25

3-90-233R24_11/13

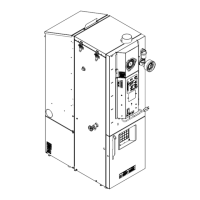

Power Light

Indicates power to the control

board. (Ready)

Status Light

Will be lit anytime the unit is

in operation.

Combustion Blower Light

Indicates Power to

combustion blower

Feed Motor Light Indicates

Power to the feed motor.

Max Temp dial

The “Max Temp Dial” is used to set the desired

maximum operating temperature of the boiler.

7 Blinks: Boilerwater overheat safety shut down (220

DegreesF.)Thisrequiresamanualresetbycyclingthemain

poweroffforafewsecondsandre-connect.

Explanation and Importance of the OverHeat Safety Zone

Whenthe unitis operatingat Highburn, andall demand

fromtheheatingsystemstops,thecontrolwillreducethe

feedrateandshutdowncompletelyasnecessary.Thismay

takeseveralminutes,andtheremainingheatmaycausethe

watertemperaturetorisetoover210degreesF.Whenthis

happens,theOVERHEATSAFETYZONElightonthecontrol

willilluminateandtherelayR1isenergized.Thiswillclose

contacts#5and #3(FanContacts on theinterconnection

Page 20), and willalso energize thecontrolled circulator

outlet,forthehotwaterdumpzone.

Whenusingahotwater coil in anairductsystem,ifyou

donotwantthelivingspaceheatedbeyondthethermostat

settingduringanoverheatdump,analternatedumpzone

willneedtobeinstalledandsomeinternalcontrolre-wiring

willbenecessary.

Feed adjuster

Sets the maximum feed rate

Test

Combustion blower, feed

motor and safety dump

zone are fully energized for

the first minute. Then, the

combustion blower will stay

on low.

Overheat Safety Zone Light

Indicates that the boiler water

temperature has reached

210 Degrees F.

Igniter Light

Indicates power to the igniter

Lighting Mode Selector

Switched between Auto and

Manual lighting.

Mode Selector/Min Temp

Dial

Used to turn the boiler on or off

and set the desired minimum

operating temperature of the

boiler.

Status light error messages:

3 Blinks:IndicatesthattheESP(ExhaustSensingProbe)

hasgoneoutofrangetoomanytimes.Iftheunitisoperating

correctly,performamanualresetbycyclingthemainpower

offatthecircuitbreakerforafewseconds.Ifthe3blinks

persist, contact your service technician.

4 Blinks:Indicatesmis-communicationwiththeaquastat,or

theaquastatisnotattachedproperly.Mayrequireamanual

reset(turnoffpoweratcircuitbreaker).Notethatinsome

optionalcontrolmethods,thisstatuswilloccurduringnormal

operationandresetautomatically.

5 Blinks:(InAutoLightModeOnly)

Indicatesthattheigniterhasfailedtolightthereafter40

Minutes.Toreset-TurntheModeSelector/Min.Temp.to

OFFandthenbacktothedesiredtemperature.

6 Blinks:Indicatesthatthecontrolhascalculatedpooror

incompletecombustionoccurringfor25ormoreminutes.

Asixblinkstatusmayoccurifthestoveisallowedtorunout

ofpellets.Toreset,turnModeSelector/MinTempdialto“OFF”

thenbackontothedesiredtemperature.Iftheunitwasnot

outofpellets,seeTroubleshootingsectionformoredetails.

Diagnostic Port

For maintenance only.

Requires special DDM

monitor supplied to trained

technicians exclusively.

Operation

Label from unit control panel showing outlets

Loading...

Loading...