--- 40 ---

11-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to following items.

(1) Prior to reassembly, measure the insulation resistance of the armature, stator, switch and other electrical

components and confirm that the insulation resistance of each part is more than 7 M Ω.

(2) When replacing the Spring [155], apply approximately 5 grams of Hitachi Motor Grease to the inner

circumference of the new spring prior to assembly.

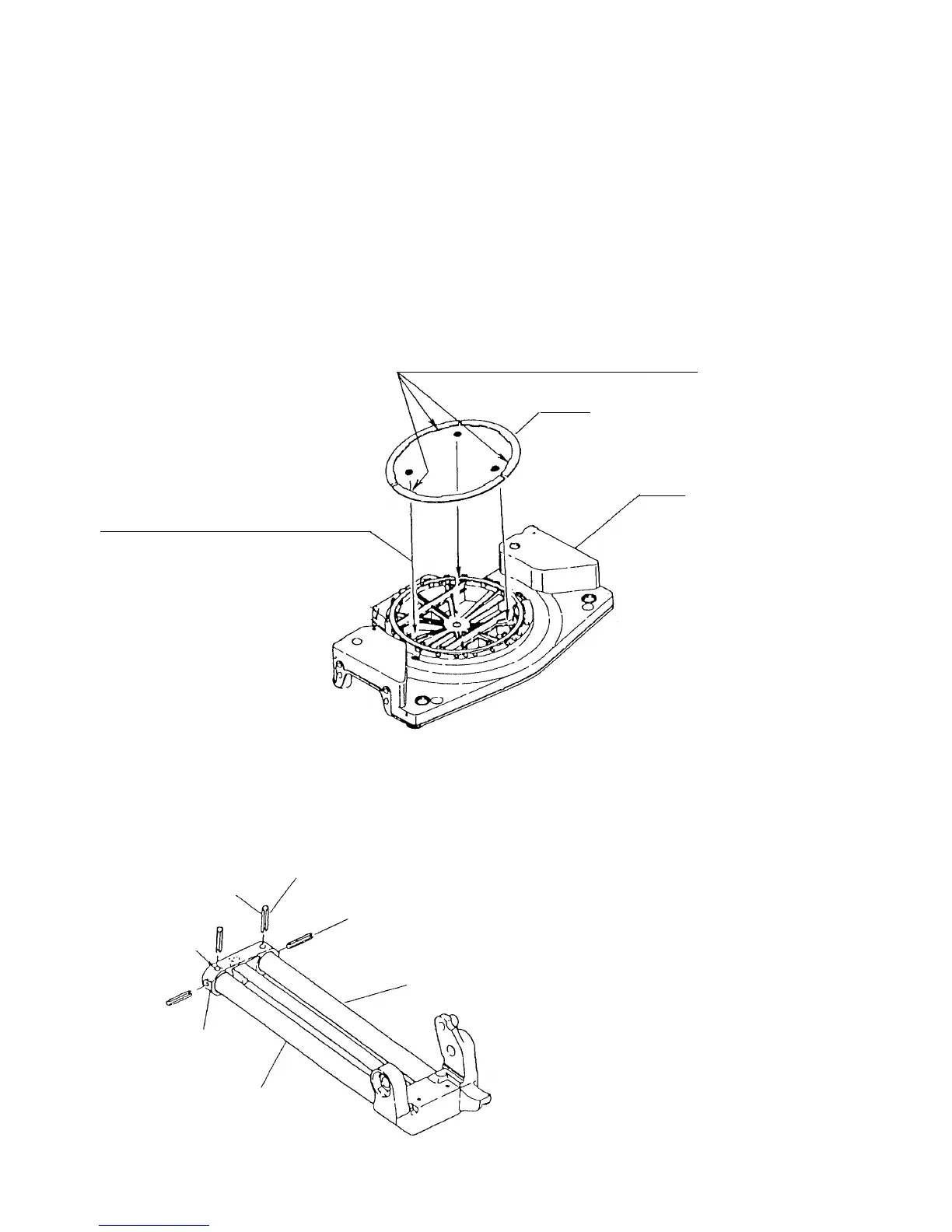

(3) When replacing or reassembling the Liner [46A], ensure it is positioned and assembled as illustrated in Fig.

68. In addition, coat approximately 8 grams of Hitachi Motor Grease on the liner sliding portion of the Turn

Table [9A].

This process is necessary to prevent slide

pipe (A) and slide pipe (B) from twisting in

the holes. (For later reassembly, new dia.

6 mm holes need not be drilled. Insert the

Roll Pins D6 x 40 [60] through the dia. 6 mm

holes drilled before.)

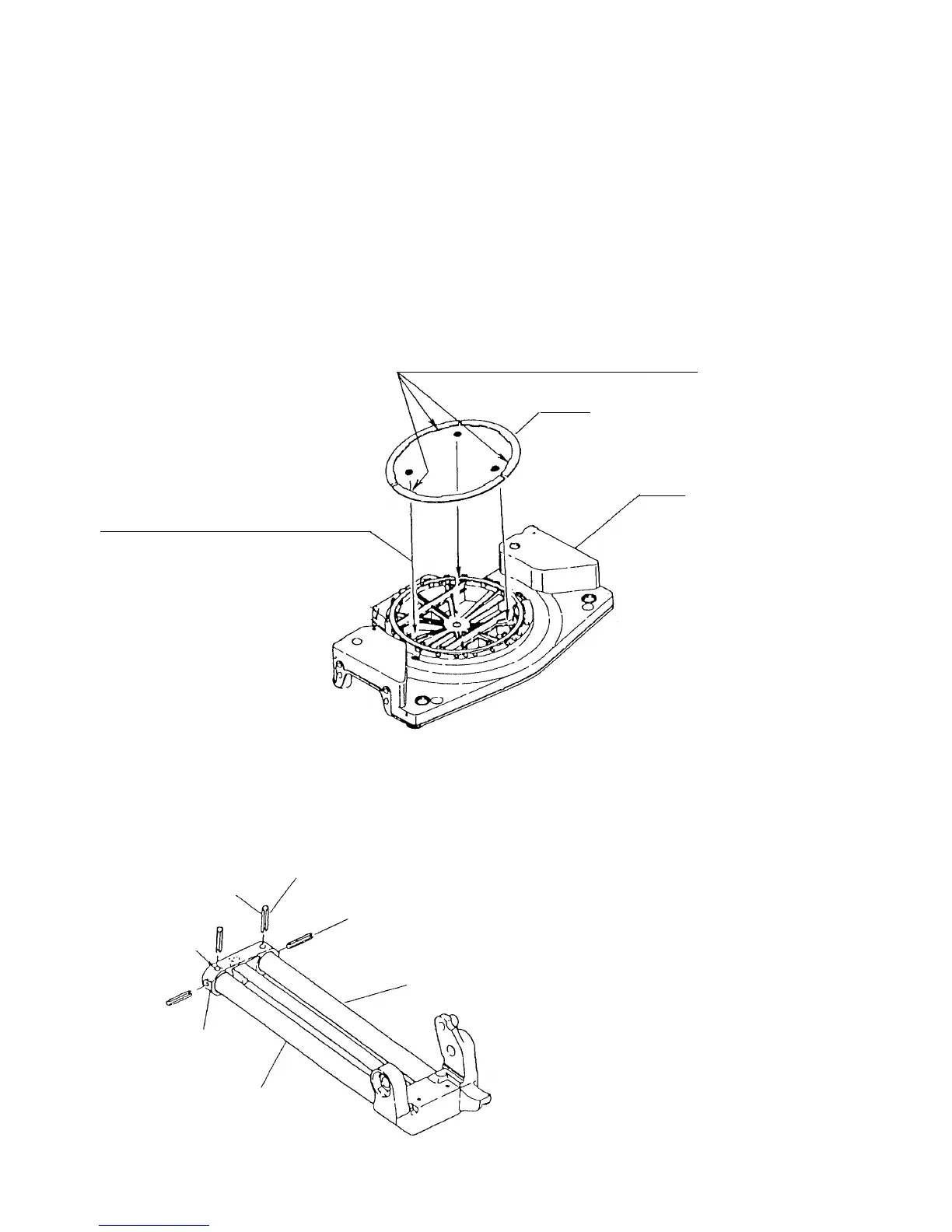

(4) When replacing the Hinge Ass'y [51] or Support [61], after press-fitting the Hinge Ass'y [51] onto slide pipe (A)

and slide pipe (B), drill dia. 6 mm vertical holes for insertion of the two Roll Pins D6 x 40 [60].

Fig. 68

Position the wide collar portions as indicated.

The raised portions of the base must be

aligned with the joints of the liner.

Liner

Base

6 mm dia.

drill hole

Orientation of roll pins to be

inserted when replacing the

hinge or support

Factory-set orientation

of roll pins

Slide pipe (A)

Slide pipe (B)

Support

Roll pin D6 x 40

Fig. 69

Loading...

Loading...