8

HARDI NAVIGATOR

Control boxes and power supply

Power requirement is 12V DC. Note Polarity!

For EVC: Brown pos. (+), Blue neg. (-).

The control boxes for EVC-operating unit and D.A.H.

are fitted in the tractor cabin at a convenient place.

Tapping screws can be used for mounting.

Connecting electric controls

Control boxes must be fitted in the tractor cabin at a

convenient place. 12 V power sockets are required.

The wires must have a cross-sectional area of at least

4.0 mm

2

to ensure sufficient power supply. The boxes

must be fused according to the following table.

Control Box Polarity / Wire colour Fuse (Amp)

(+) (-)

EC operating unit Brown Blue 8

Foam marker White Black 16

Distribution valves Brown Blue 8

NOTE! Please refer to the Boom Operator’s Manual

supplied with your sprayer documentation regarding

connecting hydraulics,boom operation, adjustment and

maintenance.

Controls Setup Procedure

Before spraying, the EVC operating unit is adjusted

using clean water (ie without chemicals).

1 Choose the correct nozzle for the spray job. Make

sure that all nozzles are the same type and capacity.

Please see your dealer or the Hardi Spray Technique

book for Nozzle selection guidance.

2 Switch on the EVC using the Controller.

3 Activate all distribution valves to the open position.

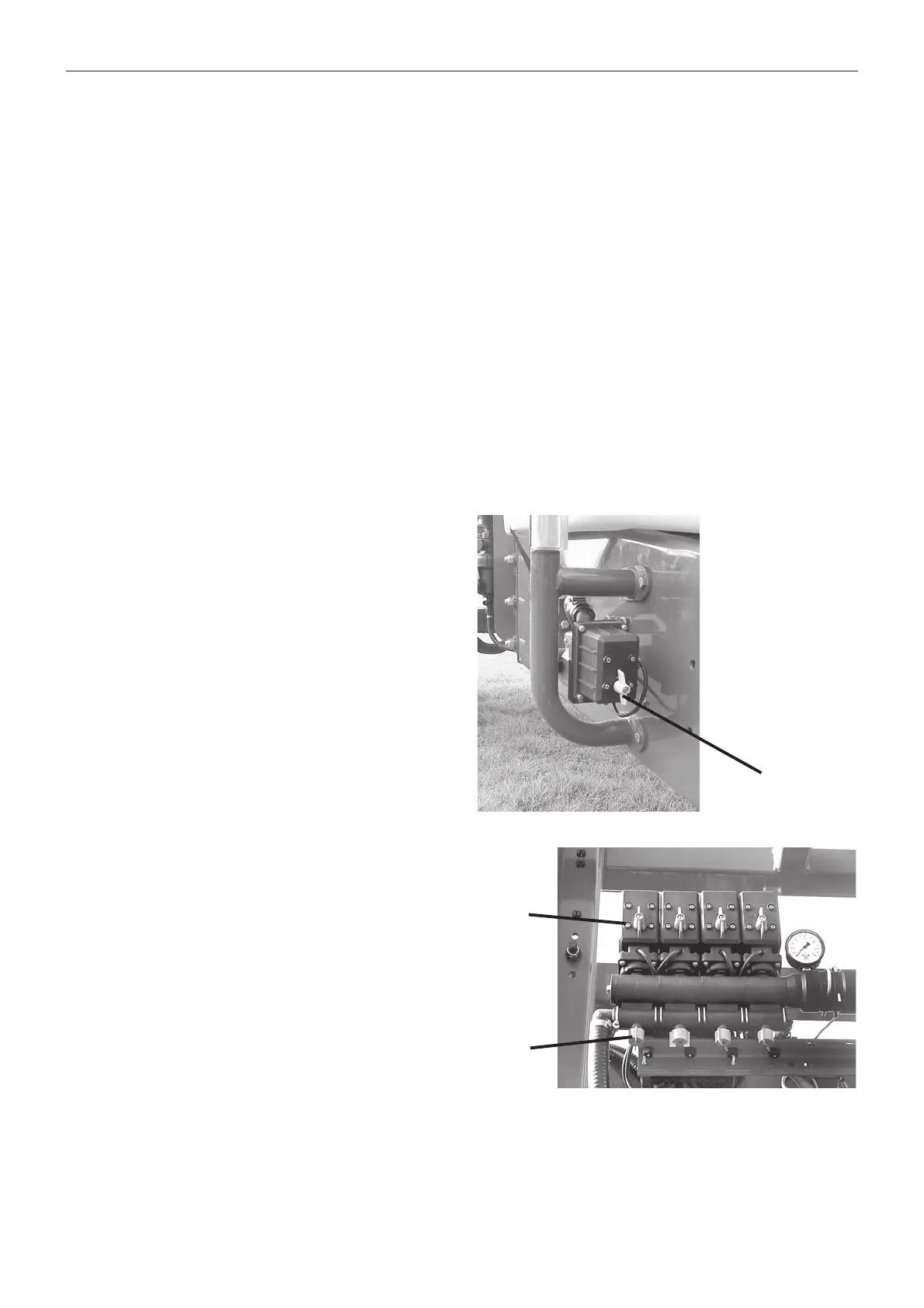

4 Decrease the pressure until the pressure control

valve handle (A Fig 9) stops rotating (min. pressure).

5 Put the tractor in neutral and adjust the PTO revolu-

tions to the intended travelling speed. ThePTO must

be kept between 300- 600 rpm (540 pump) or 650-

1100 rpm (1000 pump).

6 Increase the pressure until the required pressure is

shown on the pressure gauge.

Pressure equalisation Setup Procedure

1

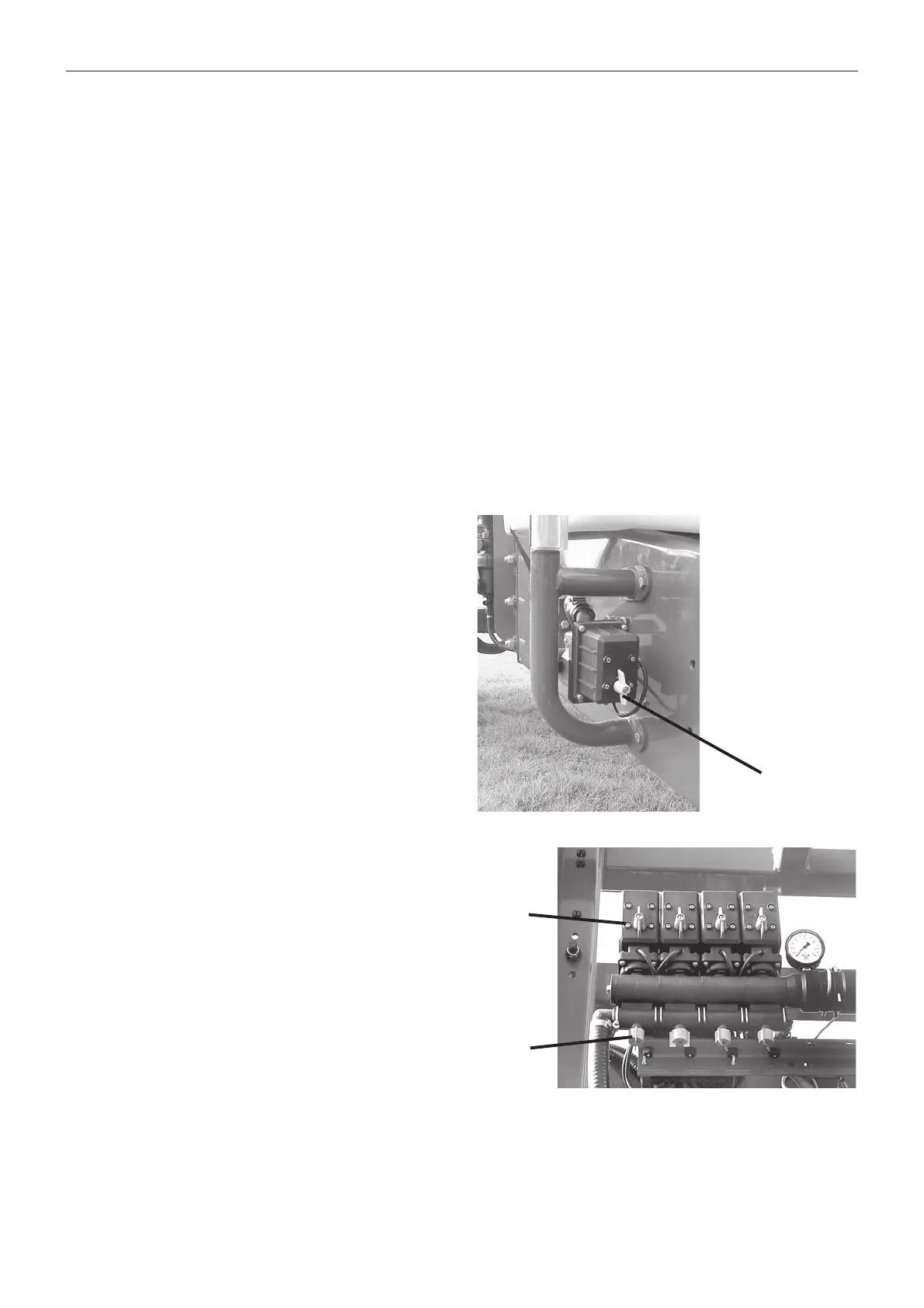

Close the first section of the distribution valves (A Fig 10).

2 Turn the first section adjusting screw (B Fig 10) until

the pressure gauge shows the same pressure again.

3 Leaving the 1st section off, repeat procedure to adjust

with the next section off. Continue until all sections are

off - the gauge should still read the same pressure.

Subsequent Adjustments

NOTE! Hereafter adjustment of pressure equalisation

will only be needed when you change to nozzles with

other capacities or the nozzleoutput increases as the

nozzles wear.

Please see your dealer or the Hardi Spray Technique

book for Nozzle selection guidance.

Emergency operation

Boom

Refer to the

Troubleshooting

section in the

FALCON or

EAGLE PARALIFT Boom Operator’s Manual

supplied

with your sprayer documentation. In case of power

failure on units fitted with solenoid valves, the boom can

be operated manually by pressing the the centre of

individual buttons on the solenoid valves. This is done

by locking the by-pass valve.

EVC Operating Unit

Refer to the

Troubleshooting

section on Page 21.

In case of power failure, the problem may be due to a

blown fuse. Refer to the Controller Manual supplied with

your sprayer.

It is possible to operate all functions of the operating unit

manually. First disconnect the Controller, then manually

turn the emergency control knobs.

Fig 10

Fig 9

A

A

B

Loading...

Loading...