16

5.52.420.00.01.07

9.5 Adjustment - limit switch for lifting

If desired the chain hoist can be fitted with a limit

switch for lifting GTES 51-67 or GTES 51-180.

It allows to adjust any switching point desired, for

example the limit positions of upper and lower

hook position. The slipping clutch incorporated in

the hoist serves as emergency stop.

If the chain hoist is supplied with switch included,

a switching point for upper and lower hook

position is preset.

The setting can be adjusted at the set screws 1

and 2 with a screw driver ø 4mm or 4mm

hexagon socket screw key. The table shows the

hook path for one turn of the set screw.

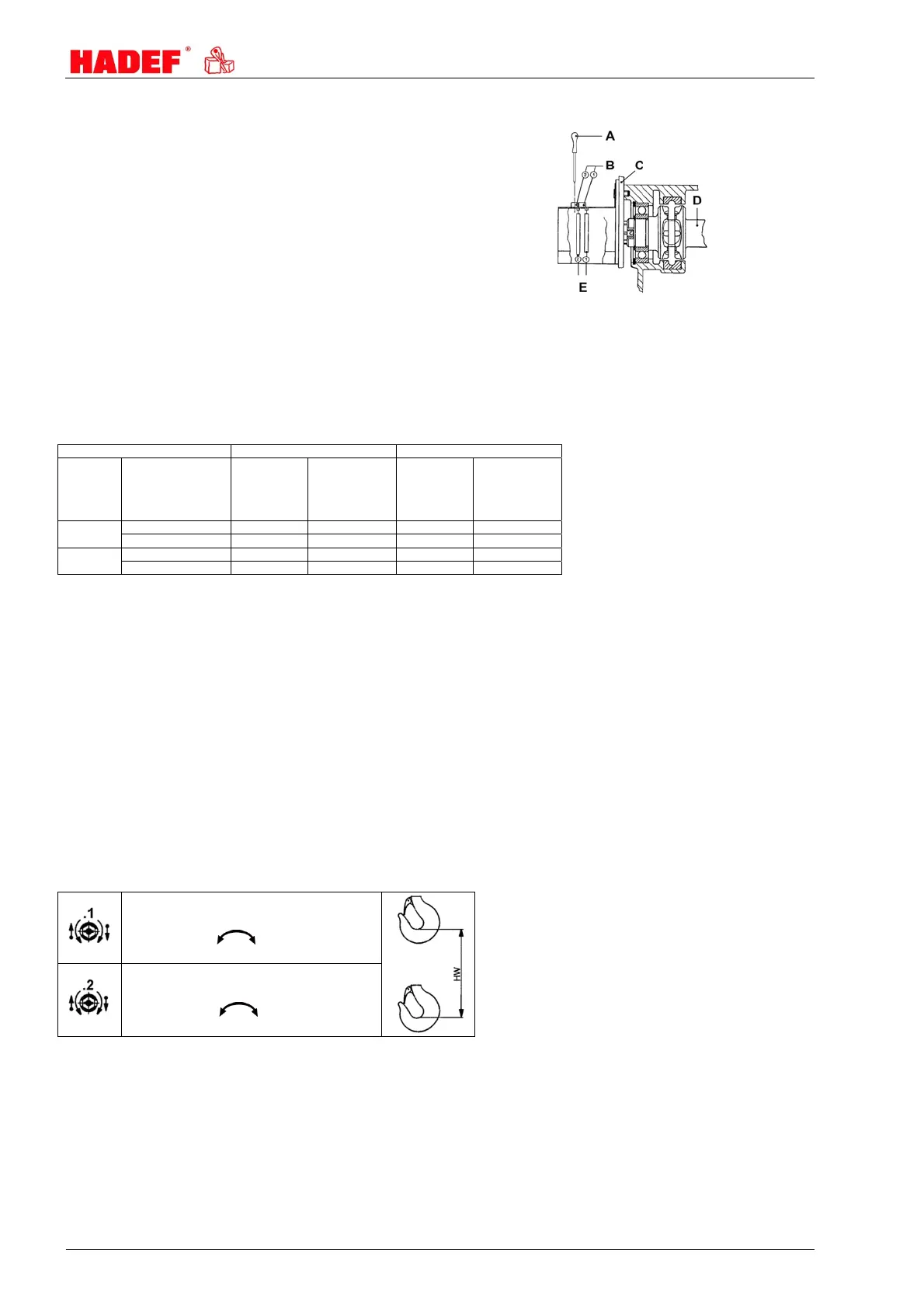

A Adjustment with screw driver ø 4mm

B set screw

C Adapter

D Chain sprocket shaft

E Control cams

125 kg/1 up to 1000 kg/2 1000 kg/1 and 2000 kg/2

chain falls type of limit switch for

lifting

hook path hook path per

turn of set screw

1 and 2

mm

hook path

hook path per

turn of set screw

1 and 2

mm

1 GTES 51 - 67 <=9m 92 <=12m 130

GTES 51 - 180 >=9m 250 >=12m 350

2 GTES 51 - 67 <=4m 46 <=6m 65

GTES 51 - 180 >=4m 125 >=6m 175

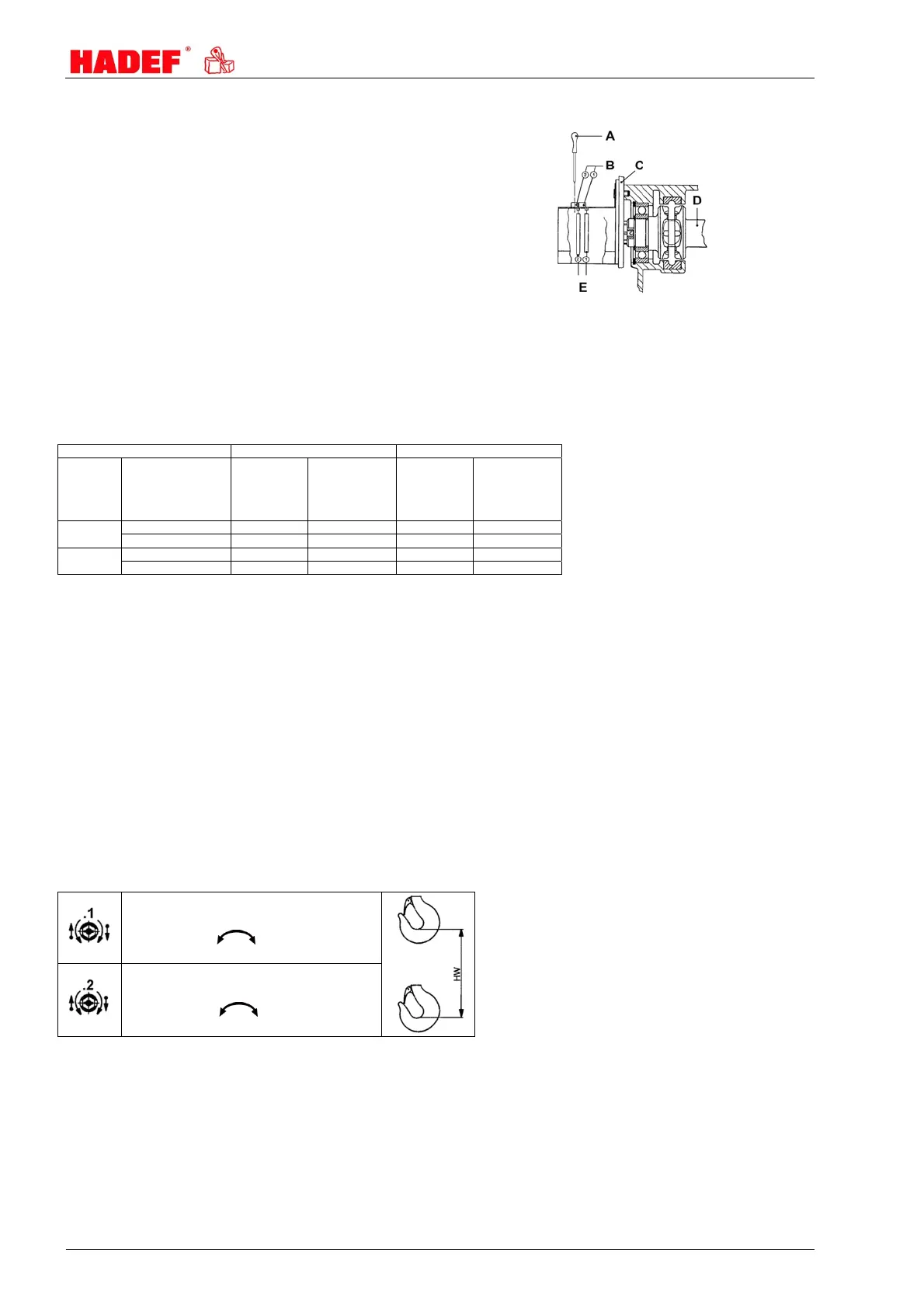

9.6 Setting of the switching points

set screw 1 "switching point 1 (lifting)"

The switching point can be set at any desired point

between upper and lower hook path limit. In order

to adjust move the load hook to the desired

position, which is possible by turning the set screw

1 to the left side. Afterwards turn the set screw 1 as

far to the right side until the switching contact

switches audible. 114 turns of the set screw mean

360° at the cam.

Drive two times into the desired hook position (1

creep speed, 2 main speed) and check the

switching point, adjust if necessary. The load

attaching device may not touch the housing and

thereby activate the slipping clutch.

set screw 2 "switching point 2 (lowering)"

The switching point can be set at any desired

point between upper and lower hook path limit. In

order to adjust move the load hook to the desired

position, which is possible by turning the set

screw 2 to the right side. Afterwards turn the set

screw 2 as far to the left side until the switching

contact switches audible. 114 turns of the set

screw mean 360° at the cam.

Drive two times into the desired hook position (1

creep speed, 2 main speed) and check the

switching point, adjust if necessary. The chain

attaching part may not touch the housing and

thereby activate the slipping clutch.

switching point 1 (lifting)

114 = 360°

switching point 2 (lowering)

114 = 360°

10 Safety check

Before putting into service initially or when putting back into service, it must be checked whether:

All fastening screws (if existent), socket pins, flap socket and safety devices are tightened and secured.

The oil levels in the gear boxes are sufficient.

All movements of the load comply with the symbols on the control switch.

The chains are correctly placed, oiled and in good condition.

11 Functional test

Loading...

Loading...