29 – English

WARNING:

Beforeperforminganyadjustment,makesurethetool

isunpluggedfromthepowersupply.Failuretoheed

thiswarningcouldresultinseriouspersonalinjury.

Thecompoundmitersawhasbeenadjustedatthefactory

formakingaccuratecuts.However,someofthecomponents

mighthavebeenjarredoutofalignmentduringshipping.

Also,overaperiod of time,readjustment will probably

becomenecessaryduetowear.Afterunpackingthesaw,

check thefollowingadjustmentsbefore you begin using

thesaw.Makeanyreadjustmentsthatarenecessaryand

periodicallycheckthepartsalignmenttomakesurethatthe

sawiscuttingaccurately.

PIVOT ADJUSTMENTS

NOTE:Theseadjustmentsweremadeatthefactoryand

normallydonotrequirereadjustment.

TRAVEL PIVOT ADJUSTMENT

Thesawarmshouldrisecompletelytotheupposition

byitself.

Ifthesawarmdoesnotraisebyitselforifthereisplay

inthepivotjoints, have saw repaired at yournearest

authorizedservicecenter.

BEVEL PIVOT ADJUSTMENT

Thecompoundmitersawshouldbeveleasilybyloosening

thebevellockknobandtiltingthesawarmtotheleft.

Ifmovementistightorifthereisplayinthepivot,have

sawrepairedbyatyournearestauthorizedservicecenter.

POSITIVE STOP ADJUSTMENTS

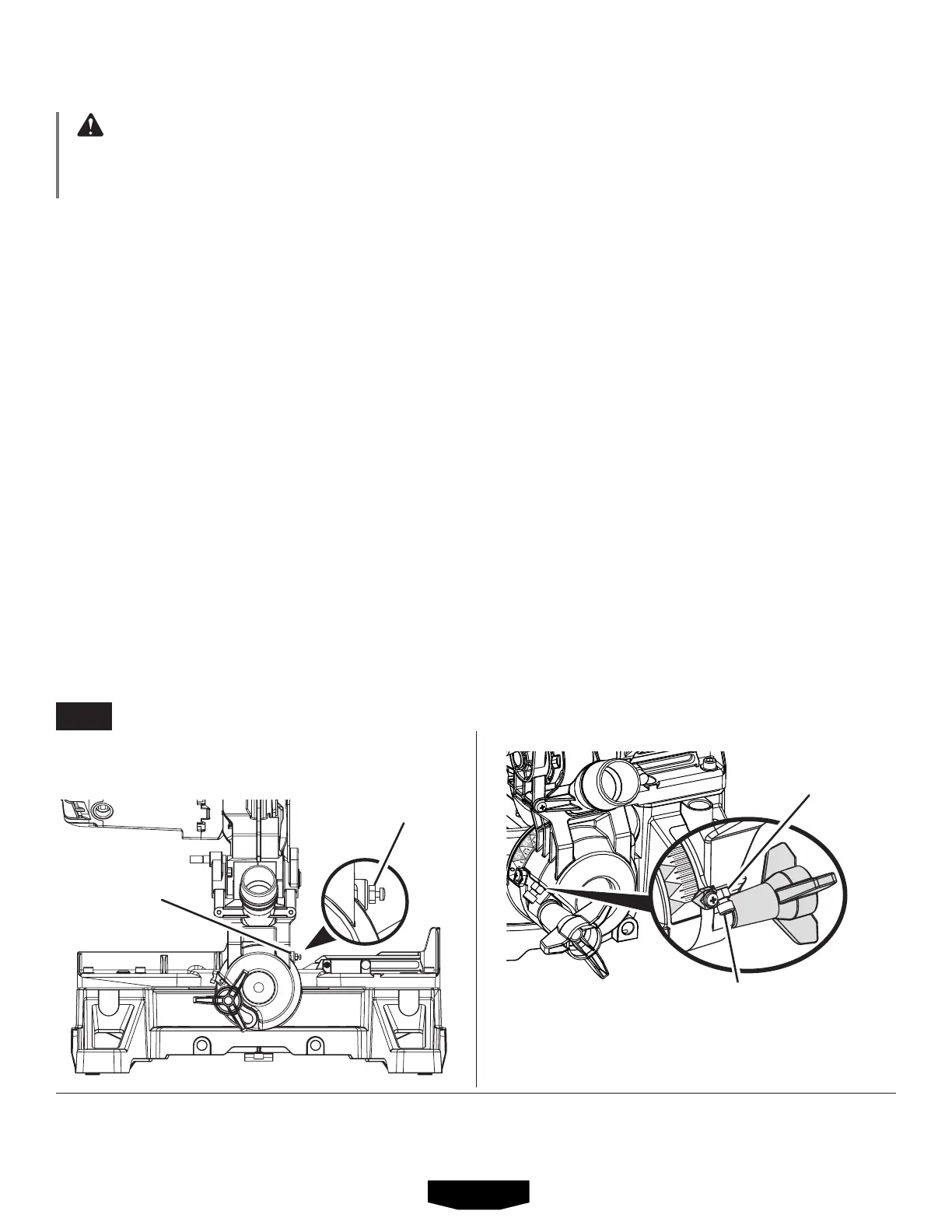

See Figure 34.

NOTE:Theseadjustmentsweremadeatthefactoryand

normallydonotrequirereadjustment.

To adjust:

Unplugthesaw.

Loosenthebevellockknobbyturningtheknobcounter-

clockwise.

Squarethebladetothemitertableasdescribedinthe

Assembly sectionofthismanual.

Ifthebladeisoutofsquare,securethelocknutinplace

andloosenortightenthepositivestopadjustmentscrew

usingthebladewrenchprovided.

Retighten bevel lock knob.Recheckblade-to-table

alignment.

NOTE: Theaboveprocedurecanbeusedtocheckblade

squarenessofthesawbladetothemitertableatboth0°

and45°angles.

Thesawhastwoscaleindicators,oneonthebevelscaleand

oneonthemiterscale.Aftersquaringadjustmentshavebeen

made,itmaybenecessarytoloosentheindicatorscrews

andresetthemtozero.See figures 20 - 21.

LOCK NUT

POSITIVE STOP

ADJUSTMENT

SCREW FOR

0

°

ANGLES

LOCK NUT

POSITIVE STOP

ADJUSTMENT

SCREW FOR

45

°

ANGLES

ADJUSTMENTS

FIG. 34

Loading...

Loading...