Maintenance

Maintain the chipper with care and keep it clean at all times.

To service or inspect the equipment, or to change an accessory, you must:

✓ Switch the engine off

✓ Allow the chipper to cool before any inspections or adjustments

✓ Wait until the cutting rotor and engine are at a complete standstill before opening the

cutting rotor housing

✓ Disconnect the spark plug wire from the spark plug

✓ Switch the fuel lever to the off position

Initially after 2 working hours:

✓ Check for any loose nuts and bolts

✓ Check belt tension (refer to belt tension section)

The belt will stretch when it is new

✓ Grease the rotor bearing

One or two pumps are sufficient

Be careful not to over grease

The bearing is already greased when the equipment is new

Use bearing grease or all-purpose grease

Every 20 working hours:

✓ Check for any loose nuts and bolts

✓ Check belt tension (refer to belt tension section)

✓ Grease the bearing as above, be careful not to over grease

✓ Check sharpness of knives

✓ Check condition of the belt guard

A damaged guard must be replaced by an identical or equivalent guard immediately

It is recommended to contact Hansa for a replacement guard.

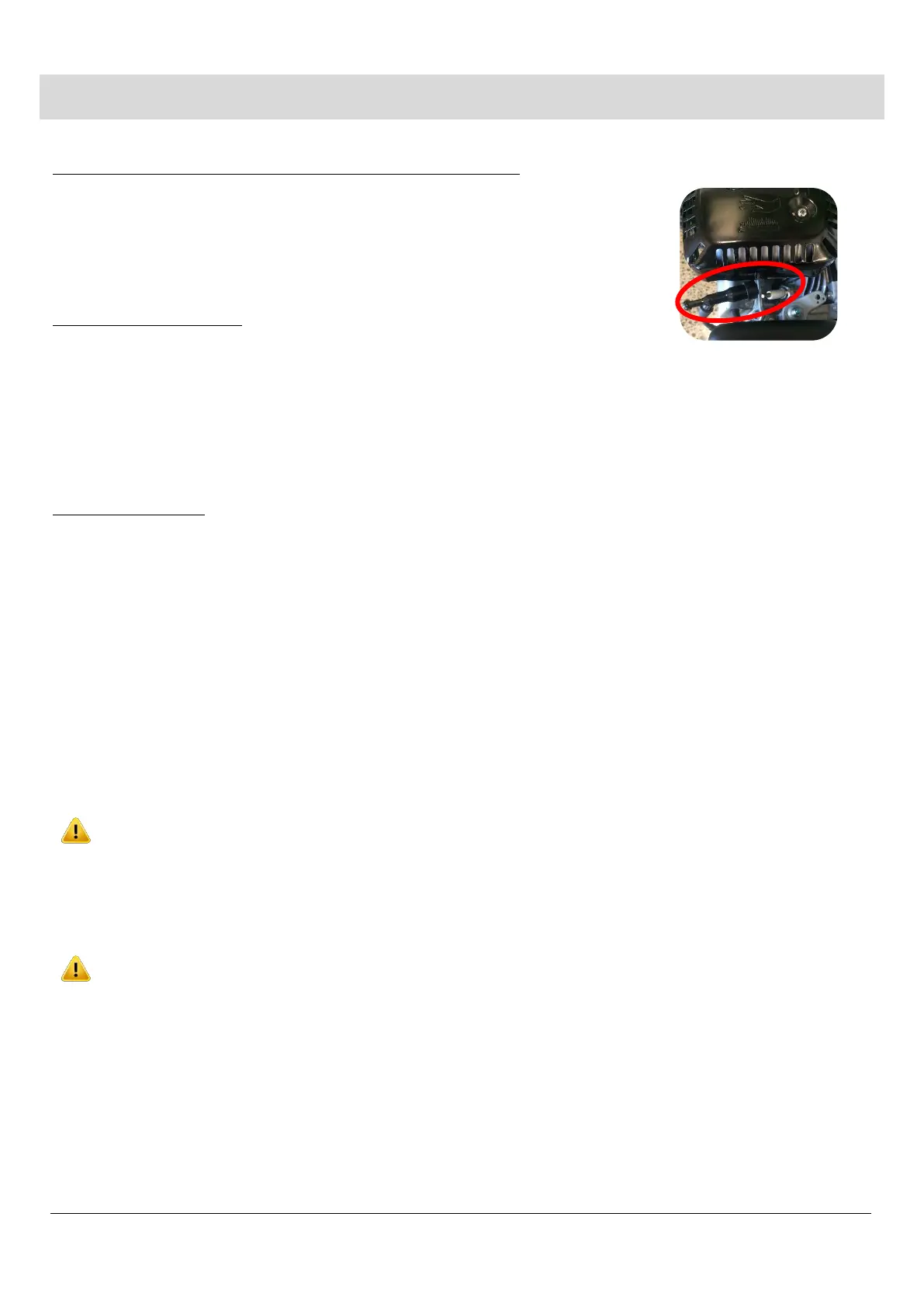

Knife re-sharpening and knife replacement

How do I know that the knives need re-sharpening?

Chipper loses its self-feeding action with blunt knives

Material has to be pushed in

Material comes out in long strips

How to re-sharpen the knives:

If you don’t have a surface grinder or are unsure how to re-sharpen the knives, contact a professional saw doctor or Hansa to

arrange re-sharpening.

Tools and materials required for re-sharpening (approx. 40 mins):

• 2 x 13 mm spanners

• 2 x 16 mm spanners

• 6 mm hexagonal Allen key

• Nylon hammer (recommended)

• Surface grinder

• Coolant

Loading...

Loading...