15

Installation, Operation & Maintenance AIR HANDLER SERIES Heat Controller, Inc.

ECM Blower Control

The ECM fan is controlled directly by the DXM2/AXM control

board that converts thermostat inputs and CFM settings to signals

used by the ECM motor controller. To take full advantage of the

ECM motor features, a communicating multi-stage thermostat

should be used.

The AXM control maintains a selectable operating airfl ow [CFM]

for each heat pump operating mode. For each operating mode

there are maximum and minimum airfl ow limits. See the ECM

Blower Performance tables for the maximum, minimum, and

default operating airfl ows.

Airfl ow levels are selected using the confi guration menus of a

communicating thermostat or diagnostic tool. The confi guration

menus allow the installer to independently select and adjust the

operating airfl ow for each of the operating modes. Air fl ow can be

selected in 25 CFM increments within the minimum and maximum

limits shown in Table 8. The blower operating modes include:

• First Stage Cooling (Y1 & O)

• Second Stage Cooling (Y1, Y2, & O)

• First Stage Cooling in Dehumidifi cation Mode

(Y1, O, & Dehumid)

• Second Stage Cooling in Dehumidifi cation Mode

(Y1, Y2, O, & Dehumid)

• First Stage Heating (Y1)

• Second Stage Heating (Y1 & Y2)

• Third Stage (Auxiliary) Heating (Y1, Y2, & W)

• Emergency Heating (W with no Y1 or Y2)

• Fan (G with no Y1, Y2, or W)

The ECM motor includes “soft start” and “ramp down” features.

The soft start feature is a gentle increase of motor rpm at blower

start up. This creates a much quieter blower start cycle.

The ramp down feature allows the blower to slowly decrease rpm

to a full stop at the end of each blower cycle. This creates a much

quieter end to each blower cycle and adds overall unit effi ciency.

The ramp down feature is eliminated during an ESD (Emergency

Shut Down) situation. When the DXM2 ESD input is activated,

the blower and all other control outputs are immediately de-

activated.

The duration of the “ramp down” periods are adjustable from

0 seconds to 255 seconds. This adjustment is available in the

Aifl ow Selection screen using the communicating thermostat or

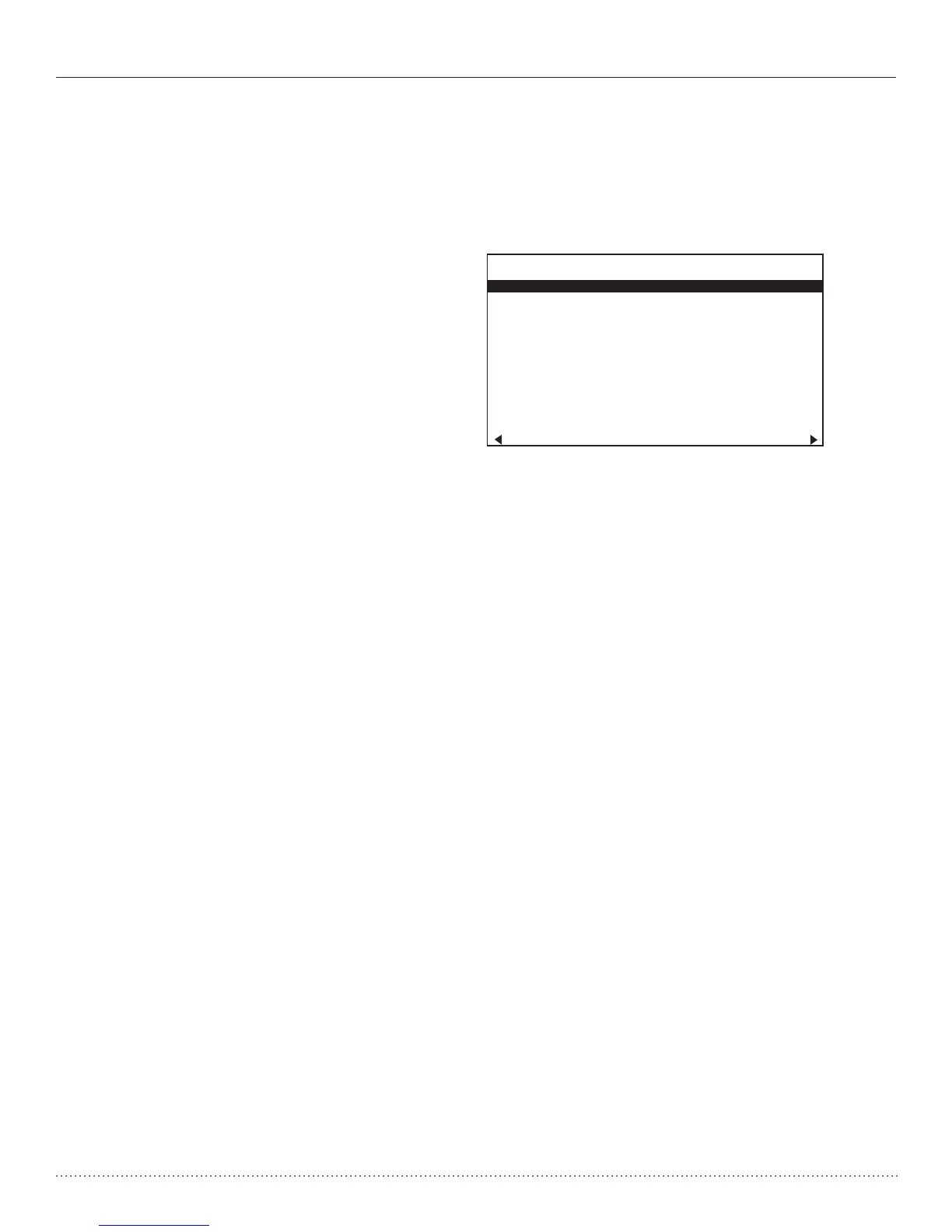

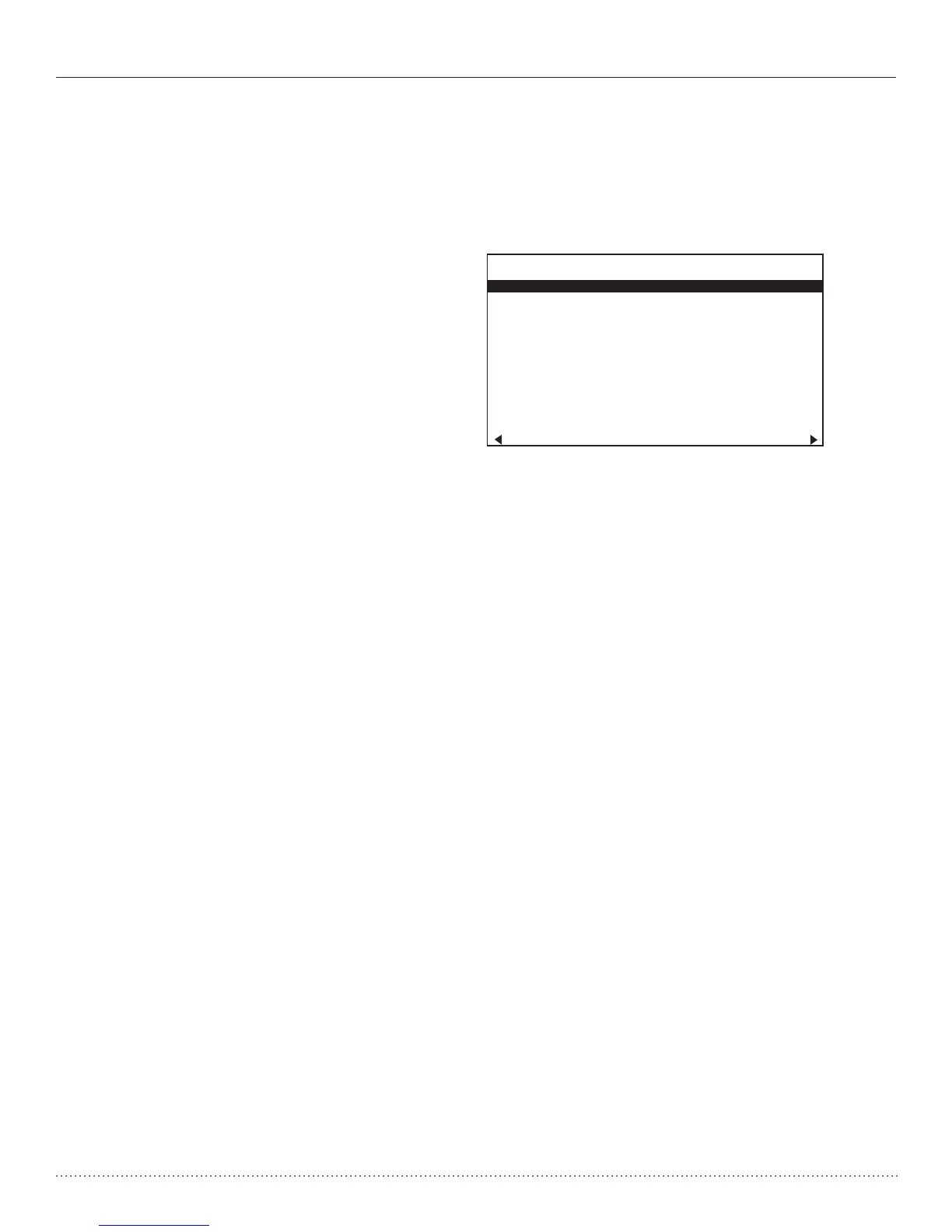

confi guration/diagnostics tool, see Figure 8.

Special Note for AHRI Testing: To achieve rated airfl ow for AHRI

testing purposes, it is necessary to change the CFM settings to

rated airfl ow.

AIRFLOW SELECTION

CFM

HEAT STAGE 1 600

HEAT STAGE 2 750

AUXILIARY HEAT 850

EMERGENCY HEAT 850

COOL STAGE 1 525

COOL STAGE 2 700

COOL DEHUMID 1 425

COOL DEHUMID 2 550

CONTINUOUS FAN 350

HEAT OFF DELAY 60

COOL OFF DELAY 30

PREVIOUS NEXT

Figure 8: Airfl ow Confi guration Screen on Communicating

Thermostat

Loading...

Loading...