30 – English

WARNING:

Whenservicing,useonlyidenticalreplacementparts.

Useofanyotherpartscancreateahazardorcause

productdamage.

WARNING:

Alwaysweareyeprotectionwithsideshieldsmarked

to comply with ANSI Z87.1. Failure to do so could

resultinobjectsbeingthrownintoyoureyes,resulting

inpossibleseriousinjury.

WARNING:

Beforeperforminganyadjustment,makesurethetool

isunpluggedfromthepowersupply.Failuretoheed

thiswarningcouldresultinseriouspersonalinjury.

GENERAL MAINTENANCE

Avoidusing solvents whencleaningplastic parts. Most

plasticsaresusceptibletodamagefromvarioustypesof

commercialsolventsandmaybedamagedbytheiruse.Use

cleanclothstoremovedirt,dust,oil,grease,etc.

WARNING:

Donotatanytimeletbrakefluids,gasoline,petroleum-

basedproducts,penetratingoils,etc.,comeincontact

withplasticparts.Chemicalscandamage,weakenor

destroyplastic which can result in serious personal

injury.

Electrictoolsusedonfiberglassmaterial,wallboard,spack-

lingcompounds,orplasteraresubjecttoacceleratedwear

andpossibleprematurefailurebecausethefiberglasschips

andgrindingsarehighlyabrasivetobearings,brushes,com-

mutators,etc.Consequently,wedonotrecommendusing

thistoolforextended work on these typesofmaterials.

However,ifyoudoworkwithanyofthesematerials,itis

extremelyimportanttocleanthetoolusingcompressedair.

LUBRICATION

Allofthebearingsinthistoolarelubricatedwithasufficient

amountofhighgradelubricantforthelifeoftheunitunder

normaloperatingconditions.Therefore,nofurtherlubrica-

tionisrequired.

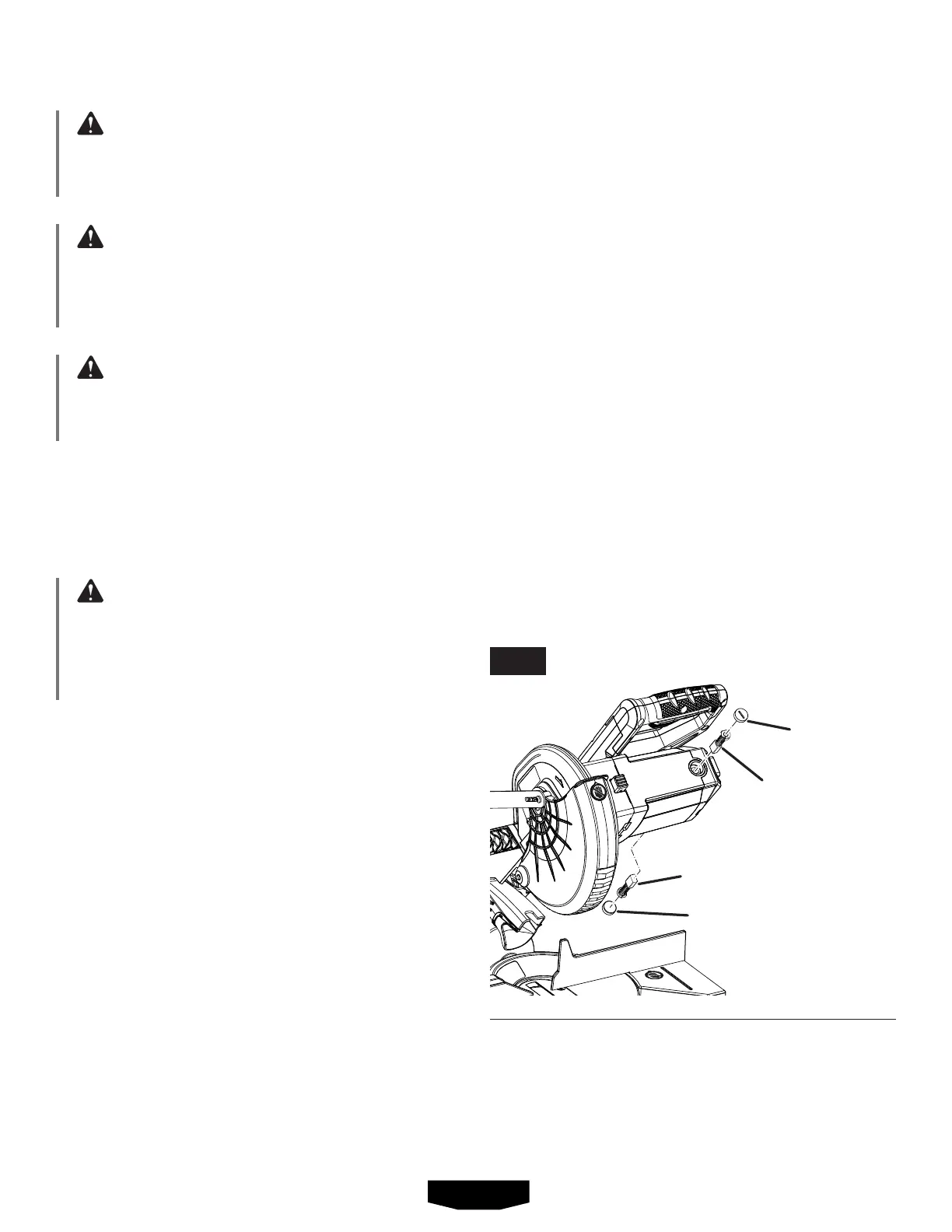

BRUSH REPLACEMENT

See Figure 35.

Thesawhasexternally accessiblebrushassembliesthat

shouldbeperiodicallycheckedforwear.

Proceed as follows when replacement is required:

Unplugthesaw.

Removebrushcapwithascrewdriver.Brushassemblyis

springloadedandwillpopoutwhenyouremovebrush

cap.

Removebrushassembly.

Checkforwear.Replacebothbrusheswheneitherhas

lessthan1/4in.lengthofcarbonremaining.Do not re-

placeonesidewithoutreplacingtheother.

Reassemble using new brushassemblies.Makesure

curvatureofbrushmatchescurvatureofmotorandthat

brushmovesfreelyinbrushtube.

Makesurebrushcapisorientedcorrectly(straight)and

replace.

Tightenbrushcapsecurely.Do notovertighten.

BRUSH

CAP

BRUSH

CAP

BRUSH

ASSEMBLY

BRUSH

ASSEMBLY

MAINTENANCE

FIG. 35

Loading...

Loading...