MAINTENANCE | PAGE 20

Lamp specifications:

• Name: single ended halide

• Base Designation: MOG(E39)

• Bulb Designation: BT37

• Lamp Wattage (W): 1000W

• Operating Voltage (V): 263V

• Operating Current (Amps): 4.1A

10. Hydraulic-oil unit.

• Check the hydraulic-oil unit and hydraulic oil level every 300 hours

or 3 months of work. Fill up with the same oil if necessary, always

eliminating any oil leakage that may exist.

• If the hydraulic cylinder rises unevenly or intermittently, check the

hydraulic oil level.

• Change of hydraulic oil every 2400 hours or 2 years of work or

when it loses its properties or in the case that it is contaminated by

another product.

• Each time the hydraulic oil change is performed, the lter is changed

and the tank cleaned.

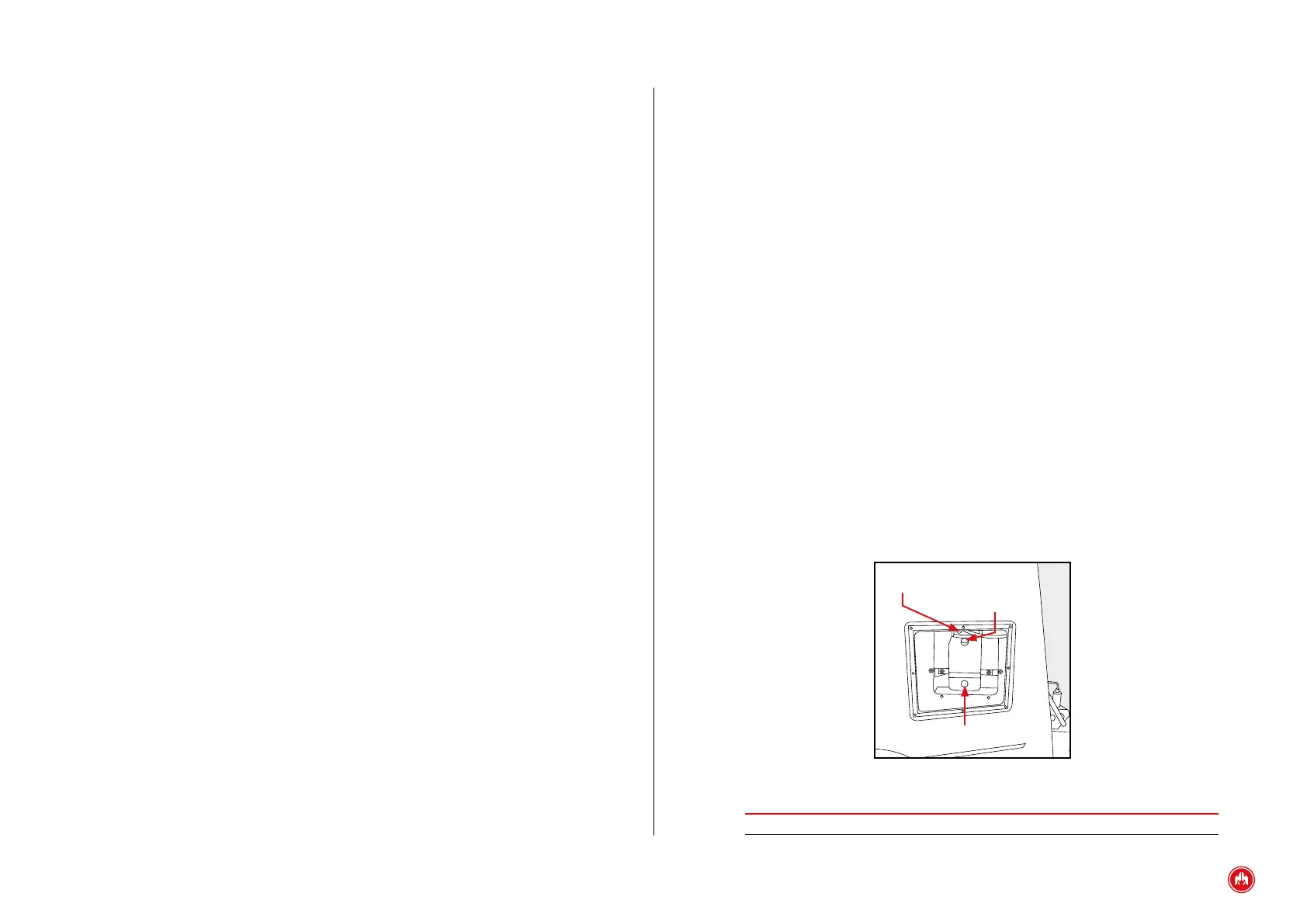

• In the event that the electrovalve does not work or another problem

prevents the mast from descending automatically, this operation is

carried out by loosening the electrovalve screw. To lower the mast it is

important that the electro-valve screw is well tightened.

• Perform a revision of the hydraulic-oil unit if hydraulic oil is detected

on the ground.

Fig. 1

8. Steel cables and pulley sets:

• Carry out periodic checks of the cables state, every 100hours or

once a month.

• When the steel cable decreases by 10% of the rated diameter due to

corrosion or abrasion, it must be replaced immediately.

• Check the cables. If a steel cable has broken, replace it as soon as

possible.

• If there is any manner of deformation (a loop, a knot or crushing),

replace the cable immediately.

• Important: always use the Steel cables indicated by the manufacturer

of the lighting tower (type 6x37 +1).

• Lubricate galvanized cables with oil when operating in high corrosion

conditions every 300hours or 3months.

9. Replacing the light bulbs and glasses.

The metal halide bulbs used in the column lights provide more powerful lighting

than ordinary halogen bulbs, for a lower consumption, with a very high service life

of approximately 8,000 hours.

Metal halide bulbs are discharge bulbs that operate using the emission of

electromagnetic rays by an ionized gas plasma. The gas is ionized using an

electric discharge (hence the name) through the gas itself.

Metal halide lamps are derived from high pressure sodium vapour lamps, with

additives (thallium, indium, dysprosium, holmium, caesium, thulium) which

improve the colour rendering of sodium lamps, giving them a very high colour

temperature (4,000-5,600 K). Their chromatic performance makes them

particularly useful when perfectly white light is required. They require special

igniters and injectors to light and these produce pulses of start-up voltage of

between 0.75 and 5 kV. During the lighting phase, it takes several minutes to

reach the maximum light output.

To replace the light bulb or glass, follow the procedure below:

• Unx the screw of the clamp (M5) with a star-shaped screwdriver and

place the clamp and the glass on a safe place.

• Replace the bulb or glass.

• Place the glass on the clamp and then both of these in the body of

the lamp. Check that the clamp has been set in place properly and

tighten the screw.

NOTE

If in doubt, contact our technical service.

Electro-valve screw

Oil ller cap

Oil drain cap

Loading...

Loading...