23 – English

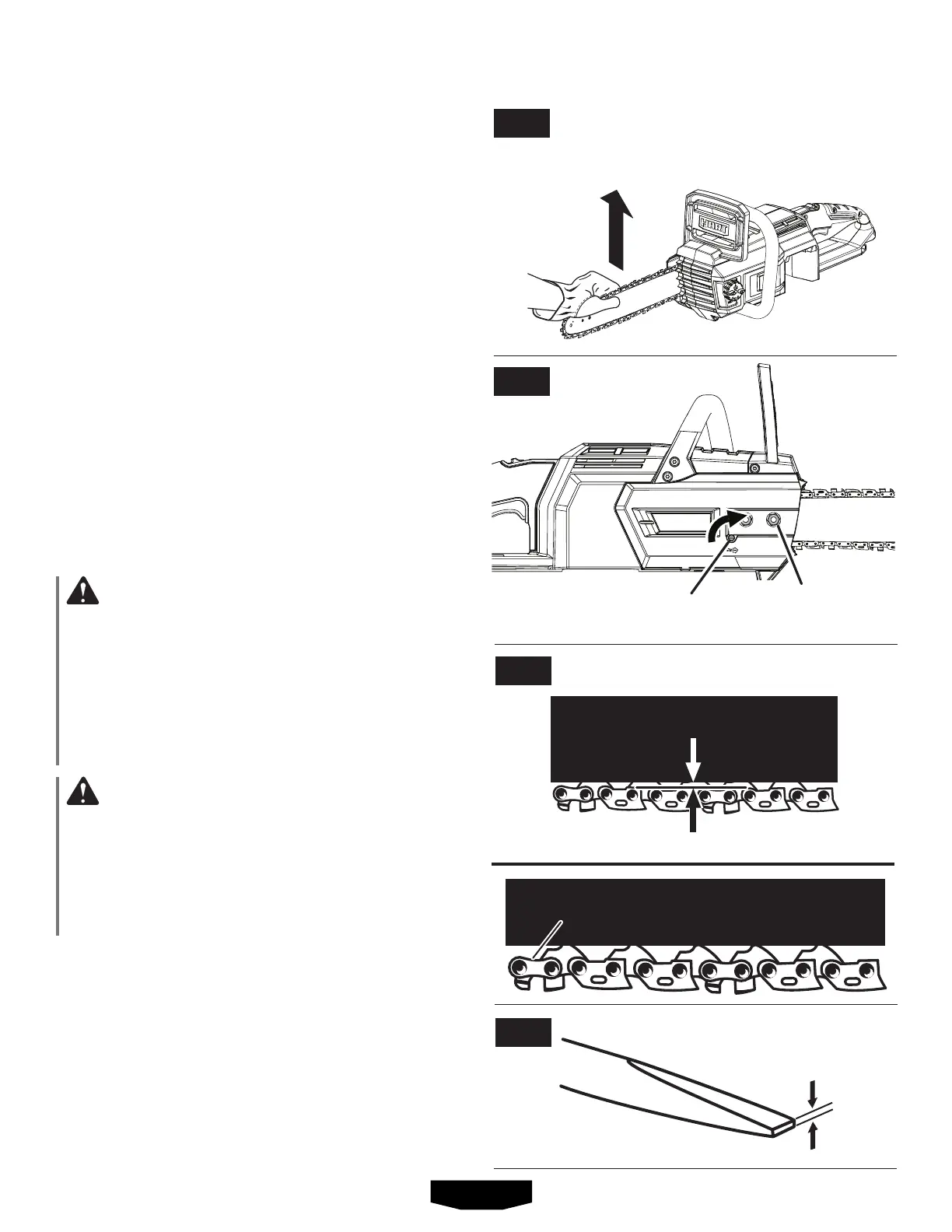

Replacethechaincoverandbarmountingnuts.

Finger-tighten the bar mounting nuts. The bar

mustbefreetomovefortensionadjustment.

Removeallslackfromthechainbyturningthe

chain tensioning screw clockwise until the chain

seatssnuglyagainstthebarwiththedrivelinks

inthebargroove.

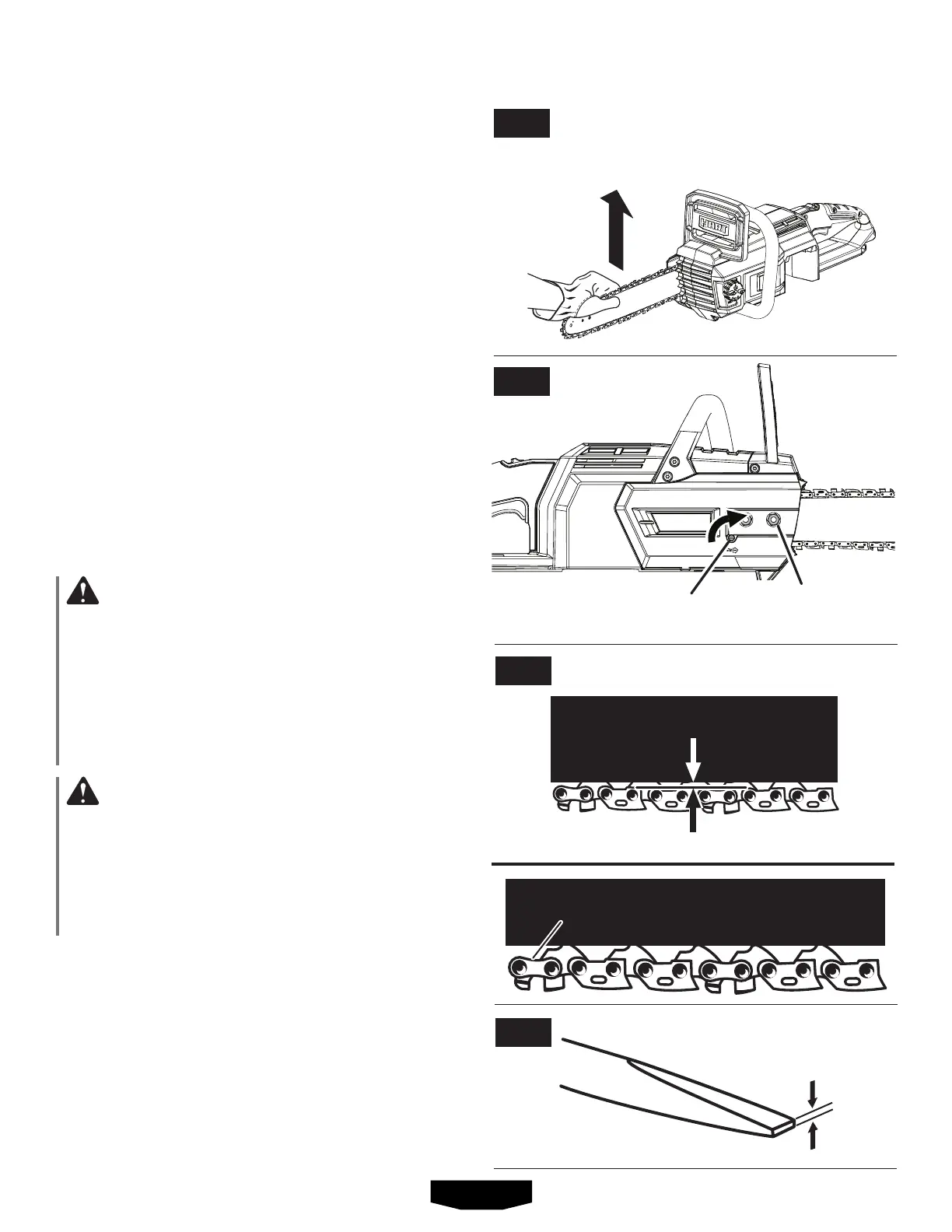

Liftthetipoftheguidebaruptocheckforsag.

Hold the tip of the guide bar up and tighten

the bar mounting nuts securely.

The chain is correctly tensioned when there is no

sag on the underside of the guide bar, the chain is

snug, but it can be turned by hand without binding.

NOTE: If chain is too tight, it will not rotate. Loos-

en the bar nuts slightly and turn the tension adjust-

er1/4turncounterclockwise.Liftthetipofthe

guidebarupandretightenthebarnutssecurely.

Ensure that the chain will rotate without binding.

ADJUSTING THE CHAIN TENSION

See Figures 30 - 32.

WARNING:

Stop the motor, wait for all moving parts to

stop,andremovethebatterypack.Nevertouch

or adjust the chain while the engine is running.

Thesawchainisverysharp.Alwayswearpro-

tectivegloveswhenperformingmaintenance

on the chain. Failure to follow these instructions

canresultinseriouspersonalinjury.

WARNING:

Stopthemotorandremovethebatterypack.

Nevertouchoradjustthechainwhilethemotor

isrunning.Thesawchainisverysharp.Always

wearprotectivegloveswhenperformingmain-

tenance on the chain. Failure to follow these in-

structionscanresultinseriouspersonalinjury.

Properchaintensioniscriticaltotheperformance

ofyourchainsaw.Alwayscheckchaintension

before usingthe saw and periodically until the

workiscomplete.

Acoldchainiscorrectlytensionedwhenthereis

no slack on the underside of the guide bar. The

chain should be snug, but still able to be turned

by hand without binding.

MAINTENANCE

CHAIN

TENSIONING

SCREW

BAR MOUNTING

NUTS

LIFT THE TIP OF THE GUIDE BAR UP TO CHECK

FOR SAG

APPROX. .050 in.

FLATS ON TIE STRAPS

≈ 0.050 in.

FIG. 29

FIG. 30

FIG. 31

FIG. 32

Loading...

Loading...