5.52.420.00.01.07

21

These conditions have to be written down in the test book.

The owner/user is responsible to make sure that these conditions are observed.

13.2 Periodic checks

Independently from the regulations of the individual countries, lifting devices must be checked at least yearly

by a qualified person or licensed qualified person regarding its functional safety.

13.2.1 Components to be checked

The following must be checked:

Dimensions of load chain, load hooks, pawls, bolts, ratchet wheels, brake linings.

The dimensions must be compared to the dimensions in the tables.

A visual inspection for deformations, cracks and corrosion must be carried out.

13.2.2 Inspection intervals

at

commissioning

daily

checks

1st maintenance

after

3 months

Inspection

and

maintenance

every

3 months

Inspection

and

maintenance

every

12 months

Inspection

and

maintenance

every

36/60 months

Inspection of the equipment by

a qualified person

(periodic inspection)

X

screw connections X X

brake function - brake discs X X

overload protection as slipping clutch

(if relevant)

X X

overload protection by current cut-off (electric hoist) (if relevant) X X

overload protection by air relieve valve

(pneumatic hoist) (if relevant)

X X

load chain, clean and oil X X*) X X

load chain, elongation and wear X

load hook, cracks and deformation X

Bearings of chain pulleys,

check and lubricate

X

Hoist gear, oil change X*)

Trolley wheels, wear X

Trolley wheels, lubricate toothed wheels X*) X*) X*)

*) see chapter "maintenance"

13.3 Checking the load chain

CAUTION!

The load chain must be tested over its entire length!

The measure of the load chain must be carried out especially in the areas which are subject to the highest

wear. Through the lifting movement, these are the contact points of the chain with sprocket wheel and

deflection pulleys.

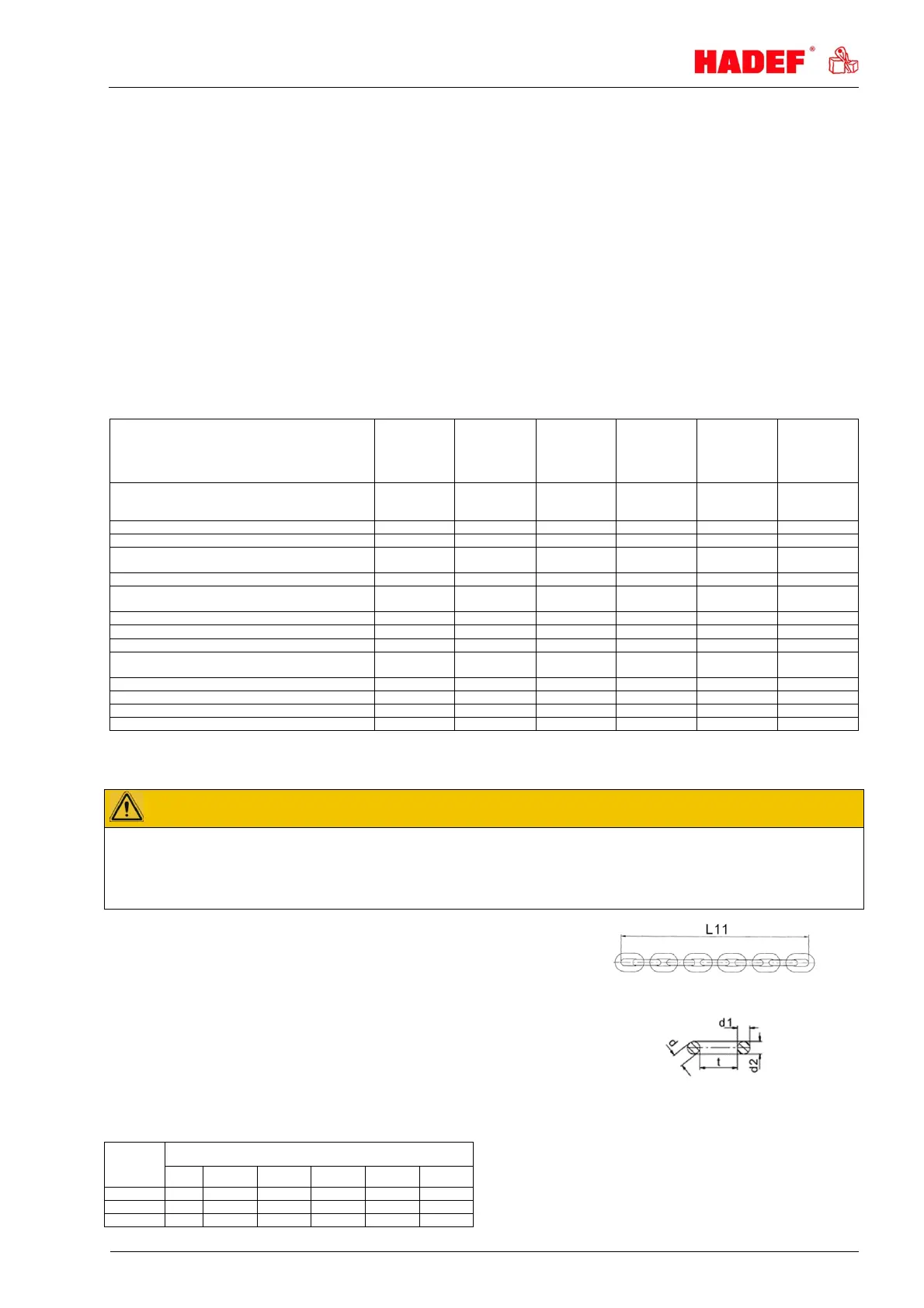

acc. DIN 685-part 5

L11 = pitch increase over 11 chain links

L1 = pitch increase over 1 chain link

Illustration 18

dm= detected link diameter (d1+d2)/2

Illustration 19

Chain dimensions

Dimension

mm

Chain dimension

5x15 7x21 9x27 11,3x31 16x45 23,5x66

L11 171,4 238,8 300,8 348,1 505,6 743,0

L1 16,0 22,4 28,1 32,7 47,4 69,5

dm 4,6 6,5 8,2 10,2 14,4 21,2

Loading...

Loading...