INSTALLATION INSTRUCTIONS Fan Coil: FMA4X, FMA4P

Specifications subject to change without notice.

6

496 01 8001 04

!

WARNING

ELECTRICAL OPERATION HAZARD

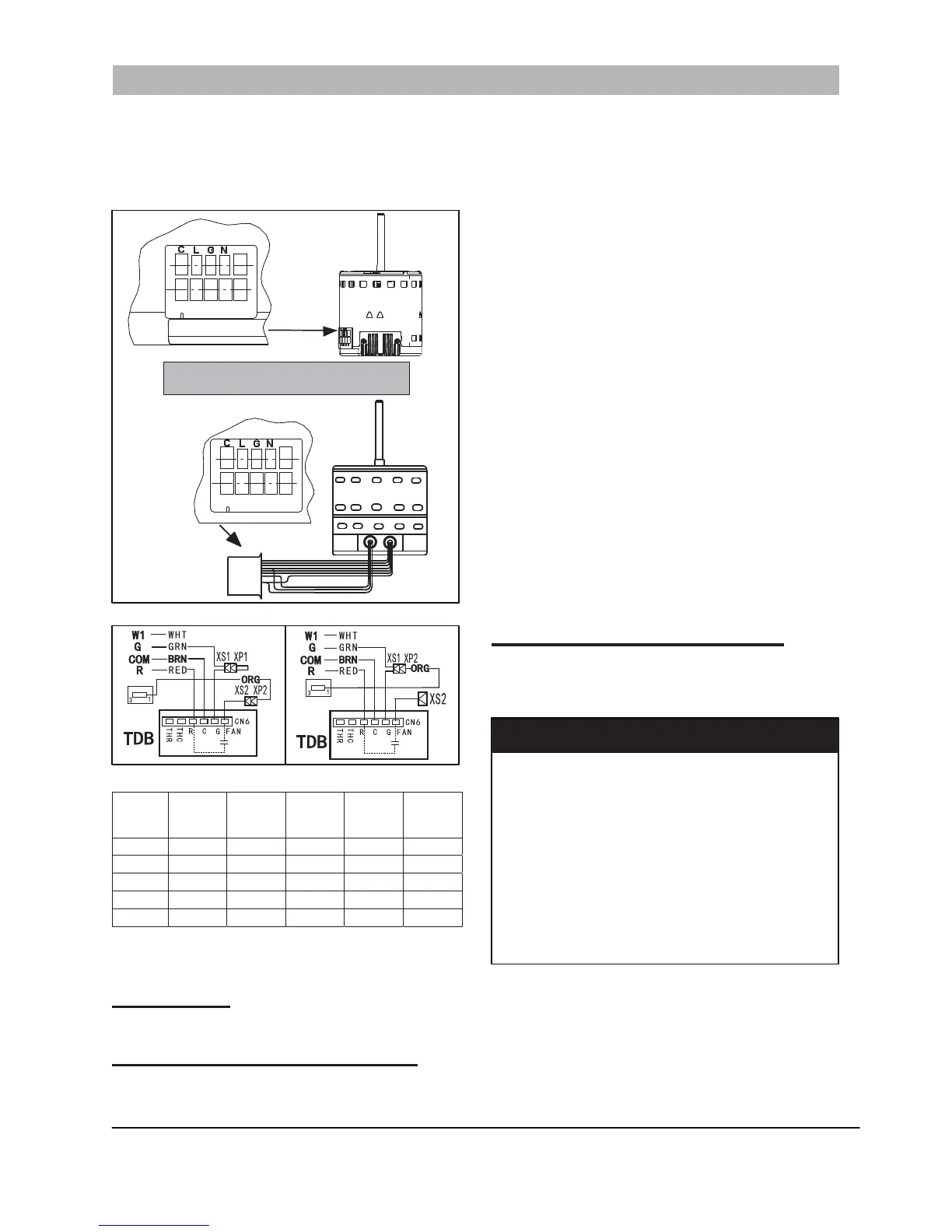

To change the fan speed on model FMA4X:

At the motor connection plug connect the green wire to the

desired motor tap number indicated on the motor plug. (See

Figure 9

) For the electric heat fan speed selection connect

the white wire to the desired motor tap number indicated on

the motor plug. See

Table 2

for factory default settings.

Figure 9

-

FMA4X ECM Motor Speed Taps

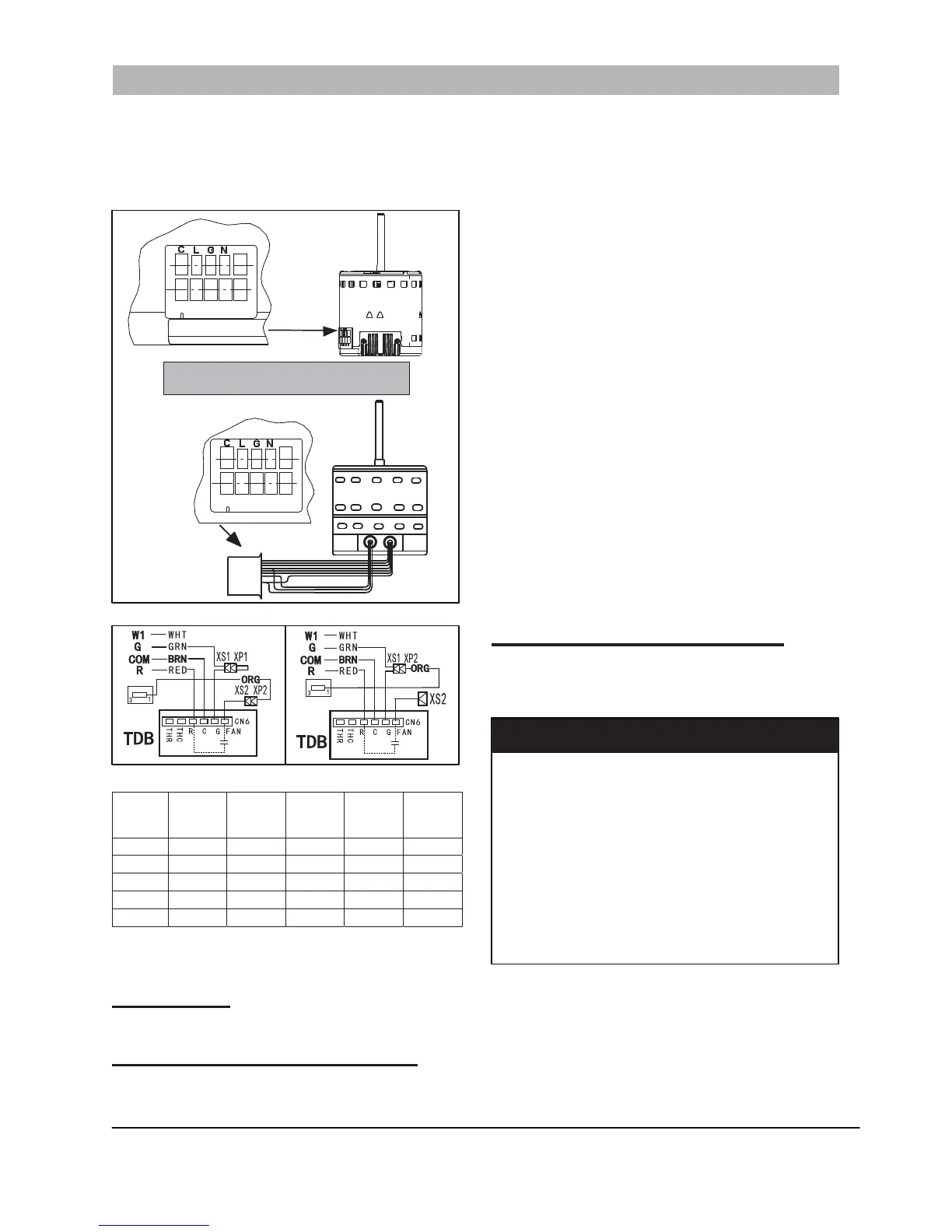

Figure 10 - Wiring Layout FMA4P PSC Motor disable time delay

A.

CONTINUOUS FAN

Thermostat closes R to G. G energizes and completes circuit

to indoor blower motor. When G is de

-

-

-

energized, there is a

90’s blower off

-

delay.

B.

COOLING MODE

Thermostat energizes R to G, R to Y, and R to O (heat pump

only). G energizes and completes indoor blower motor. Y

energizes outdoor unit (O is energized for heat pump). When

cooling call is satisfied, G is de

-

energized, there is a 90s

blower off

-

delay.

C.

HEAT PUMP HEATING MODE

Thermostat energizes R to G and R to Y. G energizes and

completes circuit to indoor blower motor. When heating call is

sa

tisfied, G is de

-

energized, there is a 90s blower off

-

delay.

D.

HEAT PUMP HEATING WITH AUXILIARY ELECTRIC

HEAT

Thermostat energizes R to G, R to Y, and R to W1. G

energizes and completes circuit to indoor blower motor. W1

energizes electric heat relay(s) which completes circuit to

heater element(s). When W1 is de

-

energ

ized, electric heat

relay(s) open, turning off heater elements. When G is

de

-

energized there is a 90s blower off

-

d

elay.

E.

ELECTRIC HEAT OR EMERGENCY HEAT MODE

Thermostat energizes R to W1. W1 energizes electric heat

relay(s) which completes circuit to heater elements(s). Blower

motor is energized through normally closed contacts on fan

relay. When W1 is de

-

energized, electric heat relay(s) opens,

there is no blower off

-

delay, (units with ECM motor will have

blower off

-

delay based on motor speed tap selection).

CARE AND MAINTENANCE

For continuing high performance and to minimize possible

equipment failure, it is essential that periodic maintenance be

performed on this equipment. The only required maintenance

that may be performed by the consumer is filter maintenance.

Table 2 – FMA4X ECM Motor Speed Taps

A11048

Tap

18 24 30 36

Tap 1

30

--- --- --- ---

Tap 2

90

--- ---

Tap 3

30

--- --- --- ---

Tap 4

90

--- ---

Tap 5

30

--- --- --- ---

Step 7 — TXV (FMA4X Only)

NOTE

: The TXVs are preset at the factory and do not need

adjustment for reliable operation.

START

-

UP

Refer to outdoor unit Installation Instructions for system

start

-

up instructions and refrigerant charging method details.

SEQUENCE OF OPERATION

NOTE

: The following sequence of operation is based on

units installed with PSC motor and Time Delay Board (TDB).

For units with ECM motor, the off

-

delay is programmed into

The minimum maintenance requirements for this equipment

are as follows:

1.

Inspect and clean or replace air filter each month or as

required.

2.

Inspect cooling coil, drain pan, and condensate drain

each cooling season for cleanliness. Clean as

necessary.

3.

Inspect blower motor and wheel for cleanliness each

heating and cooling season. Clean as necessary.

1 2 3 4 5

C L G N

1 2 3 4 5

Delay-

off

Time(s)

Default Default

Default Default

Failure to follow this warning could result in personal

injury or death.

Disconnect all power to unit before servicing field wires or

removing control package. The disconnect (when used)

on access panel does not allow safe service to all other

parts of unit.

If unit does not have a disconnect, disregard the foregoing.

Instead, make sure that a disconnecting means is within

sight from, and is readily accessible from, the unit.

Disconnect all electrical power to unit before performing

any maintenance or service on it. Lock out and tag switch

with a suitable warning label.

the motor. Follow Table 2, ECM Motor Speed Taps & the

corresponding blower off delays for each speed tap. PSC

models are factory wired with TDB active. Follow Figure 10 to

disable blower off time delay. When wired in this configuration

no blower off-delay will occur in any mode.

FR

FR

Speed Taps may be located on motor, or on

plug close to motor.

Loading...

Loading...