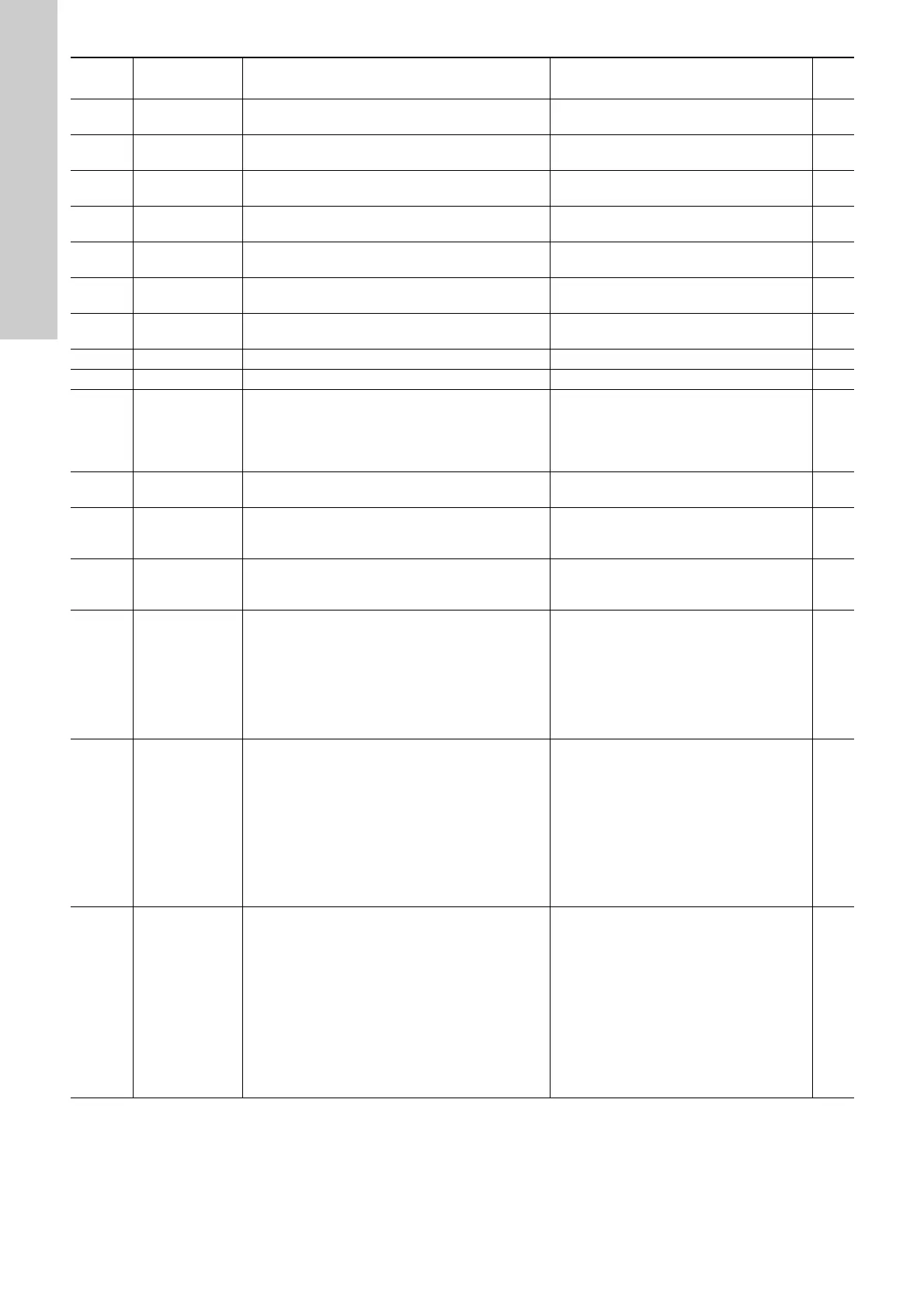

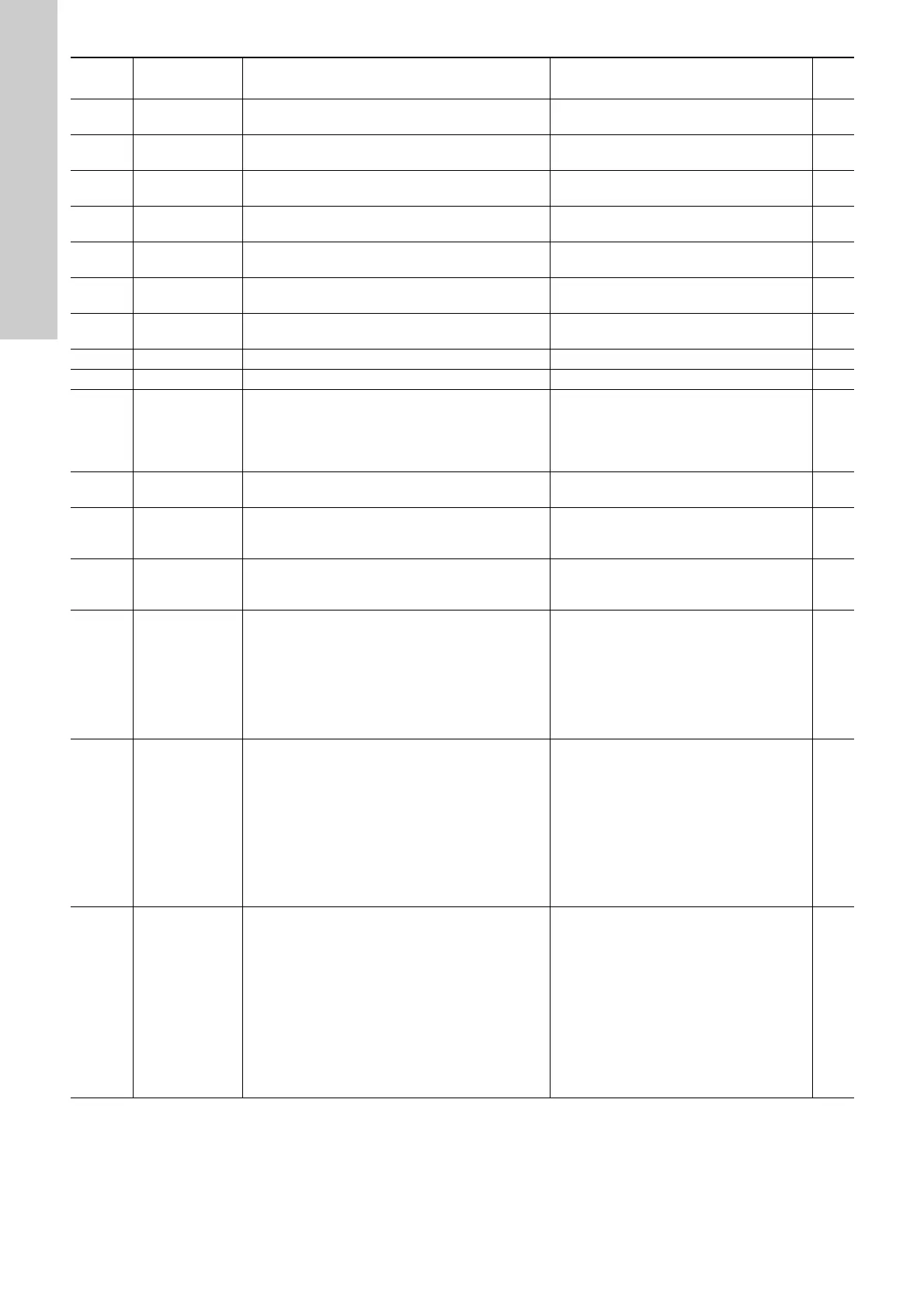

English (GB)

14

92 No-flow

A no-load situation has been detected in the

system.

See parameter group 22-2. A

93 Dry pump

A no-flow situation and high speed indicates that the

pump has run dry.

See parameter group 22-2. A

94 End of curve

Feedback stays lower than the setpoint, which may

indicate leakage in the pipe system.

See parameter group 22-5. A

95 Broken belt

Torque is below the torque level set for no-load,

indicating a broken belt.

See parameter group 22-6. A

96 Start delayed

Motor start is delayed due to active short-cycle

protection.

See parameter group 22-7. A

97 Stop delayed

Stopping the motor is delayed due to active short-

cycle protection.

See parameter group 22-7. W

98 Clock fault

The time is not set or RTC clock (if mounted) has

failed.

See parameter group 0-7. W

99 Locked rotor The rotor is blocked. Contact Grundfos Service. A

100 Derag limit fault The deragging feature failed during execution. Check the pump impeller for blockage. A

104 Mixing fan fault

The fan is not operating. The fan monitor checks

that the fan is spinning at power-up or whenever the

mixing fan is turned on. The mixing-fan fault can be

configured as a warning or an alarm trip in

parameter "14-53 Fan Monitor".

Cycle power to the drive to determine if the

warning or alarm returns.

W/A

148

System

temperature

One or more of the system temperature

measurements is too high.

Contact Grundfos Service. W/A

200 Fire mode

The drive is operating in fire mode. The warning

clears when fire mode is removed. Refer to the fire

mode data in the alarm log.

Contact Grundfos Service. W

201

Fire mode was

active

The drive has entered fire mode. Cycle power to the

unit to remove the warning. Refer to the fire mode

data in the alarm log.

Contact Grundfos Service. W

243 Brake IGBT

This alarm is only for multi-drive systems. It is

equivalent to alarm 27, Brake chopper fault.

• The DC fuse is blown.

• The brake jumper is not in position.

• The Klixon switch opened due to an

overtemperature condition in the brake resistor.

The report value in the alarm log indicates

which drive module generated the alarm:

1: Left drive module.

2: Second drive module from left.

3: Third drive module from left (in 4-module

systems).

4: Fourth drive module from left (in 4-module

systems).

A

244

Heat sink

temperature

The maximum temperature of the heat sink has

been exceeded. The temperature fault cannot reset

until the temperature drops below a defined heat

sink temperature.

The trip and reset points are different based on the

power size. This alarm is equivalent to alarm 29,

"Heat Sink Temp".

• Check the ambient temperature, it may be

too high.

• Check the length of the motor cables.

They may be too long.

• Incorrect airflow clearance above or

below the AC drive.

• Check for blocked airflow around the unit.

• Check to see if the heat sink fan is

damaged.

• Check if the heat sink is dirty.

A

245 Heat sink sensor

No feedback from the heat sink temperature sensor.

The signal from the IGBT thermal sensor is not

available on the power card. This alarm is

equivalent to alarm 39, Heat sink sensor.

The report value in the alarm log indicates which

drive module generated the alarm:

1: Left drive module.

2: Second drive module from left.

3: Third drive module from left (in 4-module

systems).

4: Fourth drive module from left (in 4-module

systems).

Check the following:

• Power card.

• Gate drive card.

• Ribbon cable between the power card and

the gate drive card.

A

Alarm

code

Description Cause Remedy Type

Loading...

Loading...