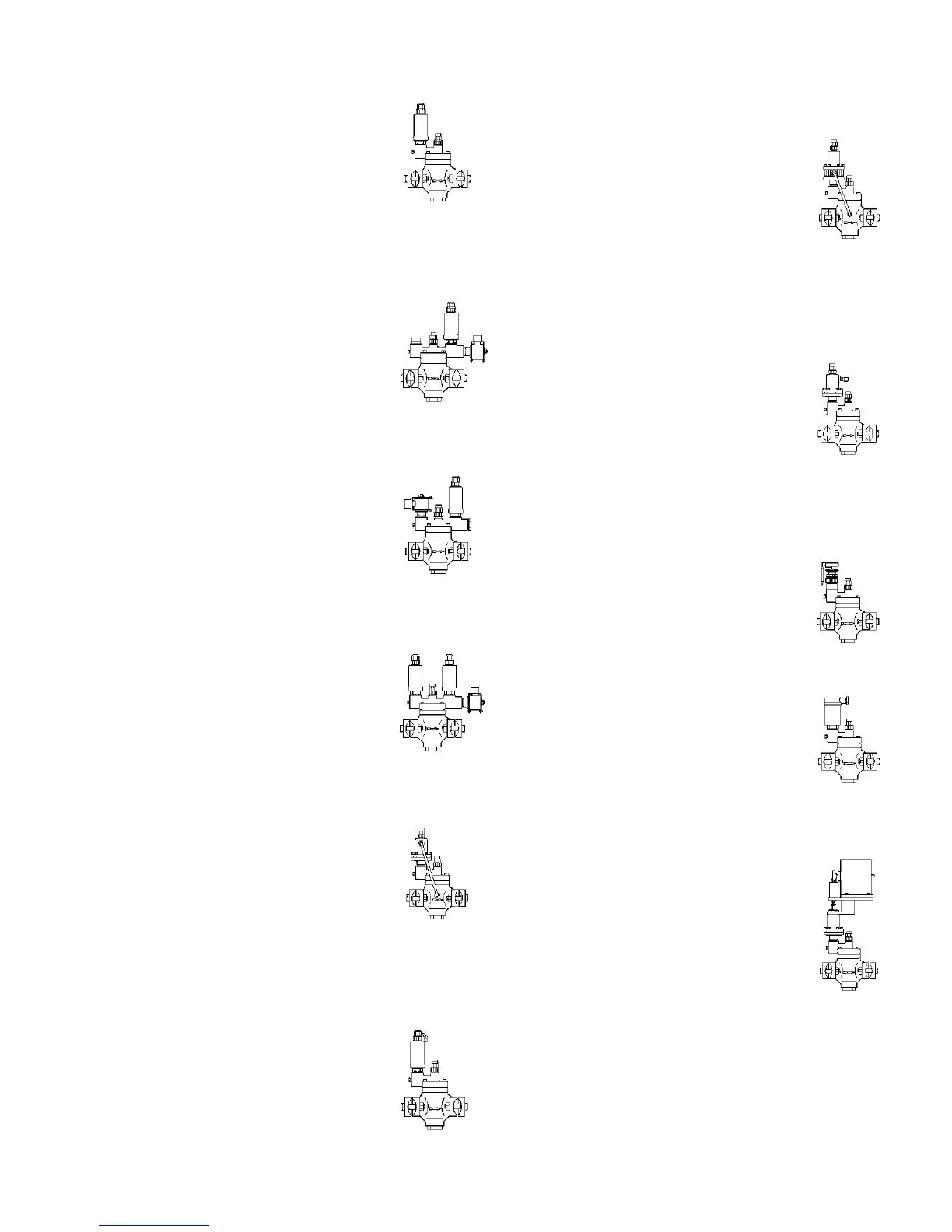

REGULATOR VARIATIONS

HA4A STANDARD REGULATOR

This most common pressure regulator

modulates to control evaporator

pressure, condensing pressure,

pressure in a vessel, or pressure in a

portion of a system. It is frequently

called an evaporator pressure regulator

(EPR) or back pressure regulator. Opens

on rising inlet pressure. See page 10.

Shown with M3W pilot.

HA4AS REGULATOR WITH

ELECTRIC SHUT-OFF

This control is commonly used for

temperature control or defrost.

Regulates at the set-for pressure when

energized. When de-energized, the valve

closes tight regardless of the pressure

setting. See page 11.

HA4AB REGULATOR WITH

ELECTRIC WIDE OPENING

Commonly regulates for defrost or

temperature, but opens wide for

maximum cooling. Regulating at the set-

for pressure when de-energized;

regulator opens when energized. See

page 11.

HA4AD DUAL PRESSURE

REGULATOR

Regulates (evaporator) pressure at a

setting when energized, and at a higher

setting for defrost, temperature control,

or pressure relief when de-energized.

See page 11.

HA4AL DIFFERENTIAL

PRESSURE REGULATOR

Commonly used as liquid pump relief,

condenser-receiver pressure difference

control, discharge pressure boosting for

defrosting or heat recovery, and other

similar applications. This control

modulates to maintain the set-for

difference between inlet and outlet

pressure. See page 10.

HA4AK RESEATING

RELIEF REGULATOR

Used for defrost, high-to- low side relief,

or nonatmosphere relief to other parts of

the system. This control opens when

system upstream pressure is above the

tagged and sealed set point pressure,

and repeatedly reseats after operation.

See page 10.

HA4A

HA4AS

HA4AB

HA4AD

HA4AL

HA4AK

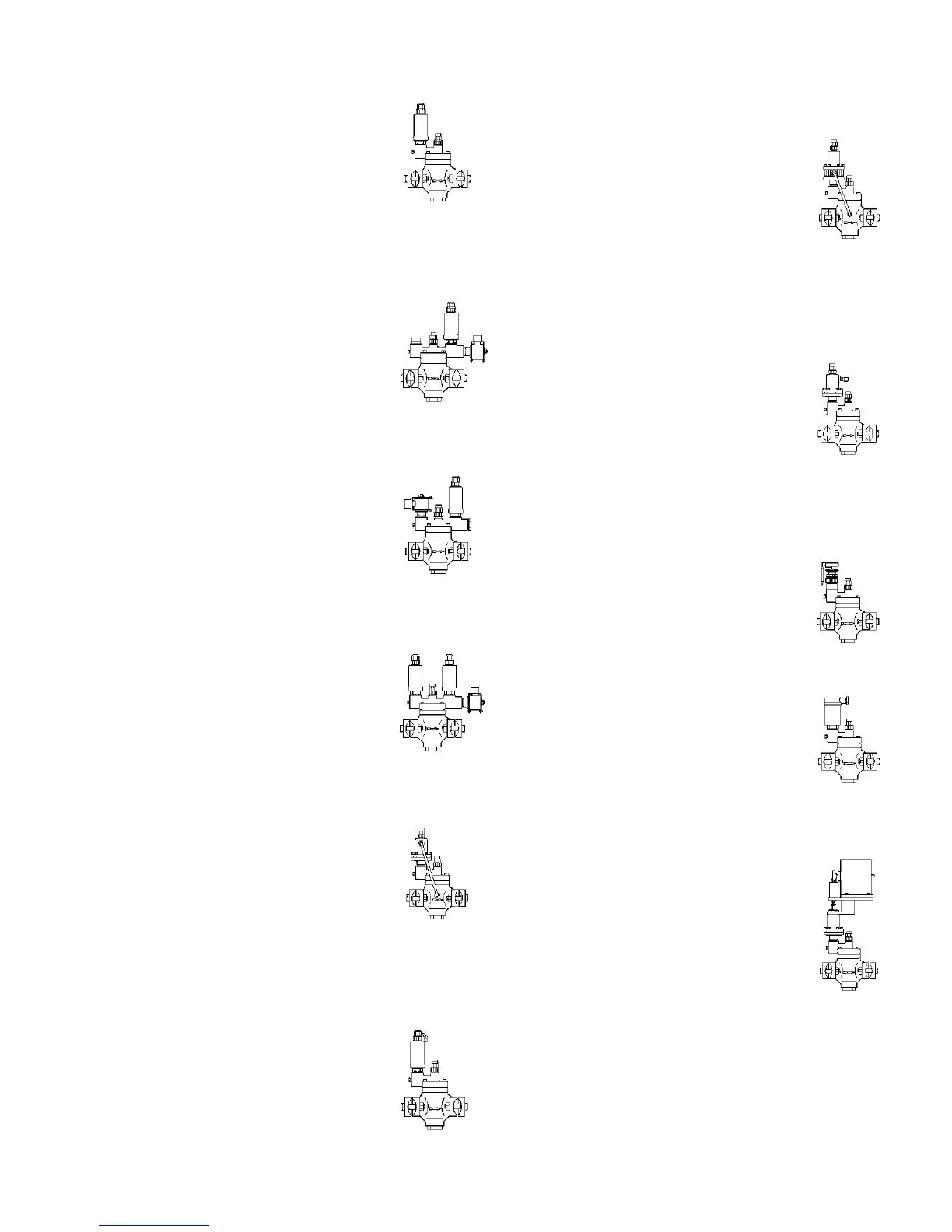

Controls outlet pressure by opening

as downstream pressure falls below

the set point. Used for hot gas to

provide artificial refrigeration loading,

for condenser and receiver pressure

control by means of gas bypass,

limiting hot gas pressure supply in

defrosting evaporator in conjunction

with liquid drain traps, or

compressor suction pressure limitation.

Can be combined with electric shut-off,

temperature-operated, dual, or wide-

opening features. See page 11.

Commonly used for precise air or liquid

controller. An air, vapor, or liquid

pressure signal to the control module

bonnet increases inlet pressure from

the set-for pressure value at a 1:1 ratio.

The vapor pressure capillary tubing

and bulb system modulates the

increases to control air or liquid

temperature. See page 12.

Electronic pilot and controller provides

very precise temperature control of

various cooled media under fluctuating

load conditions. See page 12.

Commonly used for precise room

temperature control or liquid chiller

control. The controlling motor changes

HA4AM

NOTE: Many other control functions can be achieved

by combining the control modules in different

arrangements. For example: a dual regulator with

electronic pilot and secondary relief pilot; i.e. HA4ADJ.

Loading...

Loading...