31

3-90-00674R28_12/13

Maintenance - Cleaning

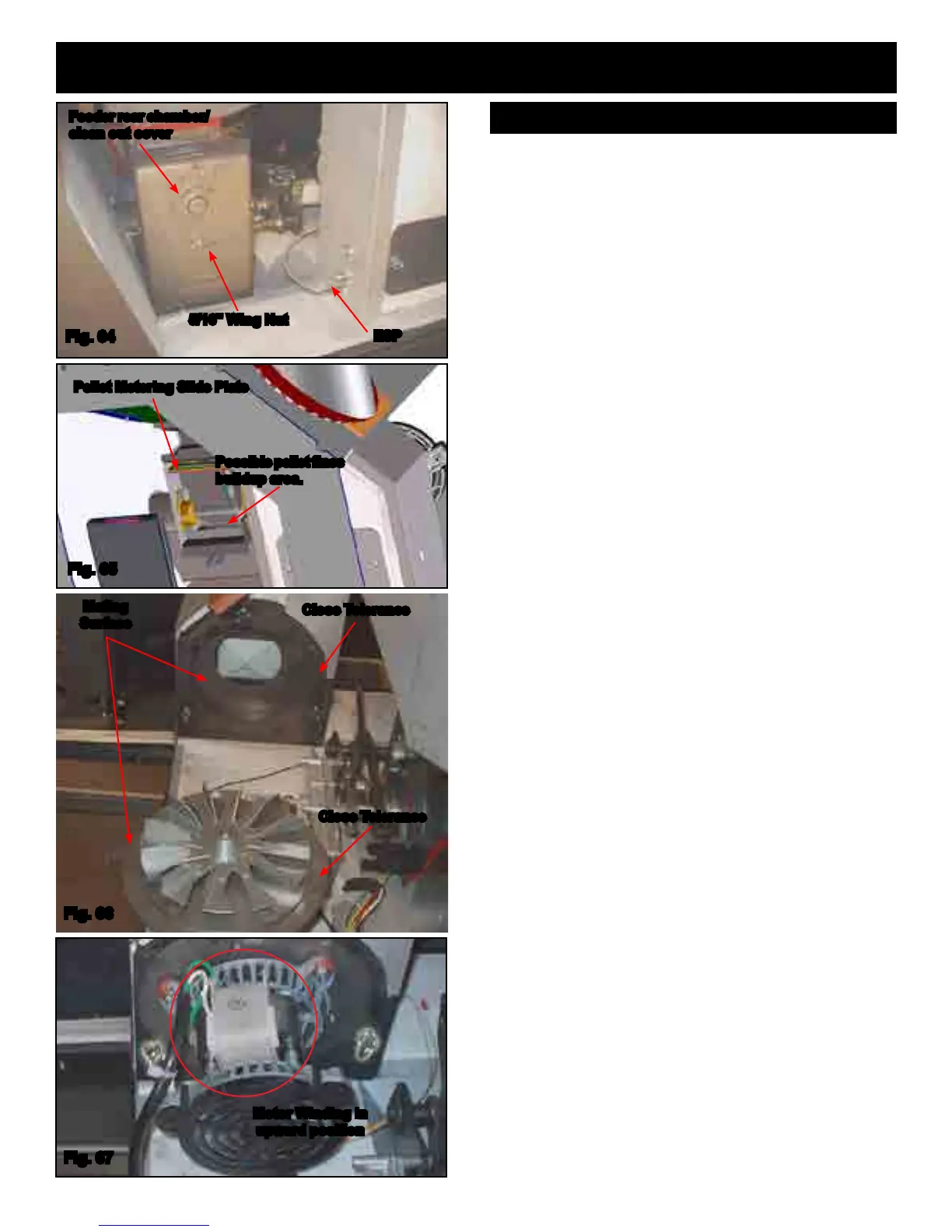

This chamber may get a buildup of nes from the feeder

mechanismmovement.This areashouldbecheckedand

cleanedatleastonceayear.

To remove the feeder cover:

• Removethe5/16"wingnut.

• Slidethecoveroffofthethreadedstud.

• Inspectandcleantheinnerchamberifnecessary.See

Fig.65.

• Reinstallthecovermakingcertainitiscenteredonthe

feederbodyandtightenastightlyasyoucanbyhand.

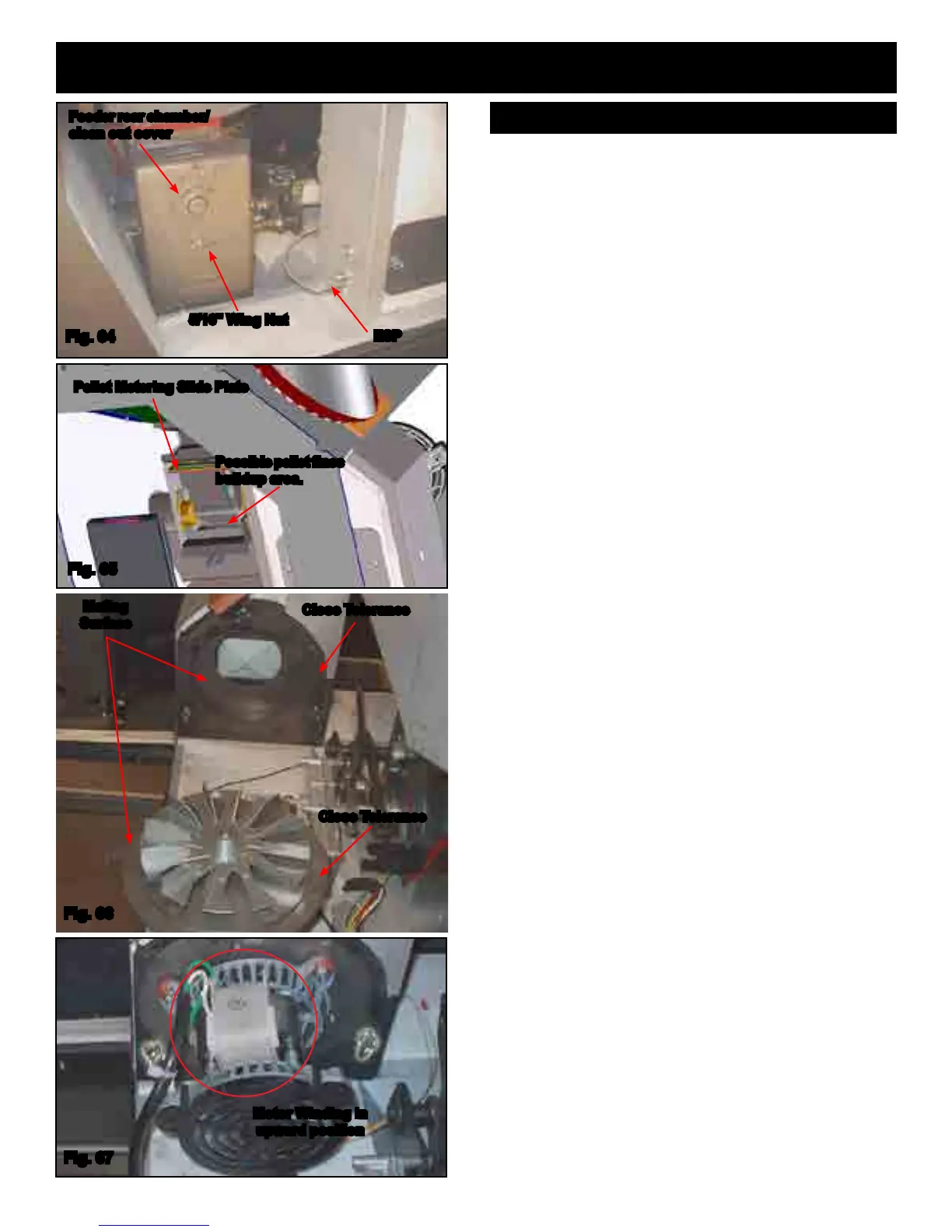

Thecombustionblowerismadetoberemovedeasilyfor

inspectionandcleaning.SeeFig.67.

The combustion blower is mounted on a precision cut

gasketlessmountingplate.Thisplateisheldintoplace

with(3)thumbscrews.SeeFig.67.

To remove the combustion blower:

• Turnthethumbscrewscounterclockwiseapproximately5

turns.Rotatetheentireassemblycounterclockwiseuntil

thepointsoftheretainingslotsarevisible.

• Removetheblowerassemblywiththefanbladebypulling

itdirectlyawayfromtheblowerhousing.

• Thecordonthemotorislongenoughtoallowthemotor

tobesetdownontheblackplasticfancover.Thisallows

foreasyaccesstoinspectandcleanthearea.SeeFig.

66.

• Withtheblowerassemblyout,inspectionshouldbedone

onthesurfacesoftheblowerassemblyandthehousing

opening where they meet. These surfaces MUST be

cleanandfreefromdirt,grit,yash,sootornicksinthe

metal.Thisgasketlesssealreliesonanextremelyclose

tolerance. Therefore, anything other than a clean joint

maycauseexhaustgasesand/oryashtoescape.

• Theassemblycanonlybereinstalledinoneposition:with

themotorwindingintheupwardlocation.SeeFig.67.The

mountingplatewillnotallowforanyotherposition.

• Alwaysmakesurethattheassemblyisfullyseatedand

the(3)thumbscrewsaretightenedbeforeoperatingthe

unit.

Feeder Chamber

Pellet Metering Slide Plate

Possible pellet nes

buildup area.

Fig. 65

5/16" Wing Nut

ESP

Feeder rear chamber/

clean out cover

Fig. 64

Mating

Surface

Close Tolerance

Fig. 66

Close Tolerance

Fig. 67

Motor Winding in

upward position

Loading...

Loading...