45

Introduction

3 Introduction

3.1 Requirements

❙ HAMEG HM8118 LCR measuring bridge with rmware

from 1.37 upwards.

❙ HZ184 Kelvin measurement cables

❙ 1 x HAMEG 1,000 µF capacitor (not contained in

shipment)

❙ 1 x HAMEG 280 µH inductor (not contained in shipment)

❙ 1 x HAMEG 100 kΩ resistor (not contained in shipment).

First connect the HZ184 cables supplied to the HM8118.

The two plugs of the black cable are connected to the ter-

minals LCUR and LPOT, the plugs of the red cable to the

terminals HCUR and HPOT.

After turning the instrument on, the rst steps are the open

circuit and the short circuit calibration procedures at the

preselected frequency of 1.0 kHz because the measure-

ment cables HZ184, in conjunction with the terminals, due

to their design, show a stray capacity, a residual induc-

tance and a residual resistance which impair the accuracy

of the measurement results. In order to minimize these in-

uences, the compensation of impedance measurement

errors caused by adapters and cables is necessary.

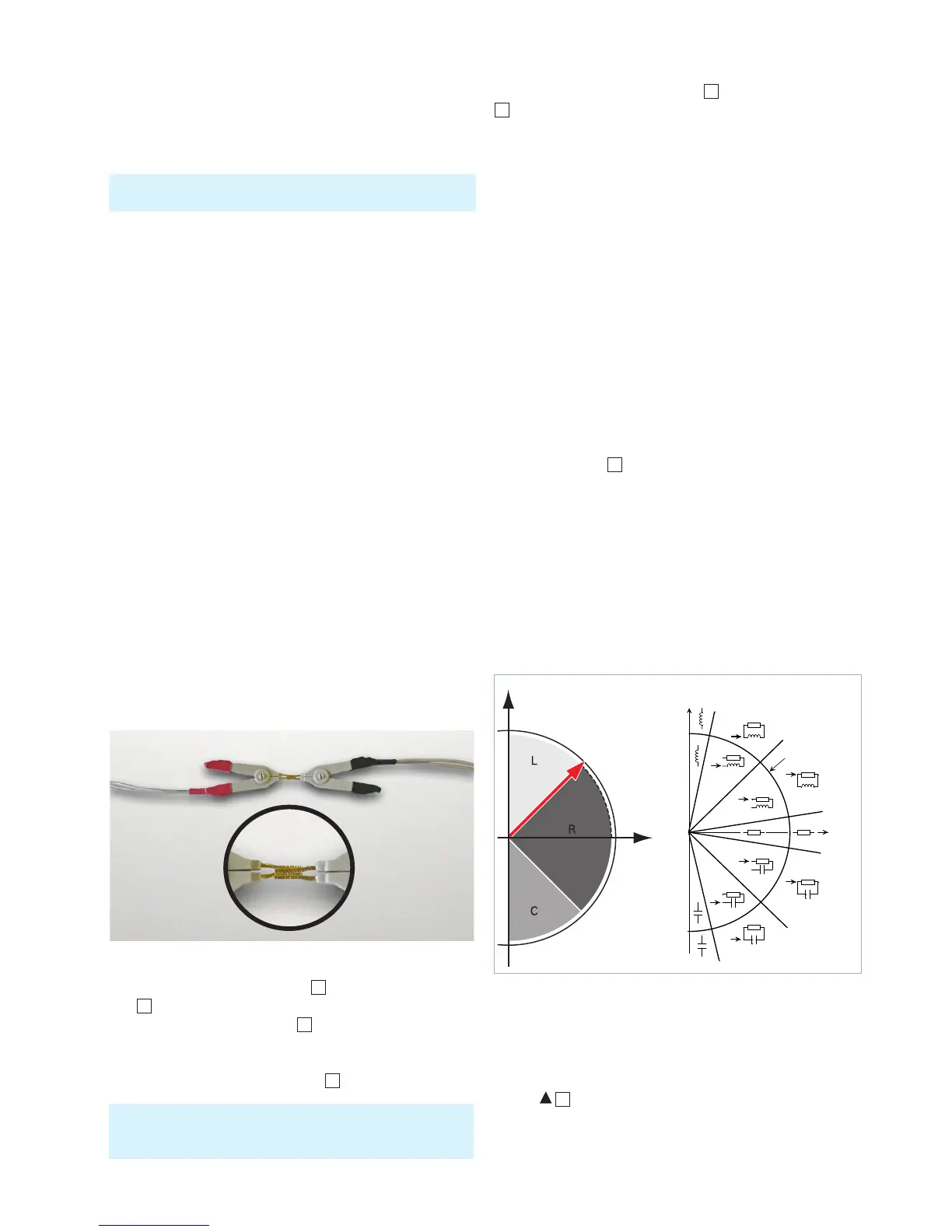

For the open circuit calibration, position the two clips apart

from each other. For the short circuit calibration connect

both clips as shown in Fig. 3.1.

Push the button MENU/SELECT

3

and then the button

C-D

34

in order to enter the CORR menu. Select the menu

item MODE and use the knob

6

to change the menu entry

from SGL to ALL in order to automatically perform the cali-

bration at all 69 frequency steps provided. Leave the menu

by pushing the button MENU/ESC

5

.

The following components are only intended to be used as an ex-

ample for a quick introduction to the instrument.

Fig. 3.1: Short circuit calibration with HZ184.

The mode SGL is used to only calibrate at the presently selected

frequency; this procedure takes just a few seconds and is desti-

ned for measurements in one or a few frequency ranges only.

Now start the open and short circuit calibrations by

pushing the buttons ZERO/OPEN

11

resp. ZERO/SHORT

12

. The instrument will now determine correction factors

at all 69 frequency steps valid for the presently connected

measurement cables and store them until the instrument is

switched off. This procedure will last appr. 2 minutes.

3.2 Measurement of a capacitor

Now connect the capacitor to the terminals of the HZ184.

Please observe the polarity of the capacitor and connect

the black terminal to the negative terminal of the capacitor,

marked with a – (minus).

As the instrument is set to automatic mode, the measure-

ment function will be automatically switched to function

no. 3 (C-D). Because the measuring frequency of 1.0 kHz

was preselected, the capacitor will not be measured in its

regular operating mode, so the value displayed of appr.

900 µF will not equal the specied value of 1,000 µF.

Change the measuring frequency to 50 Hz by pushing the

button SET/FREQ

8

and turning the knob until 50 Hz are

shown on the display. Now the value displayed will change

to appr.1,000 µF depending on its tolerance. The dissipa-

tion factor „D“ will be very low at this setting.

The smaller the loss angle, the more the real world com-

ponents will come close to the ideal. An ideal inductor has

a loss angle of zero degrees. An ideal capacitor also has

a loss angle of zero degrees. An ideal electrical resistor,

however, has a loss angle of 90 degrees, it has no capaci-

tive or inductive components.

3.3 Measurement of an inductor

Before you connect the choke, increase the measuring fre-

quency by one decade to 500 Hz by pushing the arrow

button

7

above the knob. Disconnect the capacitor and

connect the choke to the terminals of the HZ184.

The instrument will now automatically switch to the func-

tion no. 1 (L-Q) and the inductance of the choke will be dis-

applied on the red terminal. The bias voltage works only

when the instrument on capacitance measurement

mode.

Measuring function selection

The desired test function is selected by push buttons (12)

and (14). The push button (12) gives access to the main

parameter (R, L or C), The push button (14) allows a

secondary parameter measurement (Q/D, impedance or

phase).

In order to measure D parameter the instrument needs at

first to be set to capacitance measurement mode, on the

other way, Q parameter will be displayed.

Auto-measurement function

The HM

8018-2 is able to automatically determine the

component type in most cases. 3 different automatisms

exists: the automatic impedance range selection (see the

section « Auto-ranging»), the automatic mode

(series/parallel) selection (see the section « passive

components »), and the automatic function selection. These

three automatisms are simultaneously activated when the

instrument is set in automatic mode with the RANGE

AUTO key (7). Then the user can change function or mode

that disables their respective automatism. The manual range

selection disables the three automatisms.

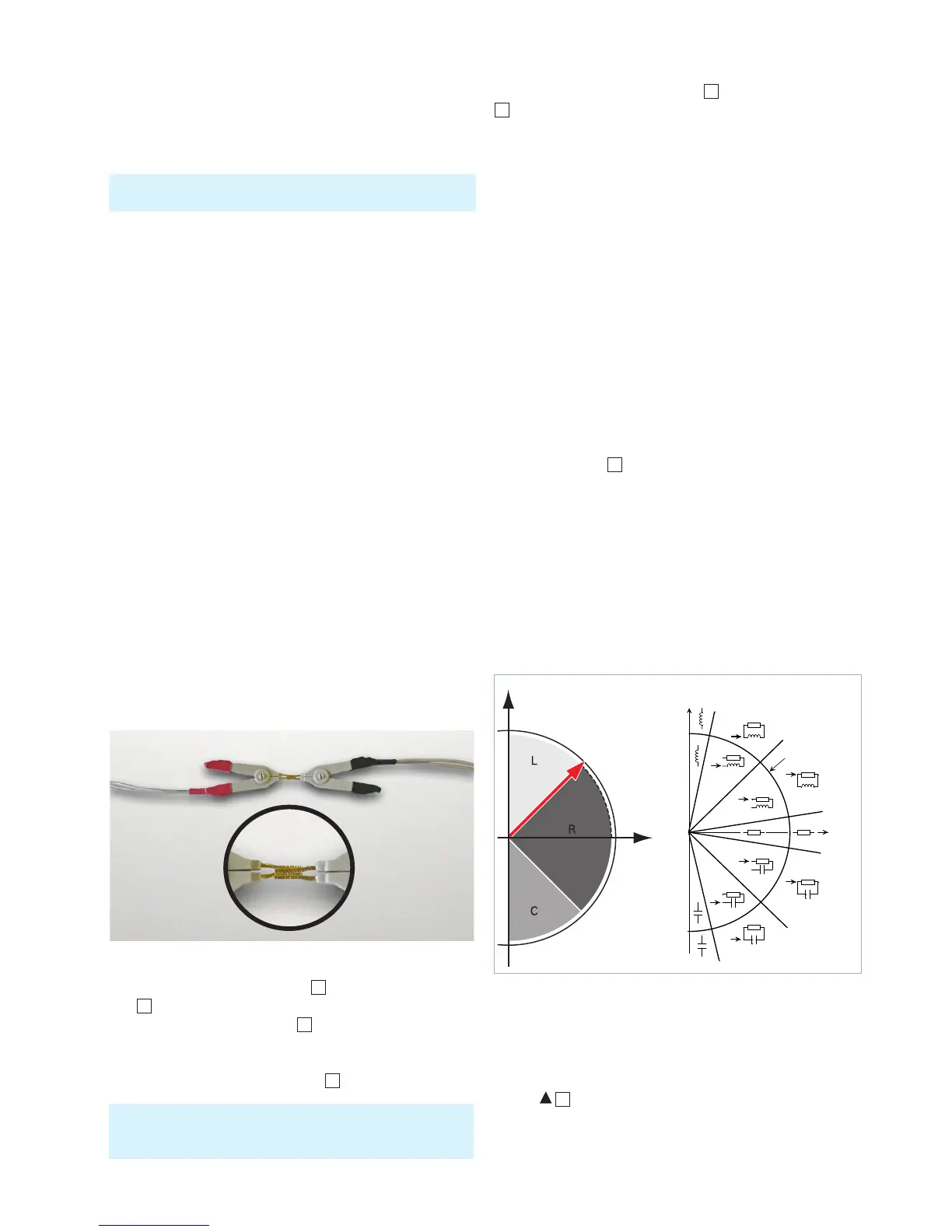

When the instrument is on automatic mode the function

choice depends on the impedance module, phase angle as

well as the quality factor .The diagram below shows the

choice made by the instrument.

Calculation functions

Ap

art from displaying normal values as resistance, inductance or

capacitance, the HM8018-2 can display relative deviations and

percentages. It is not possible to use these calculation modes for

other functions than the three previous values. The deviations

and percentages are displayed in relation to the two stored values

A and B.

The procedure to obtain relative measurement is as follows:

1) Connect the component corresponding to the reference

value.

2) Store the value (memory A) by pressing on the STORE key,

then press the A key.

3) Press on the A key. The indicator -A lights up and the

display shows the value (Measure – A).

A direct percentage measurement is possible, it is only to use the

÷B key instead of the –A key in the previous procedure. Then the

instrument displays the value 100*Measure/B in %.

To obtain a deviation in % proceed as follows:

1) Connect the component corresponding to the reference

value.

Loading...

Loading...