26

PART 4. VENTING

3. If practical, close all building

doors, windows and all doors

between the space in which the

appliance remains connected

to the common venting system

and other spaces in the building.

Turn on clothes dryers and any

appliances not connected to the

common venting system. Turn on

any exhaust fans, such as range

hoods and bathroom exhausts, at

maximum speed. Do not operate

a summer exhaust fan. Close all

fireplace dampers.

4. Place the appliance being

inspected in operation. Follow

the lighting instructions. Adjust

the thermostat so the appliance

will operate continuously.

5. Test for spillage at the draft hood

relief opening after 5 minutes of

main burner operation. Use the

flame of a match or candle or

smoke from a cigarette.

6. After it has been determined

that each appliance remaining

connected to common venting

system properly vents when

tested as outlined, return

doors, windows, exhaust fans,

fireplace dampers and any other

gas burning appliance to their

previous condition of use.

7. Any improper operation of the

common venting system should

be corrected so the installation

conforms with the National

Fuel Gas Code, ANSI Z223.1.

When resizing any portion of

the common venting system,

the common venting system

should be resized to approach

the minimum size as determined

using the appropriate tables in

Appendix G in the National Fuel

Gas Code, ANSI Z 223.1

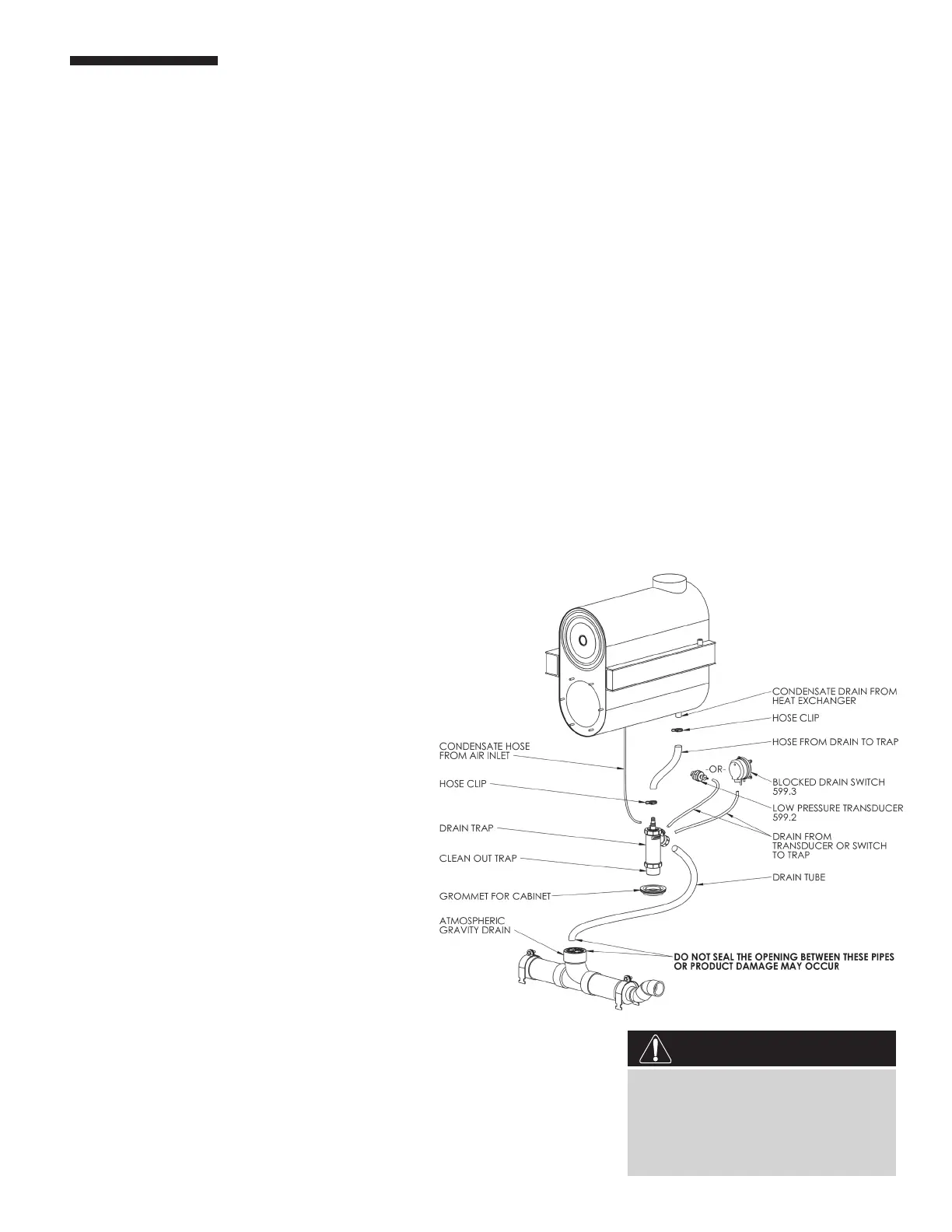

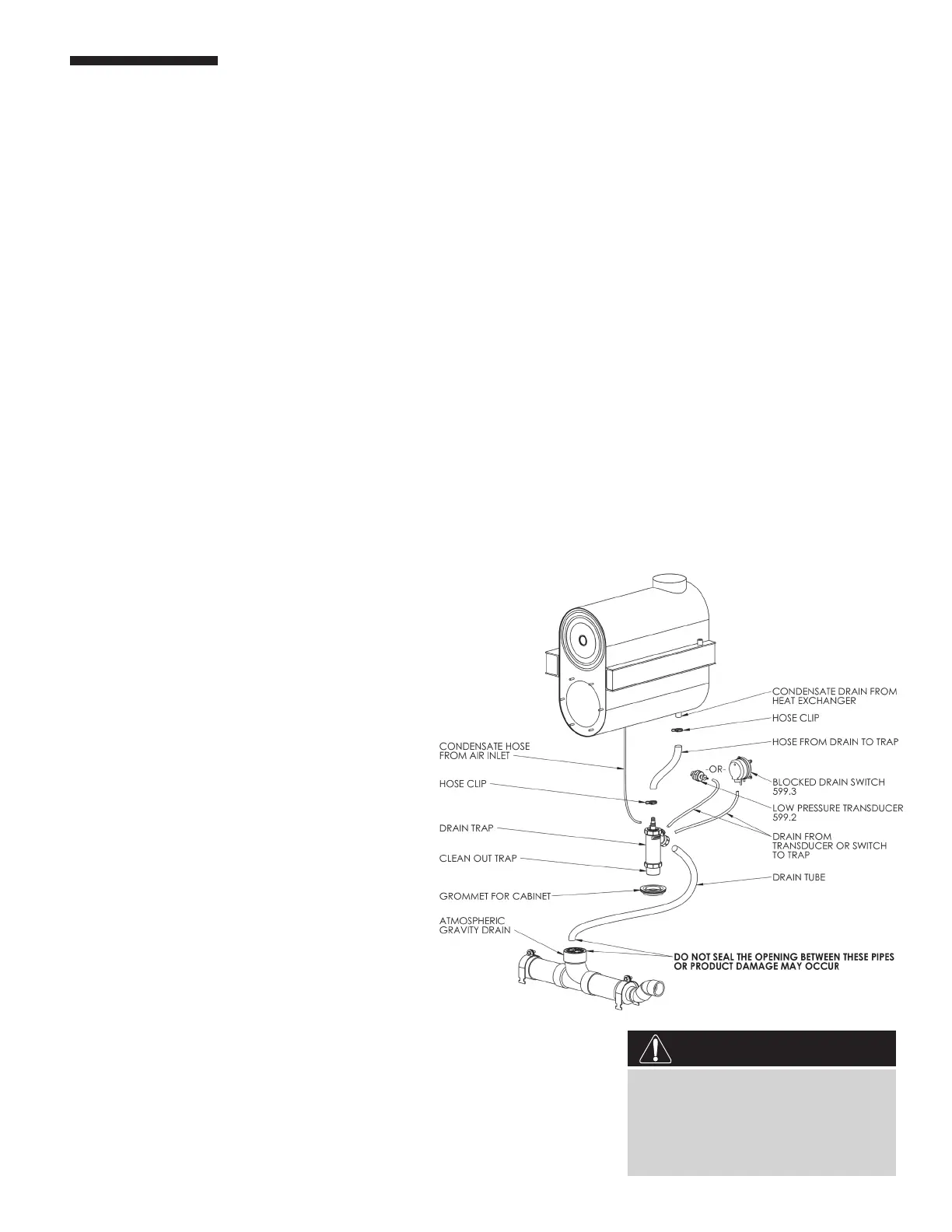

F. CONDENSATE REQUIREMENTS

This is a condensing high eciency appliance,

therefore this unit has a condensate removal

system. Condensate is nothing more than water

vapor derived from the combustion products,

similar to an automobile when it is initially

started. This condensate does have a low pH and

should be treated with a Condensate Neutralizer

Filter. This filter contains either lime or marble

rocks, which will neutralize the condensate. The

outlet of the filter is sized for 1.5" PVC pipe. It

is very important that the condensate line

is sloped away from and down to a suitable

inside drain. A condensate neutralizer and a

condensate pump kit are available from Hamilton

Engineering Co, Inc. It is also very important

that the condensate line is not exposed to

freezing temperatures, or any other type of

blockage. Plastic tubing or PVC pipe should be

the only materials used for the condensate line.

Steel, brass, copper or others will be subject to

corrosion and deterioration. A second vent may be necessary to prevent

condensate line vacuum lock if a long horizontal run is used. The EVO

appliance has an automatic safety device that will shut it down in the

event of a condensate drain blockage. Please test annually.

Maximum volume of condensate produced is 11 gallons per hour per

1,000,000 BTU of gas burned.

E. HEATER REMOVAL FROM AN EXISTING COMMON VENT SYSTEM (continued)

NOTE: Heat

exchanger

MUST be level or

pitched slightly

to the rear!

In a common vent system, DO NOT POWER

THE UNIT OFF! Equipment damage may

occur. To disable operation, turn o gas,

NOT power. If you have any questions,

please call Hamilton Engineering Technical

Support at 800.968.5530.

WARNING

FIGURE 47

CONDENSATE DRAIN DETAIL

Loading...

Loading...