English (GB)

8

5. Electrical connection

5.1 General

The electrical connection must be carried out by an

authorised electrician in accordance with local

regulations.

The supply voltage, rated maximum current and

cos φ are displayed on the separate nameplate that

must be fitted close to the installation site.

The required voltage quality for Grundfos MS and

MMS asynchronous submersible motors, measured

at the motor terminals, is - 10 % / + 6 % of the

nominal voltage during continuous operation

(including variation in the mains voltage and losses

in cables).

Furthermore, make sure there is voltage symmetry in

the power supply lines, that is, the difference of

voltage between the individual phases is the same.

See also section 11. Checking the motor and cable,

item 2.

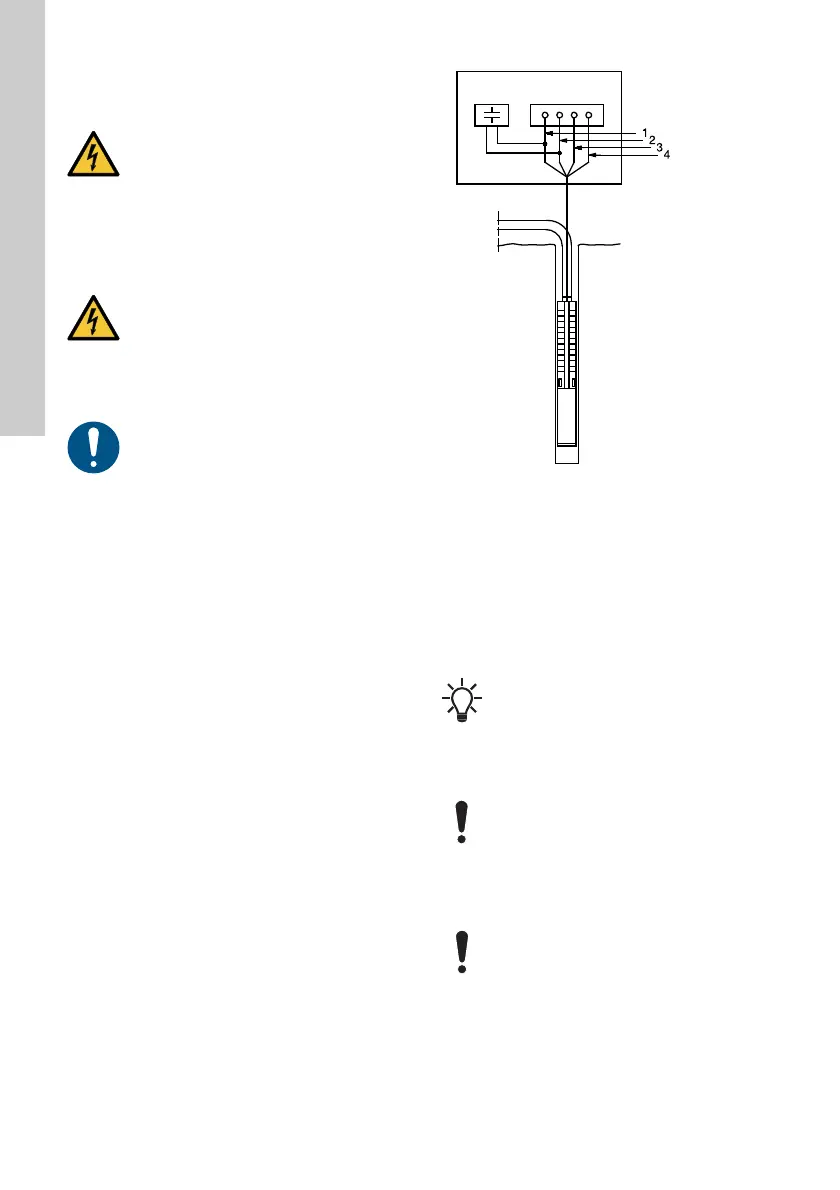

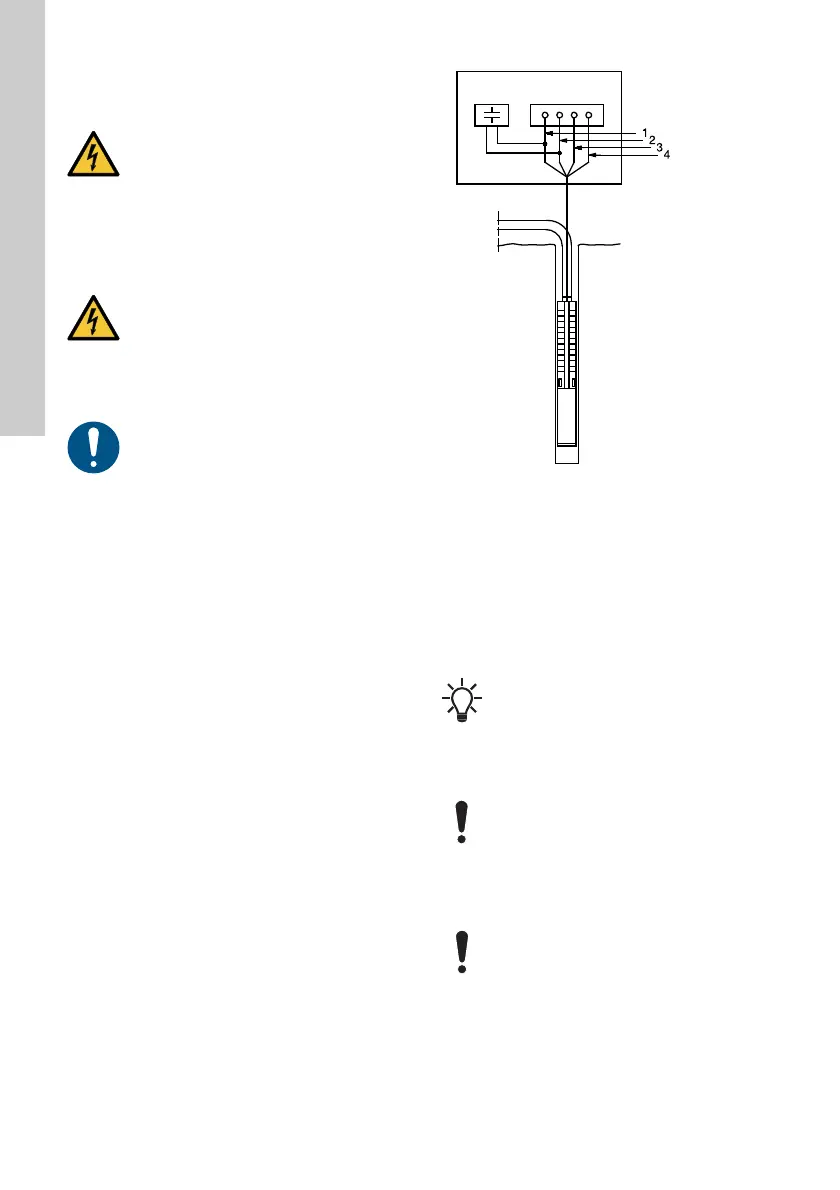

If MS motors with a built-in temperature transmitter

(Tempcon) are not installed together with an MP 204

motor protection unit, they must be connected to a

0.47 μF X2 capacitor (IEC 384-14) approved for the

actual voltage. The capacitor must be connected to

the two phases to which the temperature transmitter

is connected. See fig. 6.

Fig. 6 Connection of capacitor

The motors are wound for direct-on-line (DOL) or

star-delta starting, and the starting current is

between four and six times the rated current of the

motor.

The run-up time of the motor is only about 0.1

second. Direct-on-line starting is therefore normally

approved by the power supply company.

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply before

starting any work on the product.

- Make sure that the power supply cannot

be accidentally switched on.

DANGER

Electric shock

Death or serious personal injury

- The pump must be earthed.

- The pump must be connected to an

external main switch and must be

provided with means to locking it in the

OFF (isolated) position. Type and

requirements are specified in

EN 60204-1, 5.3.2

The electrical connection must be carried

out by an authorised person in accordance

with local regulations.

TM00 7100 0696

If an MS motor with temperature

transmitter is connected to a frequency

converter, he fuse melts and the

transmitter becomes inactive. The

transmitter can no longer be reactivated,

consequently, the motor thereafter

operates like one without a temperature

transmitter.

To enable monitoring of the motor

temperature when running at frequency

converter operation, Grundfos

recommends that a Pt100 or a Pt1000

sensor be installed.

During frequency converter operation, it is

not advisable to run the motor at a

frequency higher than the rated frequency

(50 or 60 Hz). In connection with pump

operation, it is important never to reduce

the frequency (and consequently the

speed) to such a level that the necessary

flow of cooling liquid past the motor is no

longer ensured.

0.47 μF

1 = L1: Brown

2 = L2: Black

3 = L3: Grey

4 = PE: Yellow and green

Loading...

Loading...