6.7. LUBRICATION AFTER INSTALLATION

After levelling, alignment and securing, the gear unit must be lubricated. All instructions mentioned in

chapter 7 "LUBRICATION" must be followed up.

If a long period of standstill is expected before starting up the gear unit, the instructions mentioned in

paragraph 12.6 "EXTENDED PERIODES OF STANDSTILL" must be followed up.

7. LUBRICATION

Lubrication serves four main functions :

- prevents metal to metal contact in gears and bearings

- reduces friction losses

- dissipates the generated heat from gears and bearings

- prevents corrosion

Different lubrication systems can be used, depending on

- gear velocity

- gear unit mounting position

- operating conditions

Hansen Industrial Gearboxes use one of following systems :

- splash lubrication

- forced feed lubrication: - circulation lubrication

- pressure lubrication

These systems can be completed with auxiliary cooling in different forms (see chapter 9: "COOLING").

ENGLISH

26

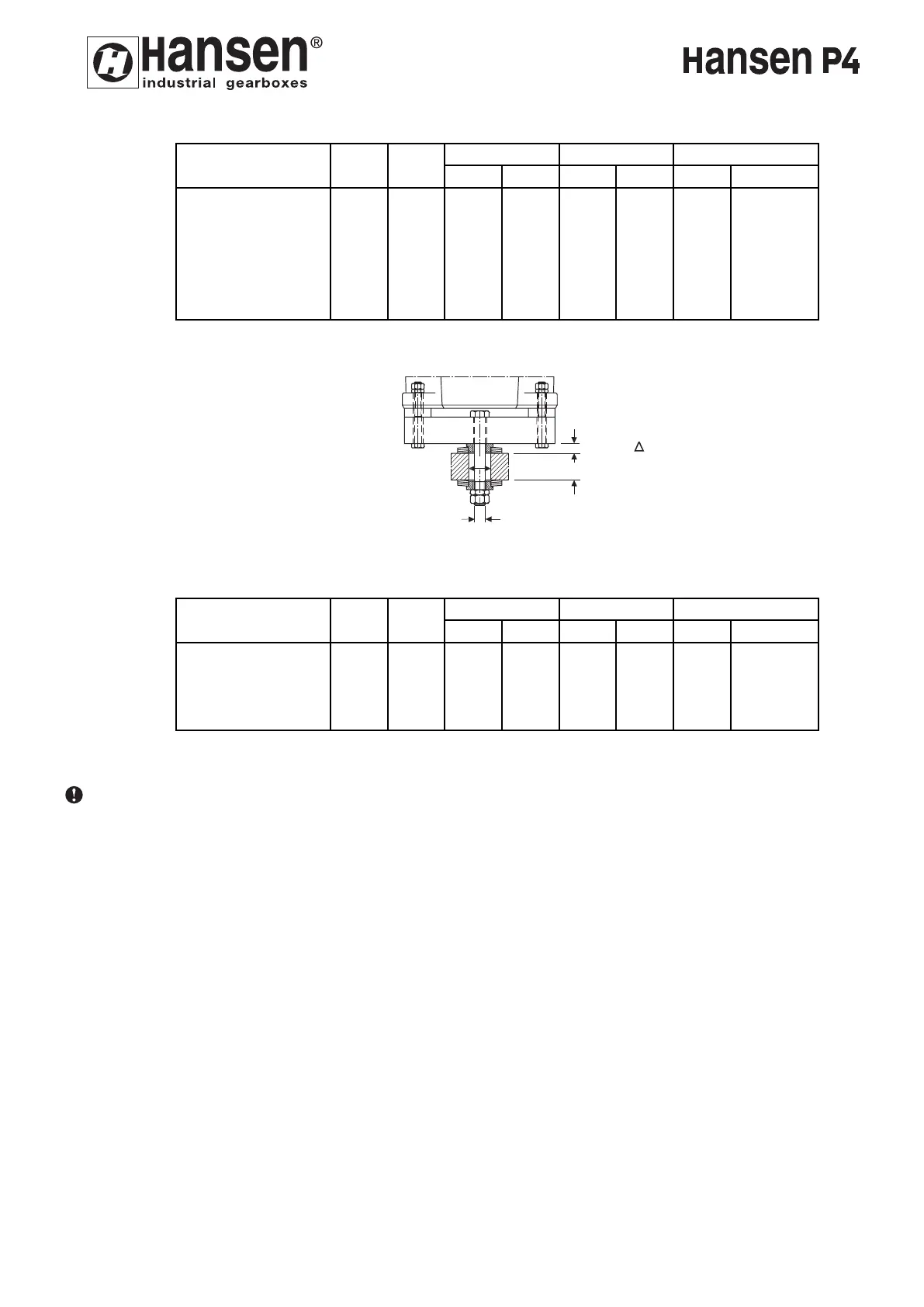

Table 3

Gear unit D PT PR max

ΔΔ

ΔΔ

S A

size

QH.C3

±5

35 M20

mm

50

inch

1.97

mm

0,7

inch

0.028

Q*

2 x 3

DIN 2093

A 80

QH.D3 - QH.D4

QH.E3 - QH.E4

QH.F3 - QH.F4

QH.G3 - QH.G4

45

45

M24

M24

60

60

M30

M36

60

60

2.36

2.36

75

90

2.95

3.54

0,9

0,9

0.035

0.035

1,0

1,0

0.039

0.039

2 x 2

2 x 3

A 100

A 100

2 x 2

2 x 3

A 125

A 125

QH.H3 - QH.H4 60 M36 90 3.54 1,0 0.039

Q*: number of disc s

prings

2 x 3 A 125

S

1

= S - S

PR

PT

D

FIG.3d

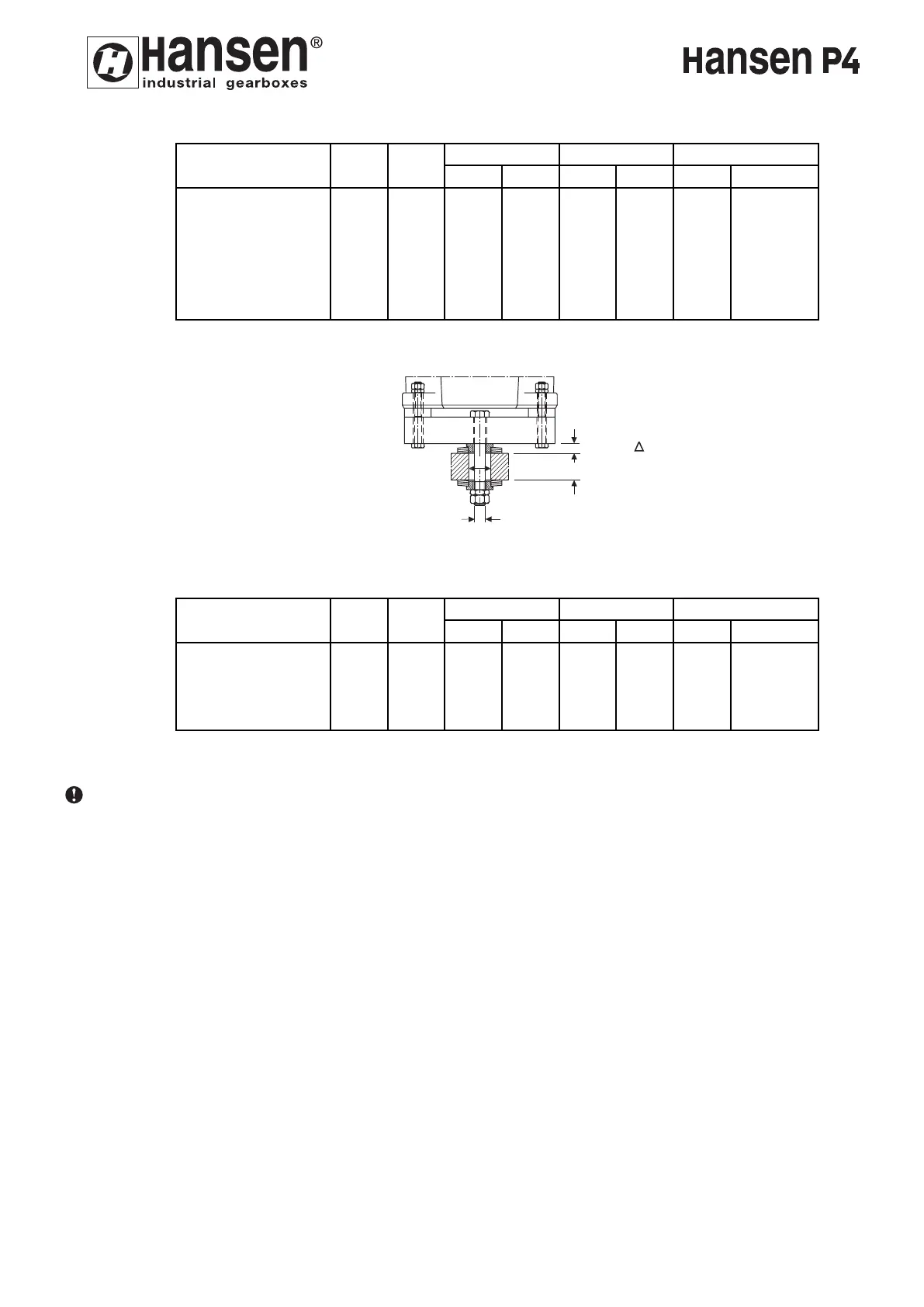

Table 4

Gear unit D PT PR max ΔΔ

ΔΔ

S A

size

QH.J3 - QH.J4

±5

80 M42

mm

105

inch

4.1

mm

1,4

inch

0.055

Q*

2 x 3

DIN 2093

A 160

QH.K3 - QH.K4

QH.L3 - QH.L4

QH.M3 - QH.M4

80

80

M42

M48

80 M48

105

120

4.1

4.7

120 4.7

1,4

1,4

0.055

0.055

1,4 0.055

Q*: number of disc s

rin

s

2 x 3

2 x 4

A 160

A 160

2 x 4 A 160

25

Loading...

Loading...