Rated flow rate in [m³/h] (x 5=GPM)

Number of impellers

Number of reduced diameter impellers

Code for pump version

Code for pipe connection

Code for materials

Code for rubber pump parts

Code for shaft seal

CR 32 -2 -1 U G KUHEAE

- 30

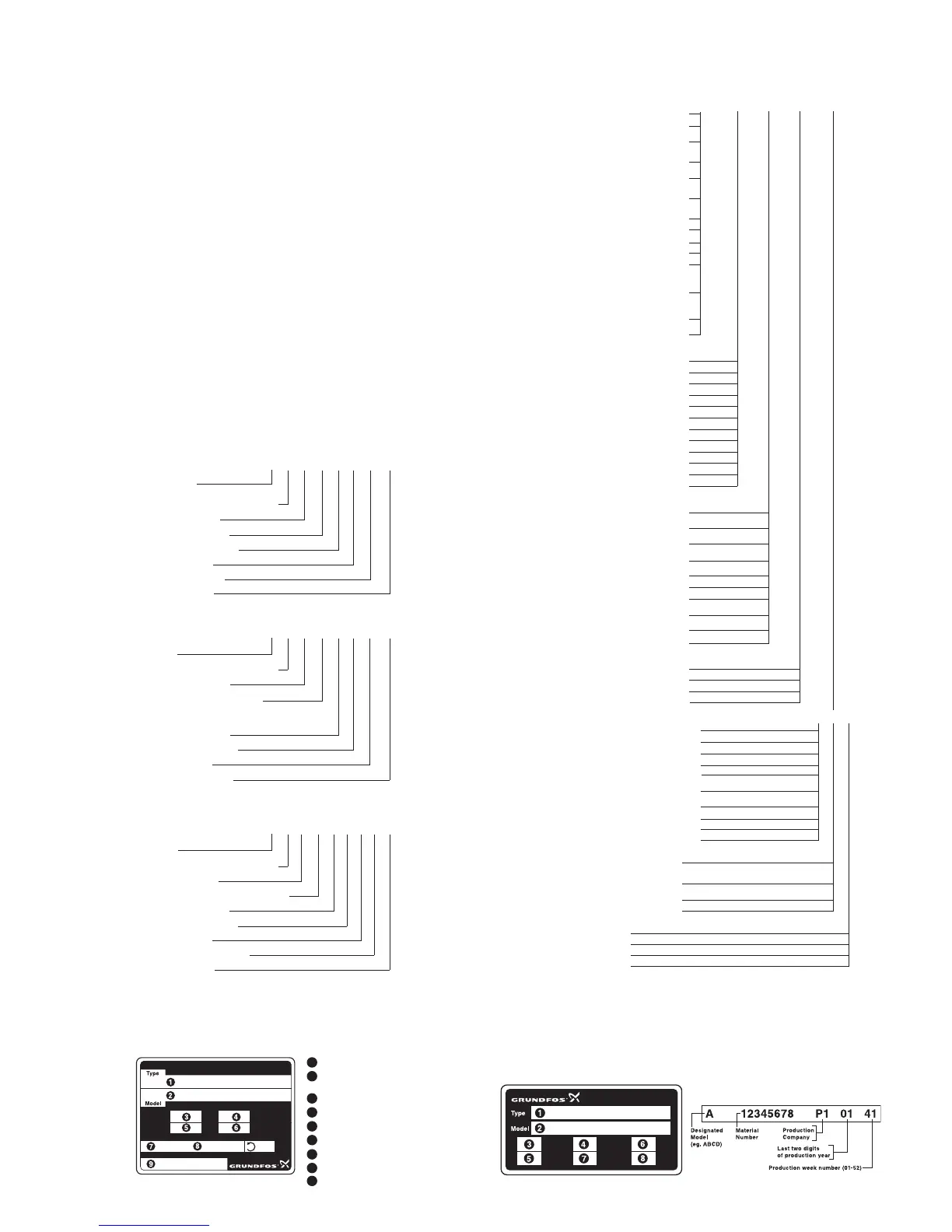

Nameplate Data

1 Type designation

2 Model, material number,

production code

3

Gallons per minute at rated RPM

4 Head in feet at nameplate flow

5 Pump horsepower

6 Rated RPM

7

Maximum PSI

8 Maximum fluid temperature

9 Production country

LCPTL003_CR I&O_Rev0104.qxd 1/26/2004 11:58 AM Page 2

Loading...

Loading...