20

0

50

100

150

200

250

300

350

400

450

-300 -250 -200 -150 -100 -50 0 50 100 150 200

a (mm)

Fr (kN)

0

5000

10000

15000

20000

25000

30000

35000

40000

45000

50000

55000

60000

65000

70000

75000

80000

85000

90000

95000

100000

Fr (lbf)

10 rpm

40 rpm

0

50

100

150

200

250

-300 -250 -200 -150 -100 -50 0 50 100 150 200

a (mm)

Fr (kN)

0

5000

10000

15000

20000

25000

30000

35000

40000

45000

50000

55000

Fr (lbf)

20 rpm

90 rpm

0

50

100

150

200

250

-100 -50 0 50 100 150 200

a (mm)

Fr (kN)

0

5000

10000

15000

20000

25000

30000

35000

40000

45000

50000

55000

Fr (lbf)

20 rpm

90 rpm

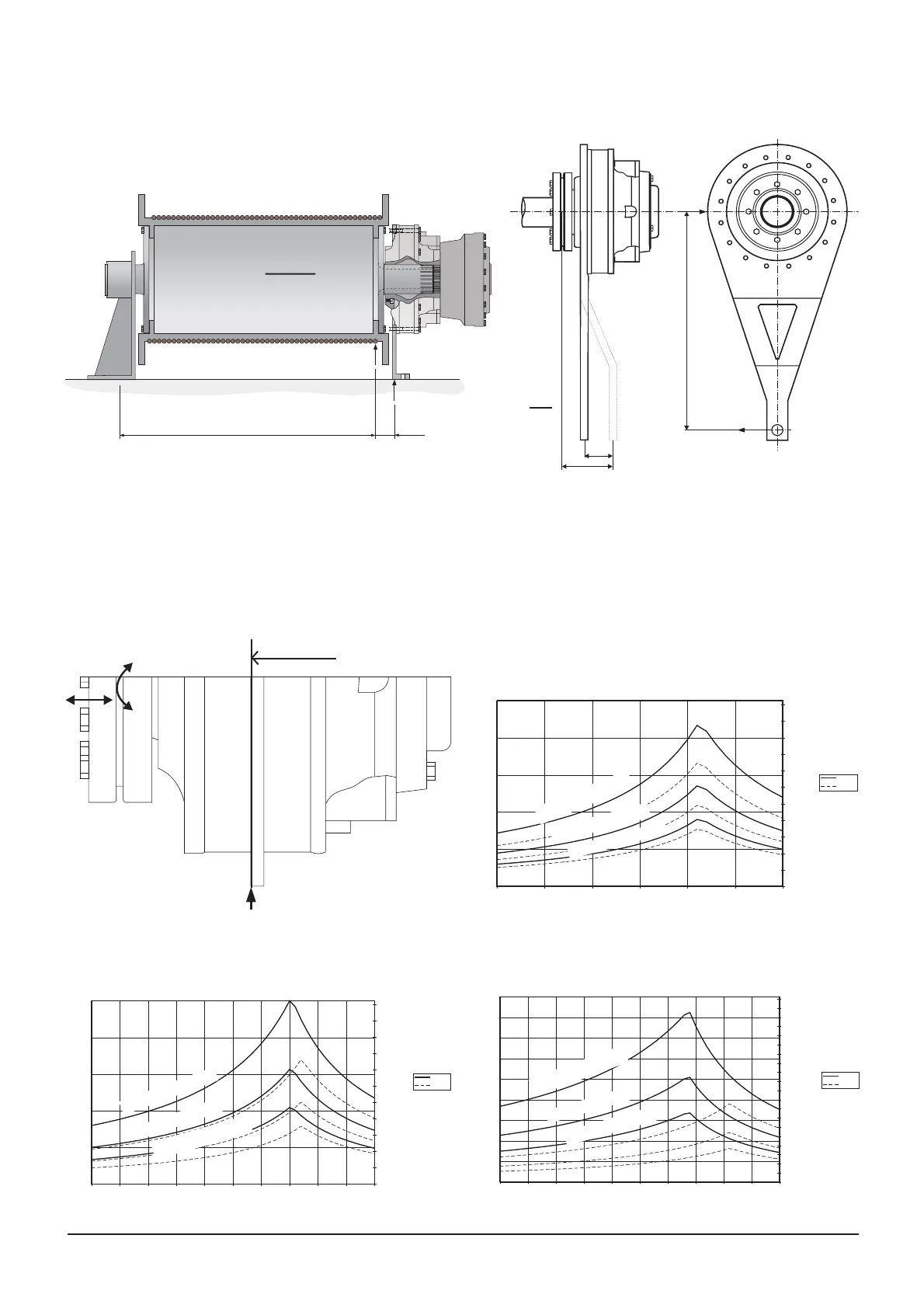

Recommended external loads for Compact

If not standard torque arms TCA are used, forces

must be checked for main bearings and coupling.

a = 0 mm

F

r

(kN)

F

r

(lbf)

Diagram 33 Motor type CA 100 and CA 140

F

r

(kN)

F

r

(lbf)

Diagram 34 Motor type CA 210

L

10h

= 1000 hrs.

L

10h

= 5000 hrs.

L

10h

= 20000 hrs.

L

1

0h

= 1000 hrs.

F

r

(kN)

F

r

(lbf)

Diagram 32 Motor type CA 50 and CA 70

Fixed shaft - torque arm mounted motor, viscosity 40/250 cSt, speed 100 rpm.

Torque arm is mounted at a = 0 mm on the motor.

Note: When Bracket mounted motor or higher external load, please contact Hägg lunds representative.

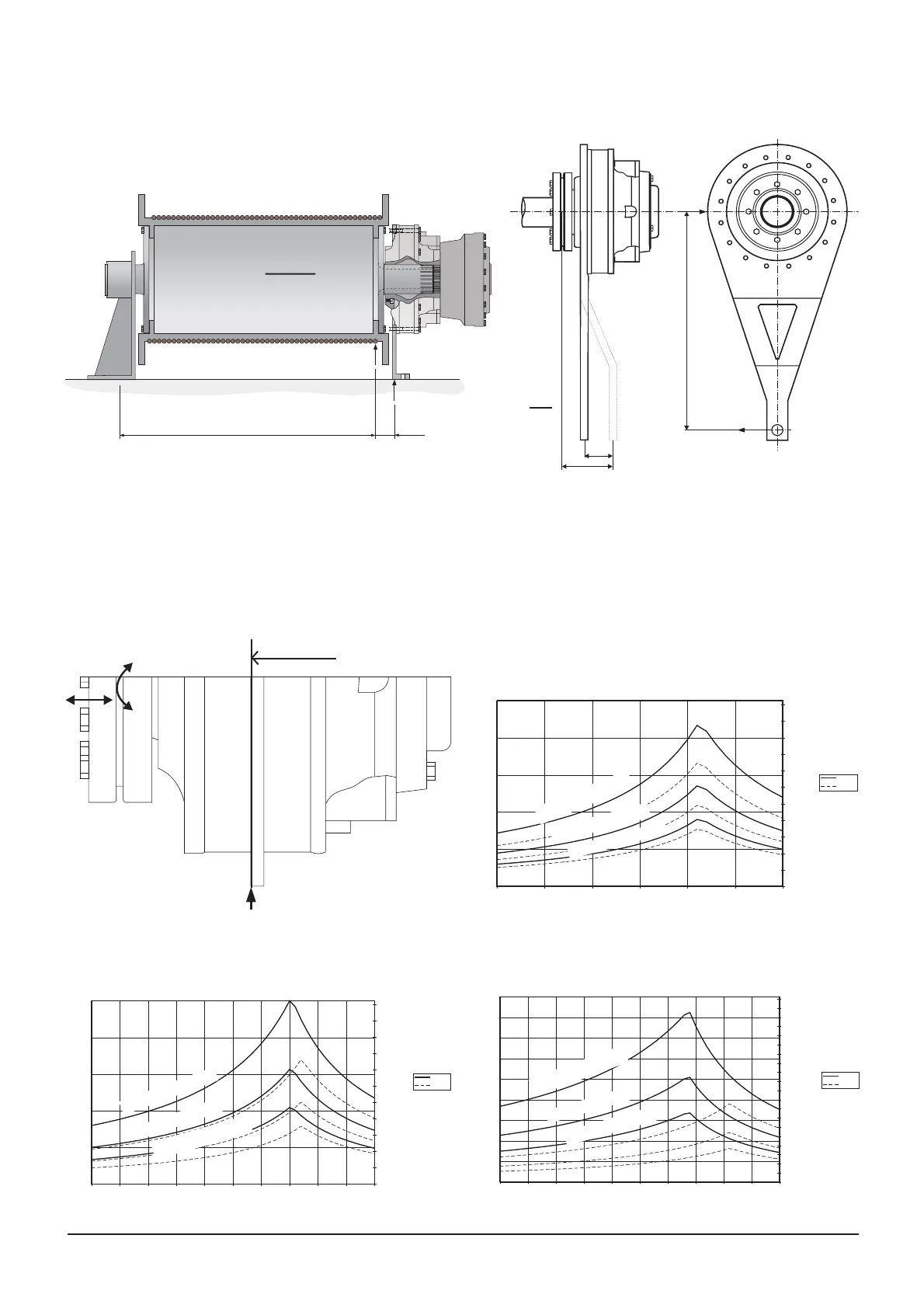

Permissible external loads

- The bracket must be designed so it does not give

extra external forces to the motor.

Motor mounted in winch - reaction forces.

F

r

= Total radial force on fi xed motor mounting

F

a

= Axial force acting on motor centerline

T = Output torque for motor

M

b

= Bending mo ment acting on hollow shaft

F

r

=

T

l

M

b

= F

r

· a

L

2

L

1

F

r

F

F

r

= F ·

L

1

+ L

2

L

2

F

r

F

r

a

l

F

a

M

b

F

r

L

1

0h

= 5000 hrs.

L

10h

= 20000 hrs.

L

1

0h

= 1000 hrs.

L

10h

= 5000 hrs.

L

10h

= 20000 hrs.

Loading...

Loading...