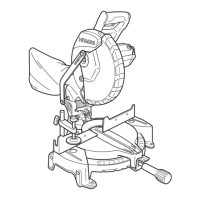

PRODUCT NAME

Hitachi Slide Compound Miter Saw

Models C 8FSE, C 8FSHE

Cutting various types of wood workpieces

Cutting workpieces of plywood, decoration panels, soft fiberboards and hard boards

Cutting aluminum sashes

The new slide compound miter saws Models C 8FSE and C 8FSHE are developed to bring to the European

market at the prices as low as the competitors’ products. The Model C 8FSHE is equipped with a laser marker

for easier alignment with the ink line and an LED light to illuminate the working surface brightly. In addition, the

Model C 8FSE that is mostly the same as the Model C 8FSHE except that it is not equipped with the laser

marker and the LED light is introduced in tandem with the Model C 8FSHE. With the new Models C 8FSE and

, we aim to enhance the share of

MARKETING OBJECTIVE

APPLICATIONS

SELLING POINTS

International Sales Division

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

LIST Nos.

C 8FSE: E948

C 8FSHE: E949

Feb. 2008

C 8FSHE

C

<Same features as the conventional models>

Slide cutting

Press cutting

Miter cutting

Right and left bevel cutting

Compound miter and left bevel cutting

Splinter guard, also serving for cut alignment

Groove cutting

[ NEW FEATURES ]

Laser marker (Only the Model C 8FSHE)

LED light (Only the Model C 8FSHE)

Lightweight

Positive angle stoppers

Bevel cutting range: Left 48° to right 5°

High dust collecting performance

Soft grip handle

Legible scale