6

●

Control card and

changing the tempera

-

ture setting

Please refer to the FM-202 Instruction

manual.

●

Replacing the tip

Removing and inserting the tip:

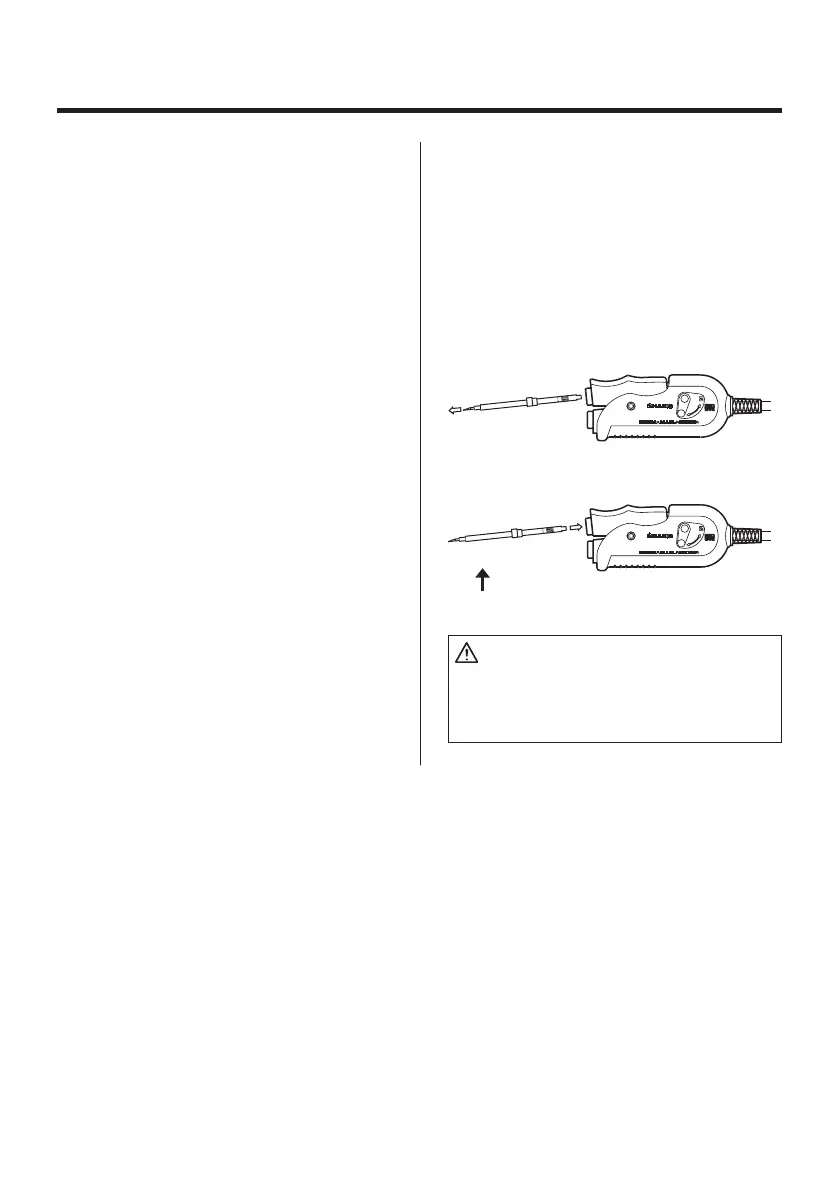

Removing the tip:

Hold the handle and pull the tip out of the

handpiece with the heat resistant pad.

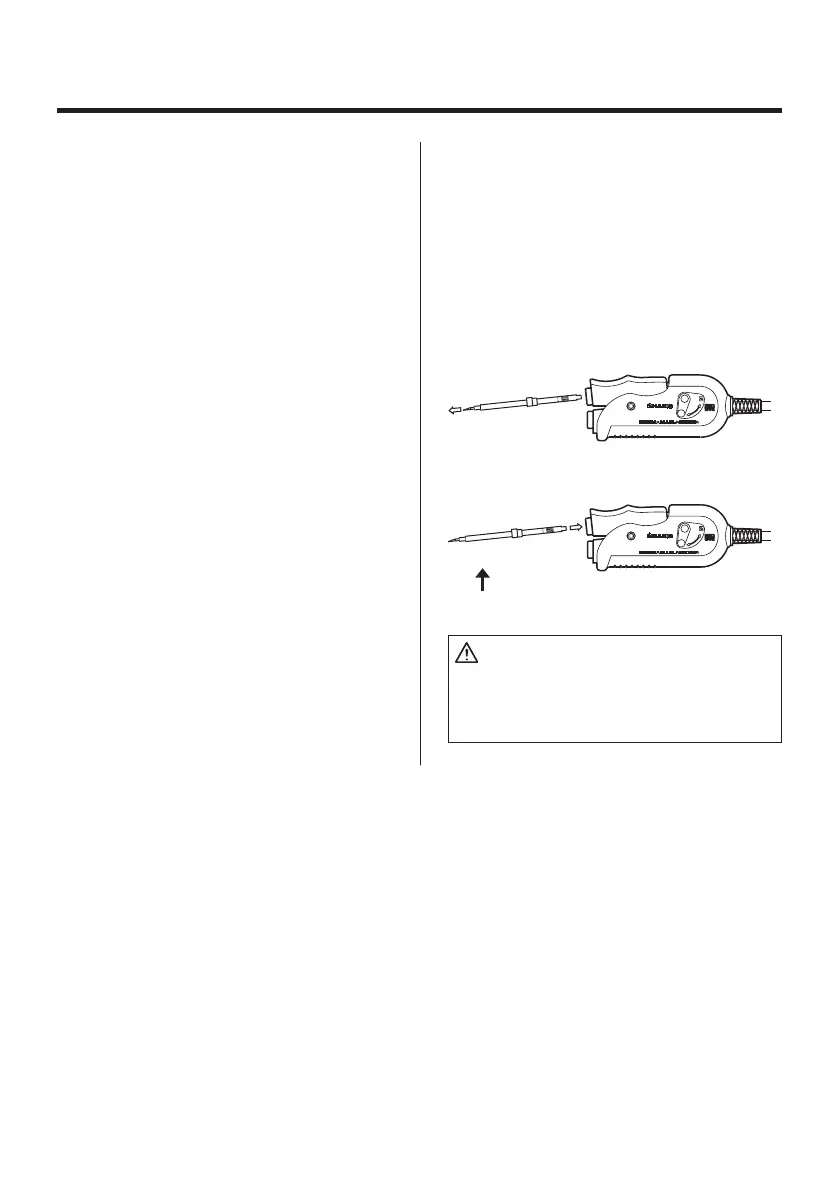

Inserting the tip:

Before inserting the tip; Insert the Tip ID

number key into the process gate until the

buzzer sounds once.

Hold head part and insert the tip into the

handpiece. Push until the tip stops.

CAUTION:

The tip can be very HOT. Use the heat resis

-

tant pad for handling hot tips, but do not hold

the hot portion of the tip, even with the pad,

for longer than necessary.

5

6. When the set temperature is reached,

the buzzer sounds and the heater lamp

at the lower right of the temperature

display starts blinking.

NOTE:

Once the two tips are inserted into the hand-

piece, heat control begins.

Both tips of the set must be inserted or the

handpiece will not heat.

CAUTION:

Never set the temperature to any value over

400°C (750°F). Doing so may damage the

station. Set the temperature according to the

type of work to be done.

●

Operating instructions

1. Set the Temperature

2. Switch lever on the handle

The FM-2023 is double acting.

• When the tips are touching - i.e. the

handpiece is closed- an ʻRʼ is visible on

the handle. Operate by squeezing the

movable part of the handle at the back.

• When the handpiece is open, an ʻNʼ

is visible on the handle. Operate by

squeezing the movable part of the

handle at the front.

3. Apply solder or flux

If there is insufficient solder on the PWB,

or the soldered area is too small, apply

solder or flux to the PWB. Solder may

also be applied to the tips.

4. Melt the solder

Place the tips on the soldered part and

melt the solder. Confirm that the solder is

fully melted. See sketch ʻAʼ.

5. Remove the component

After confirming that the solder is fully

melted, lightly squeeze the handpiece to

grasp the component and lift to remove

the component. See sketch ʻBʼ.

CAUTION:

Very high tip temperatures may damage the

printed circuit board, possibly causing the

printed pattern to become detached. HAKKO

recommends setting the tip temperature be

-

low 300°C (572°F) for all normal work. Using

the lowest possible effective temperature not

only helps protect parts that are sensitive to

heat, it also helps protect the tip from deterio-

ration caused by heat.

Loading...

Loading...