9.1.2. Oil-to-air coolers

The service manual of the lubrication and cooling system gives detailed information about the oil-to-air cooler.

9.2. ADDITIONAL WATER COOLING

All water cooling systems must be connected to a non-calcareous water supply. See also the service manual on

lubrication and cooling system and/or technical leaflets on specific instrumentation. The use of seawater must be

specified with the order; coolers suited for use of seawater are available.

When the gear unit is not operating and freezing temperatures may occur, the water must be drained from the

cooling system. Drain facilities have to be provided by the end user.

Unless otherwise stipulated, the water flow indicated on the dimensional drawing is the required rate for water at

20°C (70°F).

Depending on the load, the ambient temperature and the water temperature a lower rate can suffice. Adjust the

water flow to obtain an oil temperature during operation between 60 and 80°C (140 and 180°F).

9.2.1. Oil-to-water coolers

Refer to the certified drawing for the connection of the oil-to-water cooler to the coolant supply system.

The service manual of the lubrication and cooling system gives detailed information about the oil-to-water

coolers.

9.2.2. Cooling coils

The direction of the waterflow is optional.

The cooling coils are suited for fresh as well as for seawater.

Maximum allowable water pressure : 0,8 MPa (8 bar, 116 psi).

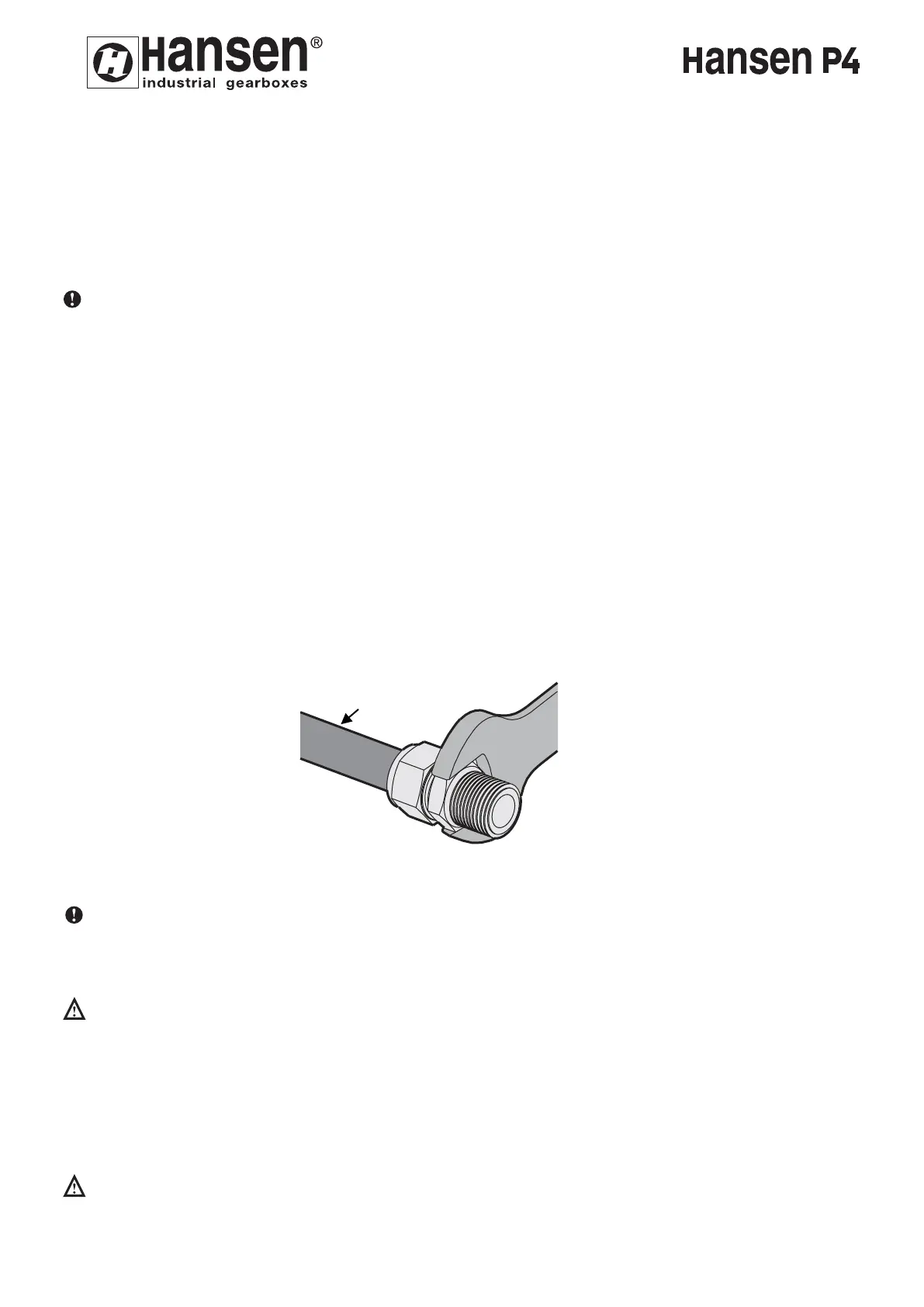

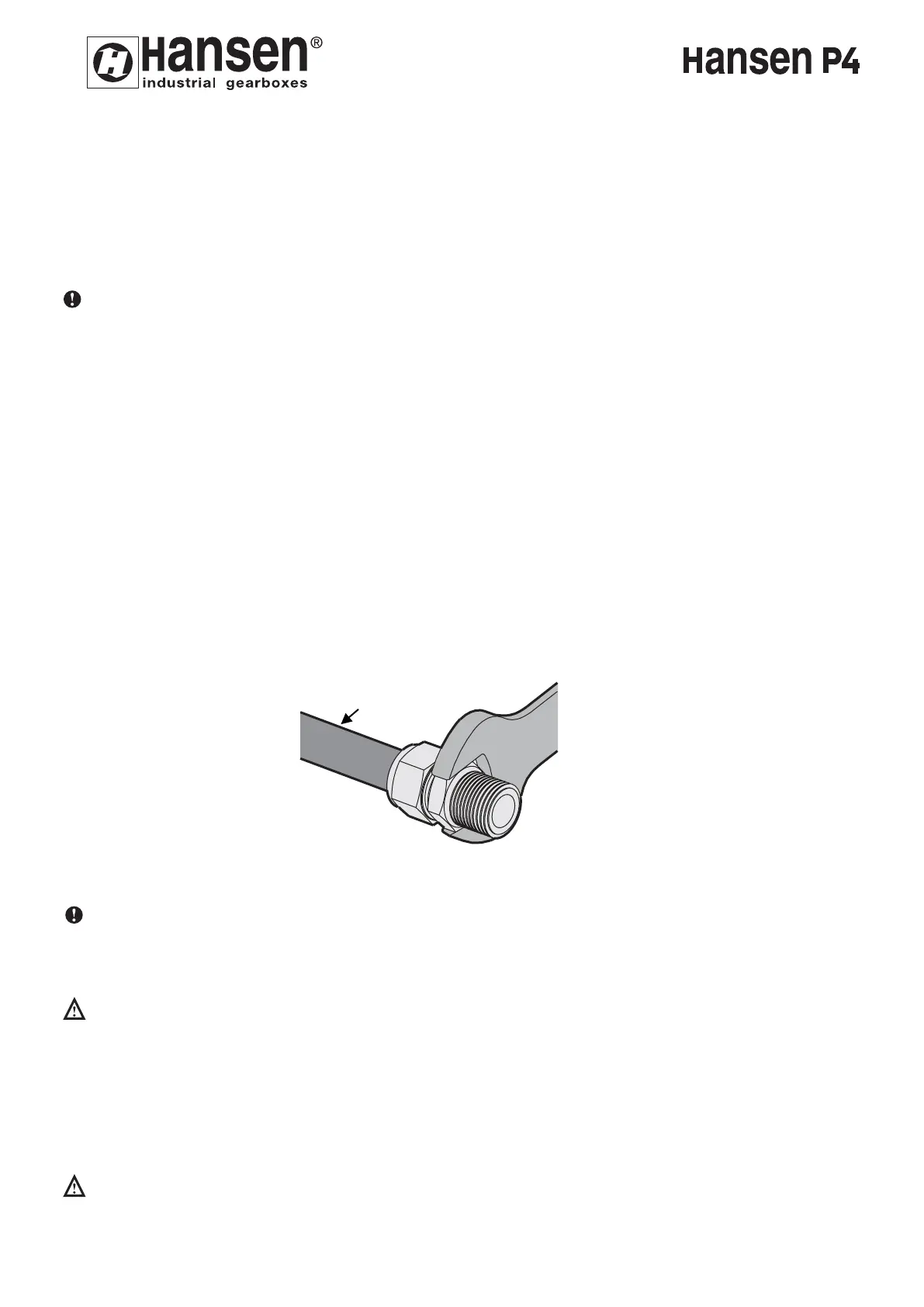

Connection of the cooling coil to the water supply.

Warning: In order to avoid torsioning of the cooling coil, hold the premounted connection with a suitable

wrench as shown in fig. 6.

10. BACKSTOPS

Backstops are subject to wear and must be inspected or replaced at intervals depending on operating conditions.

The customer must take all necessary precautions to prevent that failure of the backstop could cause physical

injury and/or severe damage to the drive and/or application.

The time span between two checks of functioning depends on the operating conditions and the activation

frequency, but should never exceed two years. These inspections are preferably carried out by qualified personnel

authorized by Hansen Industrial Transmissions nv.

In case the backstop is part of a hoist drive which is subject to a periodical safety inspection, the check of the backstop

must be included in the inspection procedure.

In case of transport of people: the user has to follow the local legislation re. the inspection of safety devices.

ENGLISH

31

FIG. 6

cooling coil

30

Loading...

Loading...