SERVICE & ROUTINE MAINTENANCE

CAUTION: maintenance and repairs must be carried out

by authorized personnel only. To prevent injury, always

remove the power cable from the power supply before

undertaking any work on the machine. Do not operate this

machine unless it is fully assembled and all guards are in

place. Use Hiretech genuine spare parts only.

General

1. Always make a list when first examining the machine, to

remind you of parts or action needed on completion of routine

maintenance.

2. The HTF-2 Floor Sander is subject to high speeds and

vibration, all screws should be fitted using a suitable thread

lock compound.

3. The HTF-2 Floor Sander needs no lubrication during routine

servicing.

4. Always ensure that the electrical supply is disconnected

before starting any routine servicing or repair.

5. Follow a regular schedule of routine maintenance to keep

your HTF-2 Floor Sander in good working.

Visual Inspection

1. To clean the machine and remove dust, use a vacuum cleaner

to avoid damage and prevent inhalation of dust.

2. Examine all external parts of the floor sander making sure

there is no damage. Check the condition of the Dust Brush

and Bumper around the base of the floor sander, both of

which should be undamaged and in good condition. Check

that the Handle Yoke unlocks and moves freely in its operating

position.

3. Examine the sanding pads. These should be undamaged and

in good condition. They should fit firmly to the fixing posts and

pivot slightly forward and back.

4. Examine the power cable for damage. If the outer insulation

shows the slightest of abrasions or the inner conductors are

exposed then the cable must be replaced. The cable must not

be repaired with tape or insulation sleeve.

5. Ensure all labels are sound, readable and secure.

6. Check that the rear wheels are sound and moving freely. If a

wheel is found to be loose or damaged then the floor sander

will not sand or handle properly. Check and reset the wheels

(see Setting the Wheels on page 8). Replace damaged

wheels.

7. Check the condition of the Dust Bag Frame making sure that

it hinges down in to its operating position and locks securely

when stowed.

Dust Control

1. Remove the handle and lay the floor sander on its face.

Remove the sanding pad if fitted and inspect the underside for

the build up of dust or pieces of abrasive. Clean as required.

2. Inspect the condition of the Dust Brush. The brush should be

replaced if damaged or badly worn.

Drive

1. The dive gears and drive belt do not require maintenance

under normal operating conditions.

Lubrication

1. The HTF-2 Floor Sander features sealed for life bearings

which do not require any lubrication. In the unlikely event that

a bearing has to be replaced use a Hiretech genuine spare

part only as the grease contained in the bearings is special.

A standard bearing is not suitable and may result in further

damage.

Care of Motor

1. The motor must be kept clean and free from grease and dust.

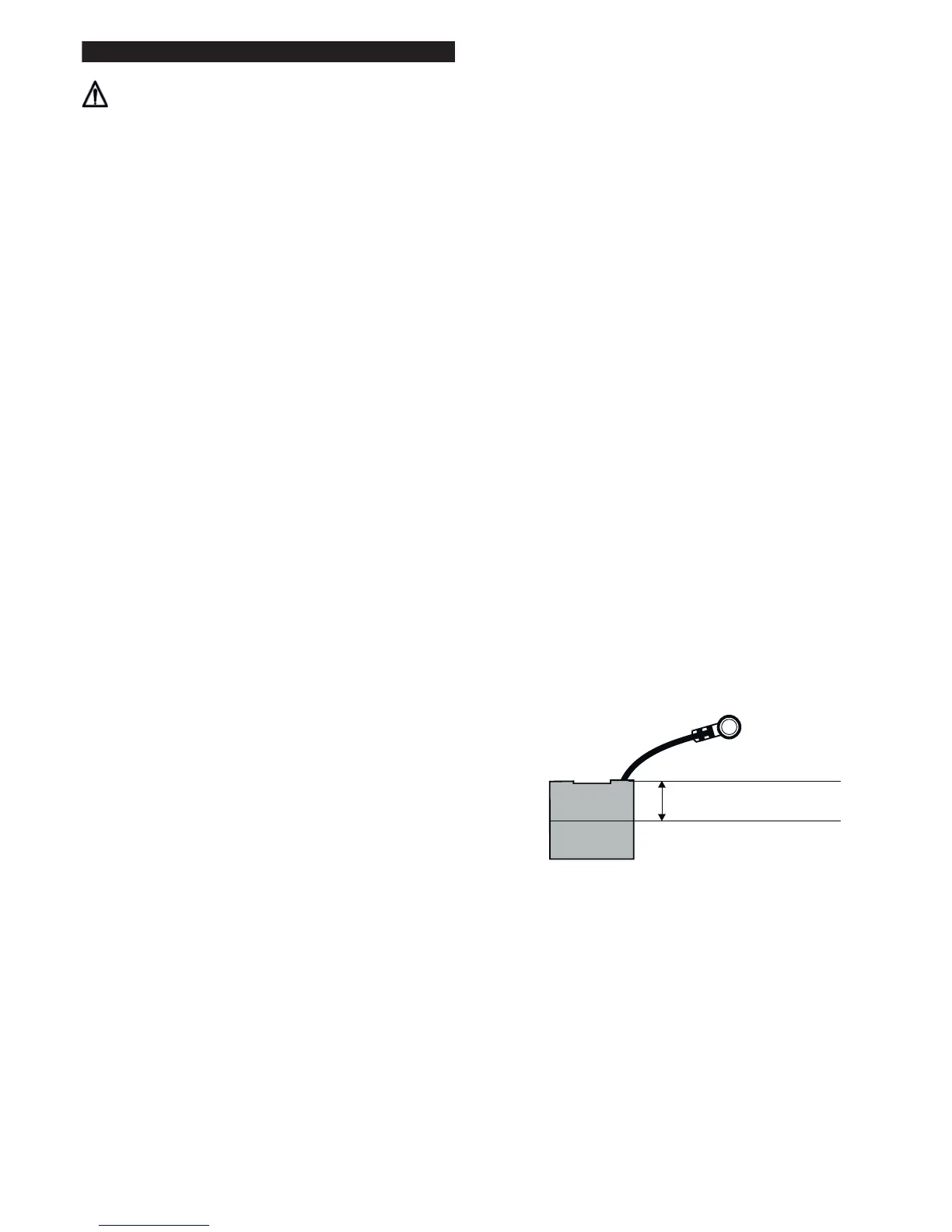

2. The motor brushes must be checked regularly. Replace

ALL FOUR motor brushes when any one brush has worn to

12mm (1/2”) or less in length. Brushes MUST slide freely in

the brush holders.

There is no need to remove or disconnect any internal leads

when changing the brushes, only the small braided shunt

(pigtail) connected to the motor brush is disconnected to

release the brush.

3. To replace the motor Brushes ;

i. Remove the four screws from the Motor Cover and lift the

cover off.

ii. Remove the four Spring Brushes and set to one side. The

springs are removed by pushing the spring tag in towards

the brush and lifting out.

iii. Using a cross recess screwdriver remove the four brush

shunt (pigtail) retaining screws and lock washers.

iv. Remove the four brushes.

v. Thoroughly clean the brush assembly and housing using

a soft brush and a suitable vacuum cleaner.

vi. Inspect the four brushes for damage or wear and if any

one brush is found to be damaged or worn to a length

of 12mm (1/2””) or less in length then replace all four

brushes. Always replace all four brushes together.

Motor Brush

vii. When replacing brushes ensure that each brush moves

freely in each brush holder and fit the brush with the shunt

(pigtail) in such a position as to allow free movement

throughout the brushes life. Ensure that each brush shunt is

connected securely with the screw and lock washer (two

spare screws and washers are provided with each pack

of brushes). The brush should be fitted so that the brush

shunt (pigtail) is at the bottom of the brush.

viii. Refit the brush springs by inserting into the holder with the

coil spring over the brush then push in until

the tag comes into contact with the holder, slide the tag

away from the brush and release. The brush spring will

clip into position. Check the springs and brushes for

correct alignment and free movement.

ix. Finally check that all leads and cables are clear of

moving parts and will not be trapped when refitting the

cover motor.

Minimum Brush Length

12mm ( /” )

1

2

7

© Hiretech

Loading...

Loading...