-20-

LUBRICATION GUIDE

GREASE FITTINGS

There numerous grease ttings on the rake. If equipped with a center kicker wheel, there will be one

more on the pivot point. Lubricating properly and often enough will prolong the life of your rake. Grease

daily during normal use and before and after storage and after power washing. Use a good grade of

high-quality grease. Make sure that grease comes out around the shaft on sleeve-type bearings. Wipe o

excessive grease to prevent accumulation of cha or grit around the bearing.

Location

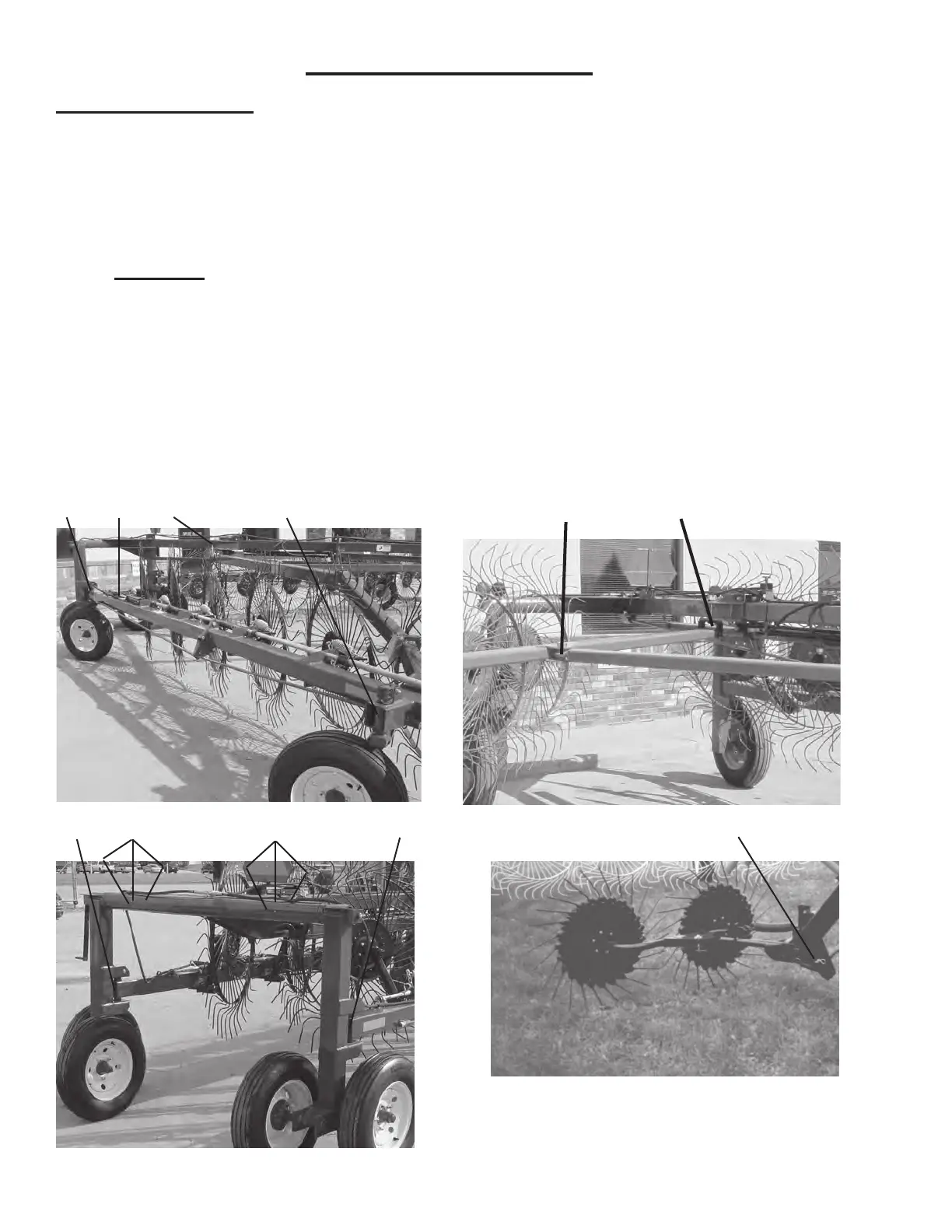

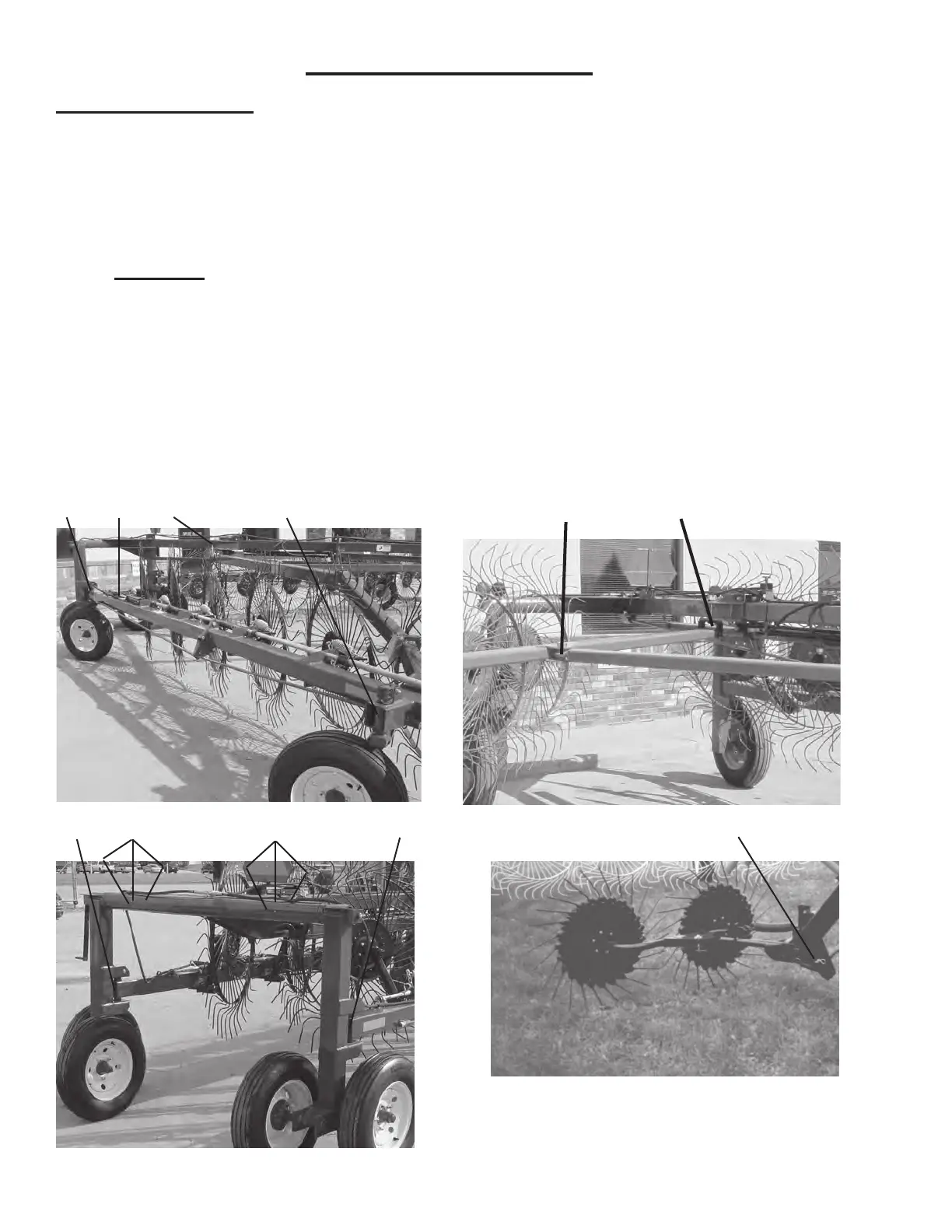

Listed and shown are the description of location and number of grease ttings.

A. (2) Top Opening Arm Front Pivot

B. (2) One on Each Gauge Wheel

C. (2) One on Each Lift Cylinder Mounting Bracket

D. (2) One on Each Rake Beam Pivot

E. (6) Top Rear Windrow Width Adjustment

F. (5) Top Opening Arm Rear Pivot

G. (1) Center Kicker Wheel Pivots (If Equipped)

(4) One on Each Transport Wheel Hub (4 on BF12HC and 6 on BF14HC)

(12) One on Each Rake Arm Hub (BF12HC Only)

D

DEE GD

C F B

A F

Loading...

Loading...