INSTALLATION INSTRUCTIONS Fan Coil: FMA4X, FMA4P

Specifications subject to change without notice.

2

496 01 8001 04

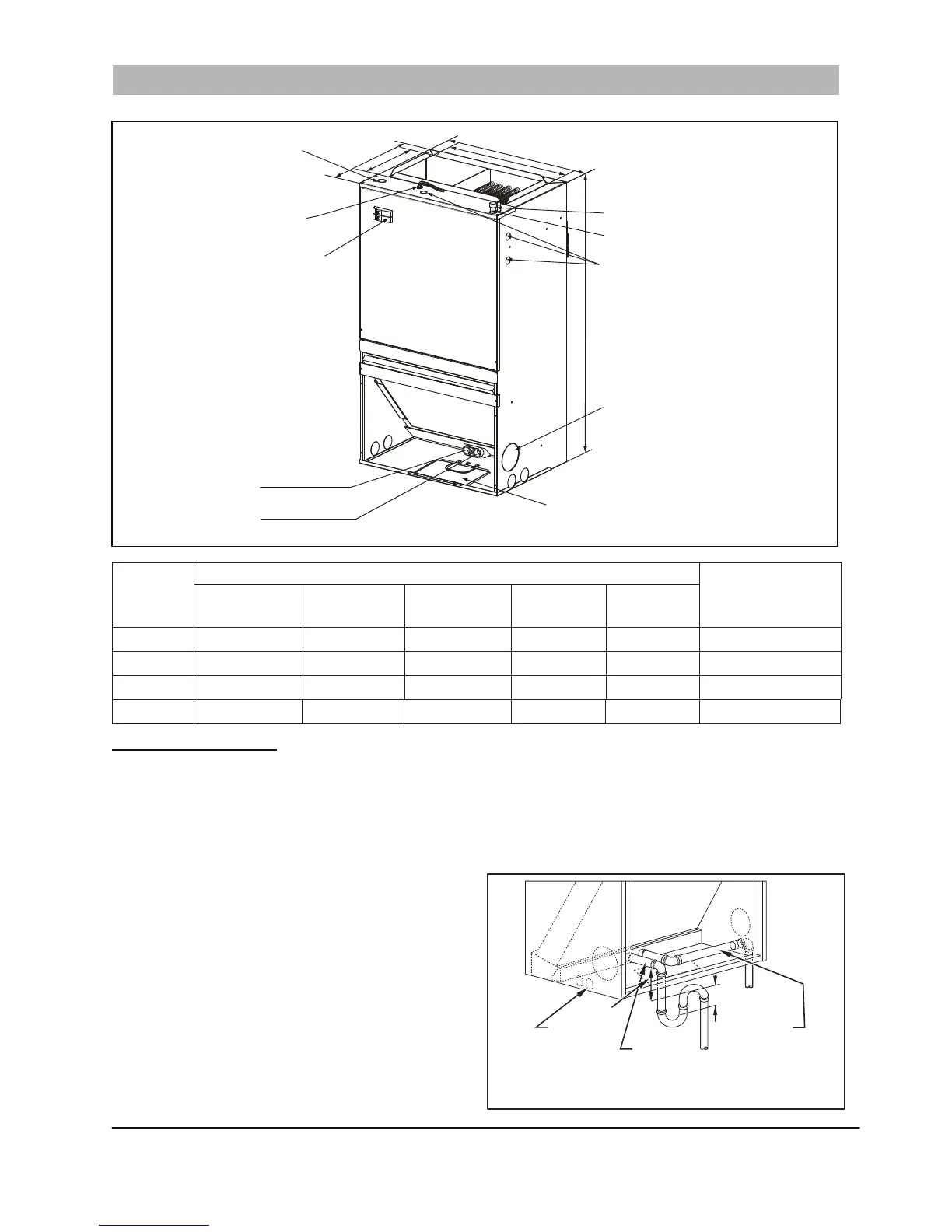

Figure 1 - Dimensional Drawing with Circuit Breaker

Table 1 – Dimensional Data

A170625

Model Size

Dimensions- In. (mm)

Unit Weight /

Shipping Weight

Lbs. (kg)

Unit Height

H

Unit Width

W

Unit Width

W1

Unit Depth

D

Unit Depth

D1

PSC 18K/24K 36-1/2 (928) 20-1/2 (521) 17-2/5 (442) 15 (381) 9-1/2 (242) 86 / 101 ( 39 / 46 )

PSC 30K/36K 39-1/2 (1004) 22 (559) 18-4/5 (478) 19 (483) 9-1/2 (242) 101 / 123 ( 46 / 56 )

ECM 18K/24K

36-1/2 (928) 20-1/2 (521) 17-2/5 (442) 15 (381) 9-1/2 (242) 79/ 95 ( 36 / 43 )

ECM 30K/36K 39-1/2 (1004) 22 (559) 18-4/5 (478) 19 (483) 9-1/2 (242) 97/ 119 (44 / 54 )

INSTALLATION

Step 1 — Check Equipment

Unpack unit and move to final location. Remove carton,

taking care not to damage unit. Remove protective sheet

metal from the base of the unit, if equipped. Inspect

equipment for damage prior to installation. File claim with

shipping company if shipment is damaged or incomplete.

Locate rating plate on unit. It contains information needed to

properly install unit. Check rating plate to be sure unit

matches job specifications. A front access panel is provided,

which permits ac

ce

ss to blower assembly and electrical

controls for removal and servicing.

NOTE

: Minimum clearance of 21” (533 mm) is required in

front of access panel for servicing only. Installation clearance

from combustible materials is 0” (0 mm) from cabinet and

supply

-

air duct (plenum included). Ensure there is adequate

space on top of unit for refrigerant line connections and on

bottom of unit for condensate trap. (See

Figure 1

and

Figure 2

.)

Step 2 — Mount Fan Coil

Fan Coil Mounting Options

The fan coil comes standard with two different options for

mounting: wall mount or frame mount. Both mounting options

require the unit to be level from side to side and from front to

back in order to allow condensate to properly drain from the

unit. Failure to do this will result in condensate leaking out

from the unit, potentially causing structural damage to the

surrounding support structures, drywall, carpet, etc. around

the unit. Also, both mou

nting structures require the ability to

accommodate a minimum of load of 150 pounds. Failure to

do this will cause damage to the support structure and

potentially damage the unit.

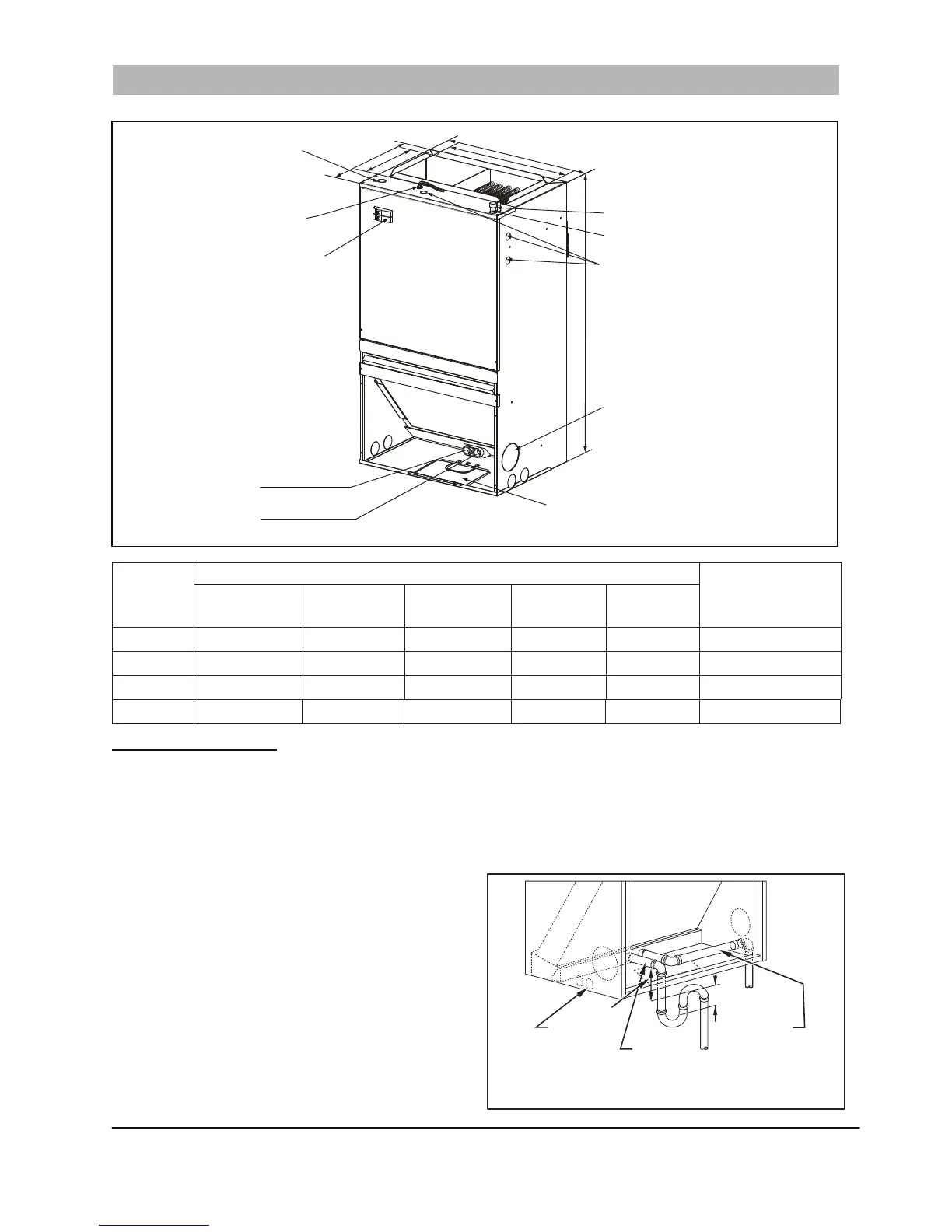

Figure 2 - Condensate Drain

A13011

PRIMARY

DRAIN

2" / 51mm

MIN DRAIN

ALTERNATE

DRAIN EXITS ON

SECONDARY

DRAIN

(TRAP EXTERNAL

TO UNIT)

NOTE: Use plastic pipe from

condensate pan to

exterior of fan coil.

2" / 51mm

MIN

EITHER SIDE OF UNIT

All units are vertical upflow only.

Equipment shown with field-installed electric heat.

Low voltage

connection

Breaker switch

(comes with

accessory

electric heater only)

D1

D

W1

W

H

Return air opening

High voltage connection

7/8” (22 mm) dia

knock outs

(both sides of unit)

Some heater sizes may

require a conduit larger than

the 7/8” (22 mm) opening;

in this situation the high-voltage

connection opening should be

enlarged to fit conduit.

Vapor line comection

copper (sweat)

Liquid line comection

copper (sweat)

Auxiliary drain connection

3/4” (19 mm) female

pipe thread (fpt)

Primary drain connection

3/4” (19 mm) female

pipe thread (fpt)

Front return shown. Units

may also be installed as

bottom return. See the

applications section for

more detail.

NOTE:Hand tighten only

High voltage connection

1-1/8” (28 mm) dia

knock outs

Fresh air intakes,

4” (101.6mm) dia

knock outs

Remove the screws and

the access plate for drain

lines service.

Loading...

Loading...