INSTALLATION

PAGE

ENGLISH

Step 4.2Step 4.1

Step 4.3

Table 1

Step 3.3

Step 3.4

Half union

Flare nut

Torque wrench

Spanner

Forced fastening without careful centering may

damage the threads and cause a leakage of gas.

Liquid side6.35mm(1/4") 18N.m/13.3Ft.lbs

Liquid/Gas side9.52mm(3/8") 42 N.m/30.1Ft.lbs

Gas side 12.7mm(1/2") 55N.m/40.6Ft.lbs

Gas side 15.88mm(5/8") 60 N.m/44.3Ft.lbs

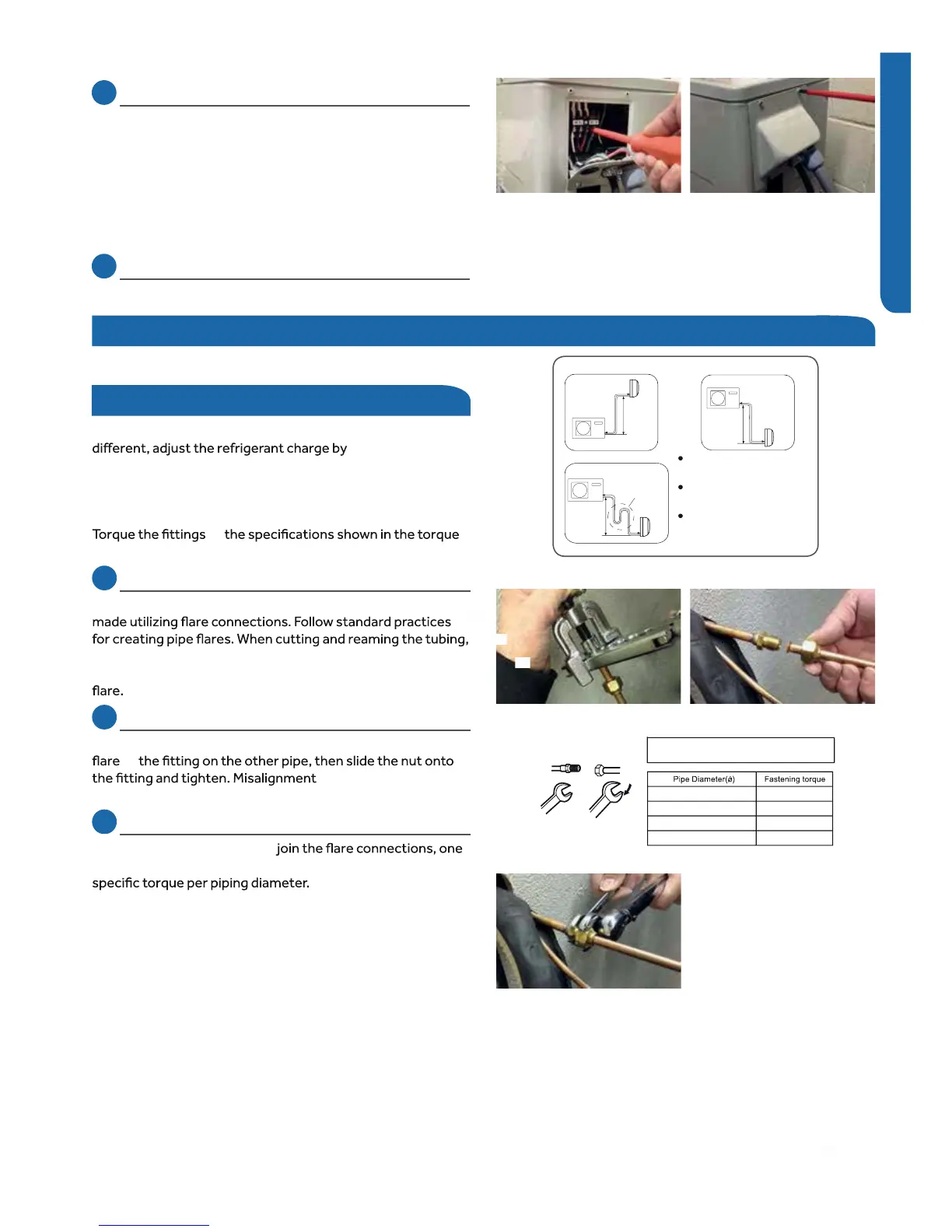

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

B

Outdoor unit

Indoor unit

Oil trap

CAUTION

Max. Elevation: A Max

= 33ft / 10m (09k / 12k)

= 50ft / 15m (18k / 24k)

In case the height of A is more than

15ft / 5m, an oil trap should be

installed every 16-23ft /5-7m

Max. Length: B Max

=50ft/15m(Advanced 9k/12k)

=66ft/20m(Tempo 9k/12k)

=83ft/25m(18k/24k)

Illustration 4

Step 4 - Interconnecting the Indoor and Outdoor Units

Piping

The standard lineset length is 25ft. If the installation length is

oz /ft. for the 9K,

12K, 18K, and 24K model. (Illustr ation 4)

to

chart.

4.1

Step - 4.1

Refrigerant piping connections for the mini-split system are

use caution to prevent dirt or debris from entering the tubing.

Remember to place the nut on the pipe before creating the

4.2

Step - 4.2

To join the line set to the service valve, directly align the piping

to

may result in a leaking

connection.

2.17

Step - 4.3

Two wrenches are required to

standard wrench, and one torque wrench. See Table 1 for the

*See Steps 2.11 - 2.13 & 3.2 - 3.4 for connecting the

electrical.

3.3

Step - 3.3

Connect the wiring for both the power source and indoor

wiring.

Wire the system according to applicable national / local

codes.

Verify that the wiring connections for the indoor unit match

wire for wire.

(1-1, 2-2, 3-3, Gnd-Gnd). Failure to wire the system correctly

may lead to improper operation or component damage.

3.4

Step - 3.4

Replace the cover plate.

37

0.2

service valves.

Loading...

Loading...