- After installation and before starting up the gear unit, it is necessary to check that:

- the rotating external parts are provided with adequate protections,

- the gear unit is lubricated,

- the lubricating system , the measuring-, safety- and control instruments, are connected and are

functioning properly,

- the operating and control instruments, the tubes and the flexible pipes are protected against the

harmful external influences,

- the direction of rotation for the gear unit shafts and motor shaft are correct if the gear unit has a

backstop. Refer to the dimensional drawing and paragraph 11.2 “Gear units equipped with a

backstop”.

2.2. GENERAL SPECIFICATIONS

For general specifications such as dimensions, weight, connecting diagrams: refer to the certified drawing of the

gear unit and/or to the Hansen P4 standardized gear unit catalogues.

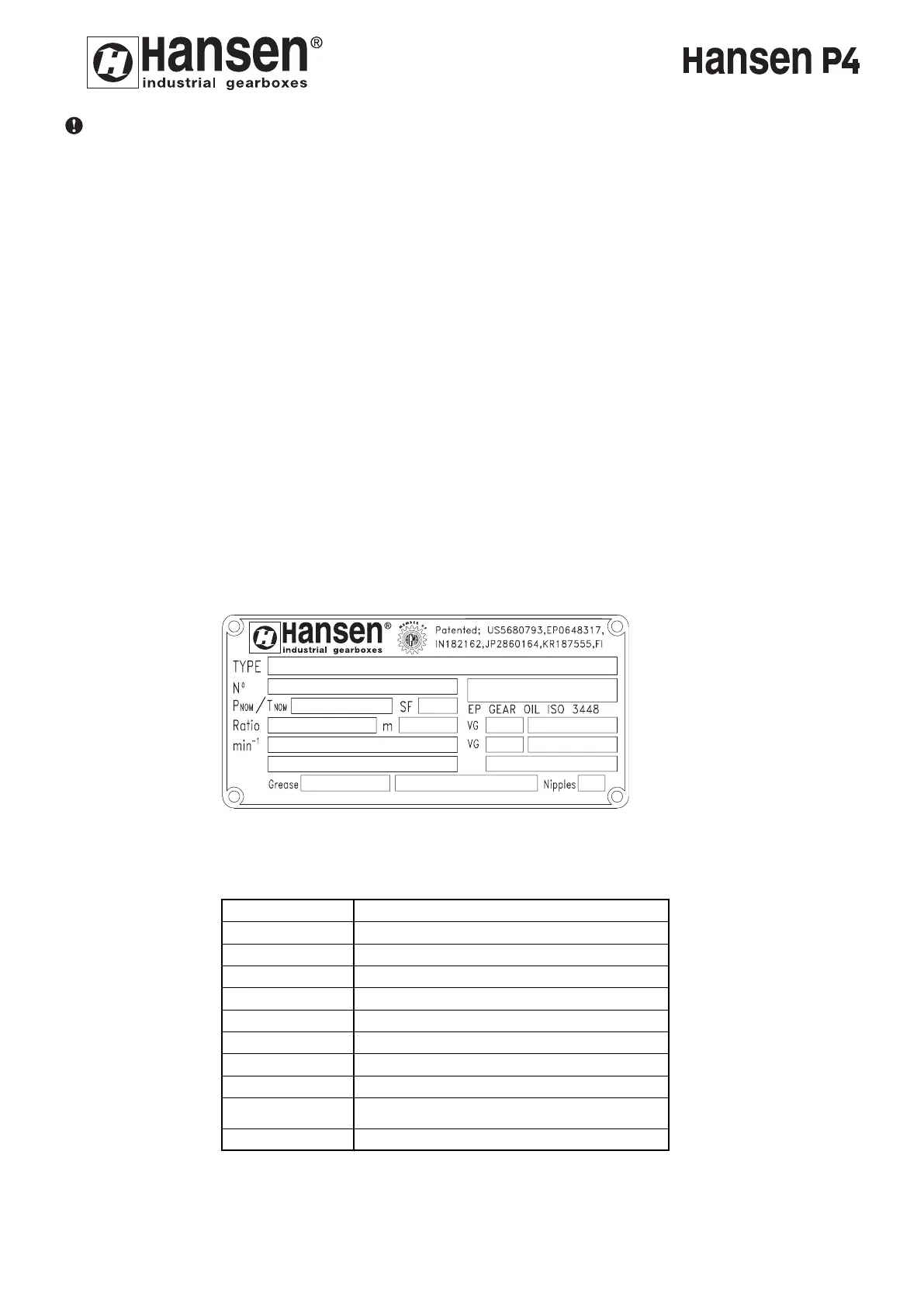

2.3. IDENTIFICATION

Inquiries concerning a gear unit should always specify the unit's complete type code and manufacturing number,

which can be found on the nameplate.

This information is essential to identify the unit supplied by Hansen Industrial Transmissions nv.

The nameplate, which is fitted on each gear unit, also contains information about ratings and/or torque, speed

and lubrication.

Nameplate

Key to symbols

ENGLISH

12

Type

N°

P

NOM

TNOM

SF

min

-1

EP GEAR OIL ISO 3448

VG

*

Grease

Nipples

Type specification of the gear unit (serial number and code)

Gear unit production number

Nominal power rating (kW) at high speed shaft of the gear unit

Nominal torque rating (kNm) at low speed shaft of the gear unit

Service Factor

Input and output speed (speeds)

Gear oil according to ISO 3448

Oil viscosity for a specified ambient temperature range

(possible) Indication of the use of synthetic oil ("Synthetic Oil")

Grease lubrication: grease quantity (indication of grease type

"Q." and brand name, refer to the chapters 12 and 13)

Number of grease points (nipples)

**

**

11

Loading...

Loading...