English (GB)

5

3.2.3 Vibration dampers

Vibration dampers may be required to prevent pump

vibrations from being transmitted to the building or

the pipes. In order to select the right type of vibration

damper, you need this information:

• Forces transmitted through the damper.

• Motor speed. Take the motor speed into account

in the case of speed control.

• Desired dampening in %. The recommended

value is 70 %.

The choice of vibration dampers differs from

installation to installation. In certain cases a wrong

damper may increase the vibration level. Vibration

dampers must therefore be sized by the supplier of

the vibration dampers.

3.2.4 Expansion joints

Expansion joints provide these advantages:

• absorption of thermal expansion and contraction

of pipes caused by variations in liquid

temperature

• reduction of mechanical influences in connection

with pressure surges in the pipes

• isolation of structure-borne noise in the pipes

(only rubber bellows expansion joints).

Fit the expansion joints at a minimum distance of 2

pipe diameters (DN) away from the pump flange on

the inlet side. This prevents turbulence in the joints,

thus ensuring optimum inlet conditions and minimum

pressure drop on the outlet side.

At flow velocities greater than 2.4 m/s, we

recommend that you fit larger expansion joints

matching the pipes.

3.2.5 Foundation and preliminary alignment

procedure

The foundation and preliminary alignment procedure

has four steps:

1. pouring of foundation

2. shimming of base frame

3. preliminary alignment

4. grouting.

Pouring of foundation

We recommend the following procedure to ensure a

good foundation:

1. Pour the foundation without interruptions to

within 19-32 mm of the final level. Use vibrators

to ensure that the concrete is evenly distributed.

The top surface must be well scored and grooved

before the concrete sets. This provides a bonding

surface for the grout.

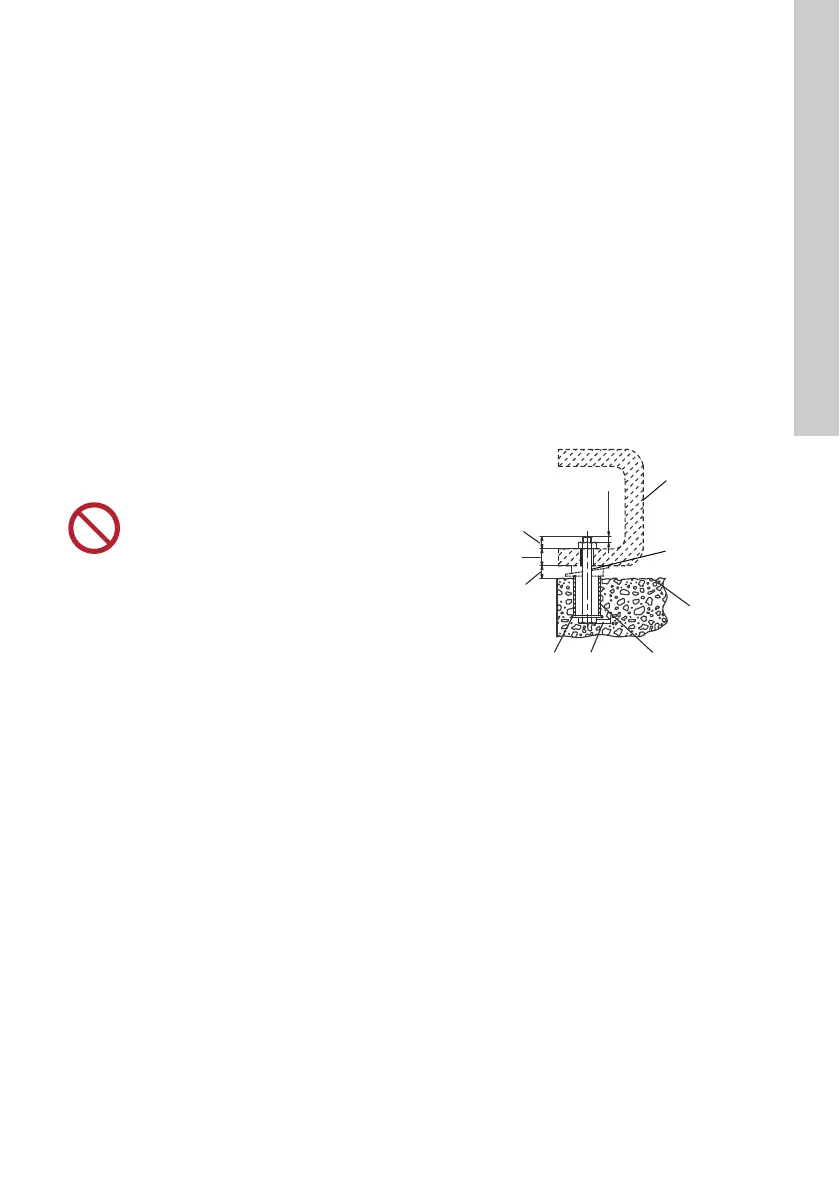

2. Embed anchor bolts in the concrete as shown in

fig. 4. Allow enough bolt length to reach through

grout, shims, lower base frame, nuts and

washers.

Fig. 4 Typical anchor bolt design

Let the foundation cure for several days before the

base frame is shimmed and grouted.

Do not fit expansion joints to make up for

inaccuracies in the pipes, such as centre

displacement or misalignment of flanges.

TM04 0383 0608

Bolt length

above base

frame

Thickness of

base frame

19 to 32 mm

allowance for

grout

Base frame

Top of

foundation left

rough

Pipe sleeveLugWasher

Wedges and

shims left in

place

Loading...

Loading...