ADJUSTING HA-104 HOLD DOWN FOOT _

1. Release blade tension by flipping earn-over handle up.

2. Loosen knob at the top of hold down arm.

3. Rotate foot counter-clockwise to blade. Slide blade through

cutout at end of foot and center in foot.

4. Adjust to desired height.

5. Tighten threaded knob.

6. Tension blade.

TENSIONING THE DRIVE BELT _

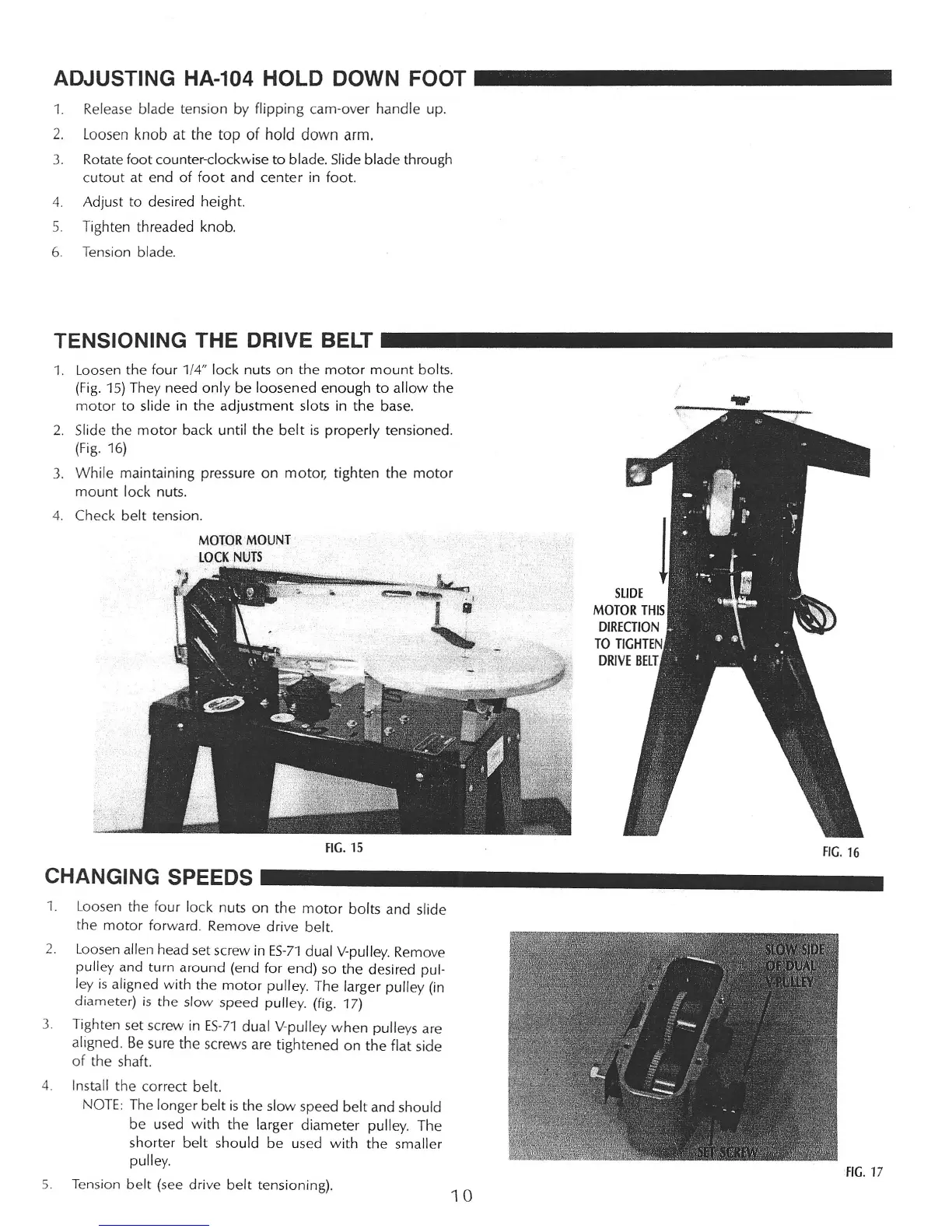

1. Loosen the four

1/4"

lock nuts on the motor mount bolts.

(Fig. 15) They need only be loosened enough to allow the

motor to slide in the adjustment slots in the base.

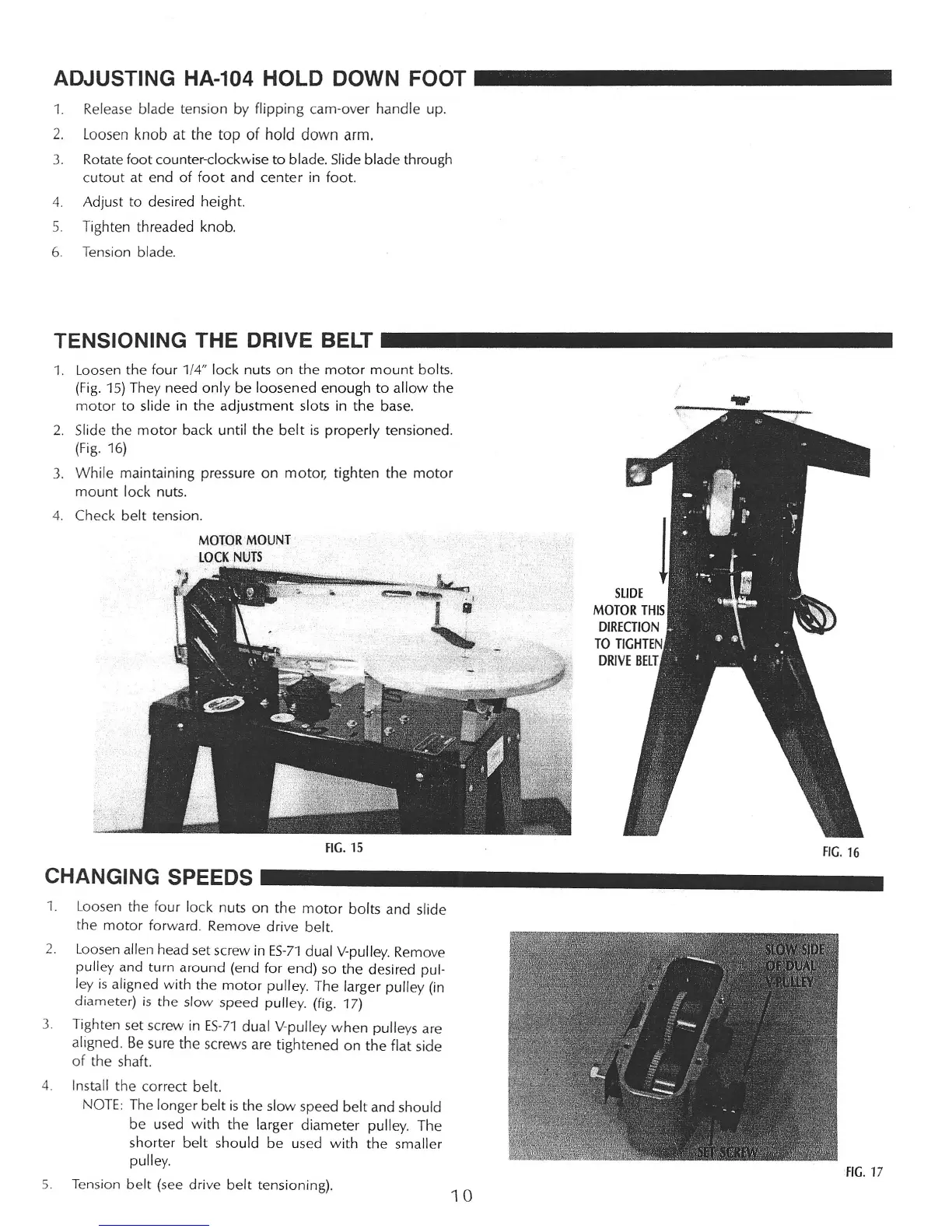

2. Slide the motor back until the belt is properly tensioned.

(Fig. 16)

3. While maintaining pressure on motor, tighten the motor

mount lock nuts.

4.

Check belt tension.

FIG. 15

'

....

SLIDE

MOTOR THIS

DIRECTION

TO TIGHTEN

DRIVE BELT

CHANGING SPEEDS _

FIG. 16

1. Loosen the four lock nuts on the motor bolts and slide

the motor forward. Remove drive belt.

2.

Loosen allen head set screw in ES-71dual V-pulley. Remove

pulley and turn around (end for end) so the desired pul-

ley is aligned with the motor pulley. The larger pulley (in

diameter) is the slow speed pulley. (fig.

17)

Tighten set screw in ES-71dual V-pulley when pulleys are

aligned. Be sure the screws are tightened on the flat side

of the shaft.

Install the correct belt.

NOTE: The longer belt is the slow speed belt and should

be used with the larger diameter pulley. The

shorter belt should be used with the smaller

pulley.

Tension belt (see drive belt tensioning).

3.

4.

5.

10

FIG. 17

Loading...

Loading...